Abstract

Background:

With the outbreak of COVID-19 disease to reduce the risk of disease transmission, increasing the level of automation (LoA) in manufacturing and services is the concern of many managers.Objectives:

The purpose of this article is to provide a new definition of LoA, considering the increasing use of enterprise resource planning (ERP) systems and modern technologies such as blockchain and the internet of things (IoT).Methods:

First, different generations of ERP systems were studied and three components of information, system, and human were identified in it, then the components of each class were studied and the solutions used in each component were examined. In the continuation of the research, the previous definitions of LoA were reviewed and the existing research gap was identified and the definition of new automation levels was presented. In this research, the Delphi method was used. For validation, the new definition of LoA was adapted to the definition performed by Verplank and Sheridan.Results:

New LoA definition by considering the latest technologies in the world for use in production and service centers. Determining the LoA of a medical center and proposing the optimal level of the desired center with the available resources.Conclusions:

The new LoA definition can help improve the LoA of medical centers practically.Keywords

Automation Level of Automation ERP New Technologies COVID-19

1. Background

Automation is the process of enabling machines to perform a series of predetermined operations without human intervention or minimal intervention, as well as the use of special equipment that operates and controls industrial operations. Today, the use of automation in manufacturing and services to increase production, reduce costs, improve product quality or service, optimize the use of raw materials, reduce energy consumption, increase profitability, create a safe environment for employees, and reduce environmental pollution is necessary. Interactions between humans and systems and the cooperation between them are defined by different levels of automation (LoA).

For the first time, Verplank and Sheridan (1) defined ten levels of automation for industries, based on six activities that humans and systems perform in the production process, including getting, selecting, starting, requesting, approving, and notifying.

Then other one-dimensional definitions of automation levels were performed (2-12). Riley (13) considered a 2D matrix, that its rows show the levels of automation while the columns of which correspond to the dimensions of automation. Cabrall et al. (14) suggested a four-dimensional definition of the operation of an automated vehicle in several simultaneous dimensions including (1) location (from location to location), (2) identity (between human and computer), (3) degree of focus (control) and finally (4) adaptive optimization over time. Vagia et al. (15) reviewed the previous definitions in a literature review study and then presented a new definition of levels of automation at five levels based on the commonalities of the previous definitions. The most important definition of LoA is the one provided by the Automotive Engineers Association (16) for the automotive industry. With the rise of the Coronavirus increasing the LoA to reduce the risk of transmission of the Coronavirus to service providers and consumers is noted by managers, and research shows that organizations that have previously used automation in production processes have suffered the least damage. COVID‐19 has done the least amount of disruption possible in industries where automation solutions were deployed previously. For example, Amazon’s heavy investment in robotic automation within its fulfillment centers proved worthwhile because it allowed robust shipment of crucial medical supplies to hospitals and household staples to homes of people ordered to stay indoors (17). Autonomous long‐haul trucking, self‐piloting ships, and automated cranes are emerging technologies that were highly advantageous in this crisis (18). And also for providing face masks, gloves, and other items that must be produced in a particular environment without manual intervention, autonomy provides an automated solution to various manufacturing challenges and can fulfill the customized requirements of face masks, gloves, and other items (19). In automation, the role of the human factor decreases, and the rate of disease transmission lessens. So, factories are forced to use automation to decrease the transmission of COVID-19 and continue production.

To increase the LoA in organizations, it is necessary to measure the current LoA then according to the needs, capabilities of the organization, and, available resources in different areas LoA improvement should be done. Because enterprise resource planning (ERP) systems help to reduce costs and increase quality and production in manufacturing and service industries by integrating information, they have been considered by managers of organizations and have been widely used in various industries. Given the advances that have been made in ERP systems and are used in most manufacturing and service organizations, it is necessary to use the concepts of ERP systems in the new LoA definition. Also, the use of new technologies such as blockchain and internet of things (IoT) in computer systems has increased security and ease of use and has been widely used in new generations of ERP (20, 21).

2. Methods

2.1. Level of Automation Definition

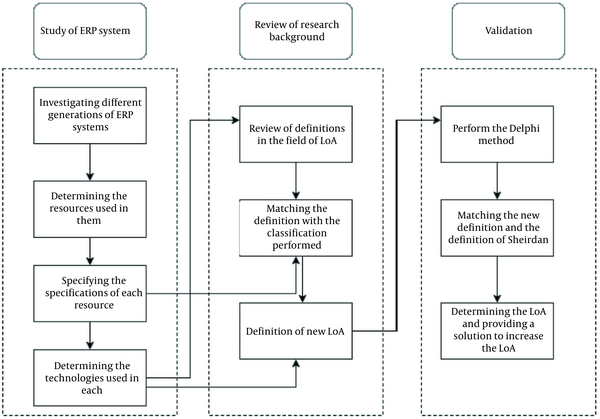

First, ERP systems and their different generations were studied, and then the resources needed to implement the ERP system were identified and classified. To run an ERP system, information is used as system input and for processing. The operator and the system interact to perform processes and execute commands. Then, in each category, the factors affecting the system were studied. Also, the definitions of automation levels were classified according to the parameters obtained from the previous section. By adapting the LoA definition to the parameters used in ERP systems, finally, a new definition of automation levels was introduced. The Delphi method was used to confirm the definition. To validate the new LoA definition, this definition was adapted to the definition of Verplank and Sheridan, and its validity was confirmed (1). Then the new definition was implemented in a medical center and its LoA was determined. To improve the LoA, the minimum and maximum applicable LoA were determined and suggestions were made to improve the LoA. Figure 1 shows the steps to do the research.

Research process

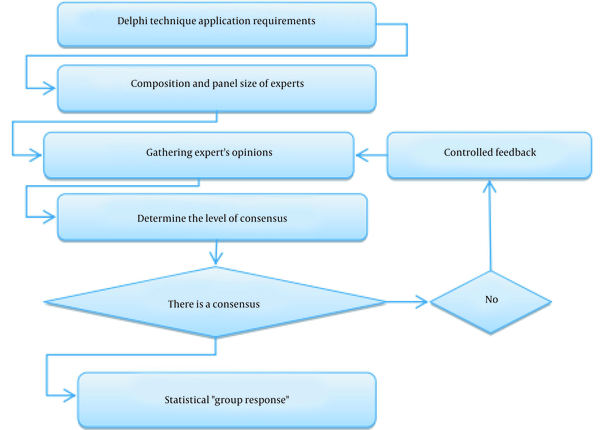

2.2. Delphi Method

The Delphi method has been used to confirm the definition of the desired LoA (Figure 2).

Delphi method (22)

2.3. Society and Statistical Sample

The statistical population of the present study is experts in the field of information systems, health information technology, public sector information technology, and industrial engineering experts. Also, like any other type of sampling, the sample size depends on factors such as accessibility, time, and cost of data collection. However, the number of panel members in previous studies has varied between 10 and 30. However, when the panel members are homogeneous, about 10 to 20 members are recommended. In the Delphi study, if the participants are homogeneous, 10 to 15 samples will suffice to perform Delphi (23). Accordingly, to maintain the validity of the research and consider the decline of respondents during the study, about 30 people were identified, and after filtering and applying the indicators, a list of 24 people was announced. In the first round of the Delphi method, 20 people participated and among the collected questionnaires, 18 sheets were returned and used. Fifteen people participated in the second round and 13 people in the third round. In the present study, the Kendall coordination coefficient was used to examine the degree of consensus and coordination of panel members. The test provides a number between zero and one, zero indicating disagreement (independence and inconsistency), and number one indicating complete agreement and correlation. To perform the Kendall test (Table 1), in the first stage, test hypotheses were developed. In Hypothesis H0, disagreement between experts’ opinions on the definition of new LoA was claimed, and in Hypothesis H1, an agreement between experts’ opinions was claimed.

| W | Interpretation | Rank Confidence |

|---|---|---|

| 0.1 | No agreement | No |

| 0.3 | Weak agreement | Low |

| 0.5 | Moderate agreement | Middle |

| 0.7 | Strong agreement | High |

| 0.9 | Perfect agreement | Very high |

2.4. Validation

After confirming the new LoA definition by the Delphi panel, it was adapted to the definition of Verplank and Sheridan (1).

2.5. Case Study

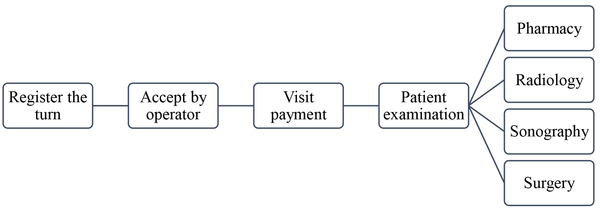

New LoA definition was implemented in a medical center belonging to medical sciences in which the second generation ERP system was installed. In this medical center, patients receive numbers through the devices installed in the hospital and then go to the reception area and give the authentication documents to the employee. The relevant person confirms the information, and the system inquires about the patient’s insurance and calculates the amount of the visit. The patient goes to the fund and pays for the visit. The system gives the patient a turn. Then the patient goes to the doctor’s office and waits until his turn. After the examination, the doctor registers the information in the patient’s file, and the case of need for other services such as drugs, consultation with other doctors, radiology, sonography, surgery, etc., registers the request in the system (Figure 3). The patient then refers to the relevant office and completes the admission process as in the previous section. After performing additional tests and examinations, the results are recorded in the patient’s file. In the case of surgical registration, the required instructions are registered in the system and the operating room is reserved on the desired day. Then the LoA in the desired medical center was calculated using the new LoA definition.

The process of performing services in the hospital

3. Results

3.1. Level of Automation Definition

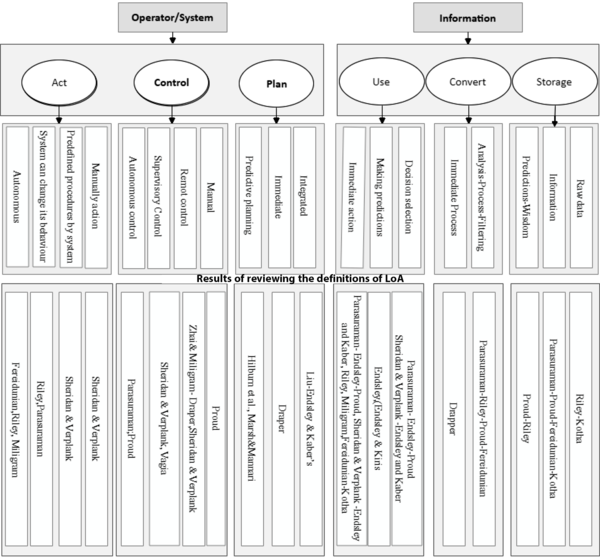

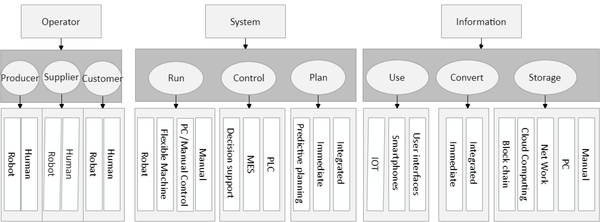

Examining the research background and definitions performed at automation levels, it was concluded that the definitions performed so far focus on two aspects of information and operations. Operations performed by the system include three types of control, planning, and execution of operations/services. In the field of information, three categories of saving information, data conversion, and information uses were identified. In the following, different generations of ERP systems and technologies used in each of them were examined according to the classifications of automation levels. The technologies used and how they work are shown in Figure 2. In the save information section, three methods of raw or unprocessed data storage, data storage, and data forecasting storage are used, which changes as the system progresses. In the field of information conversion, methods of analysis, processing, and filtering are used, and in high levels of automation, immediate processing is used. In the use of information, methods of decision selection, forecasting, and immediate execution of orders were identified. In the continuation of the research, which is shown in the lower part of Figure 4, after reviewing the literature related to the definitions done at LoA, the names of the researchers who have used the information in their definitions are given.

Investigating the effective factors in the implementation of the enterprise resource planning system

Then, equipment that is used in ERP systems in each section was studied. The results are shown in Figure 3. At the information level at low LoAs, data storage is done manually, at higher LoAs computer systems are used, and in advanced systems, computer networks, cloud computing, and blockchain technology are used, respectively. Information conversion is also done collectively and immediately. The user interface, smartphones, and IoTs can be used to use the information. In planning, methods of information aggregation, online planning, and planning with predictability are used. In advanced control systems for commands control, programmable logic controller (PLC), manufacturing execution system (MES), and decision support (DS) are used. Humans, human-controlled computers, human-programmed concept systems, and robots are also used in advanced systems to execute commands, respectively.

Finally, according to the information obtained from Figure 5 and the classifications performed, the LoA was extracted as shown in Table 2.

Technologies used in enterprise resource planning systems

The New Definition of Automation Levels Using New Technologies

| Level of Automation | Information | Plan | Control | Act |

|---|---|---|---|---|

| 1 | Manual | Manual | Manual | |

| Storage | Manual | |||

| Convert | Manual | |||

| Use | Manual | |||

| 2 | Manually with the help of the system | Manually with the help of automation equipment such as programmable logic controller | Manually with the help of the system | |

| Storage | Manually with the help of the system | |||

| Convert | Manually with the help of the system | |||

| Use | Manually with the help of the system | |||

| 3 | Manually with the help of the system immediately | Manually with the help of automation equipment such as manufacturing execution system | Manual with the help of a flexible system | |

| Storage | Manual data entry/storage by network | |||

| Convert | System/integrated | |||

| Use | System/smartphone | |||

| 4 | Predictable system | Decision support system and enterprise resource planning system | Robot | |

| Storage | System/cloud Processing/blockchain | |||

| Convert | System/immediately | |||

| Use | Internet of things |

The definition is presented in four dimensions and four levels. The first level is manual in all four dimensions and is performed by the operator. In the second level, the processes are performed jointly between the operator and the system, and the role of the operator in the system is very strong. At this level, ordinary computers, PLC, and second-generation ERP systems are used. In the third level, computer networks, MES, and the third generation ERP systems are used. In the fourth level, blockchain and cloud technology are used to store information. At this level, information processing is performed immediately and the equipment uses the Internet of Things to use the information. Planning is based on artificial intelligence and forecasting systems. The fourth-generation ERP system and decision support systems are used to control and robots are used to execute commands.

3.2. Delphi Method

Then for confirming the result used the Delphi method. The results of the three rounds of the Delphi method are given in Table 3. The fact that the value of the Kendall rank correlation coefficient in the third round was more than in the second round by only 0.45 shows that the levels of agreement among the experts did not considerably different in the two rounds. For this reason, the Delphi method stopped after the third round. The weight in the final round of the Delphi method was W = 0.704, implying a strong agreement among the experts on the new LoA definition.

Delphi Result

| Result | First Round | Second Round | Third Round | |||

|---|---|---|---|---|---|---|

| Average | Standard Deviation | Average | Standard Deviation | Average | Standard Deviation | |

| Confirm the results | 4.1 | 0.804 | 4.2 | 0.59 | 4.3 | 0.46 |

Considering that the critical value and significance level for testing the hypotheses (2.3) is equal to 0.05 and since the value of sig is zero and less than five percent, H0 was rejected and the claim of the experts on H1 was accepted. Also, in the present study, the number of Delphi panel members was between 13 - 18 and the value of the coefficient calculated in the final round of Delphi was 0.804 W and based on the information in Table 1, a very strong coordination and consensus about the new LoA definition can be observed.

3.3. Validation

For the above definition, the desired definition was adapted to the definition of Verplank and Sheridan (1). The results are shown in Table 4. As can be seen, level two of both definitions are the same. In the second, third, and fourth levels of Verplank and Sheridan’s definition, the system suggests to the operator to perform activities that these two levels correspond to the second level of the new definition and is possible using PLC equipment (1). Levels 5 to 9 of the definition of Verplank and Sheridan’s definition are possible using MES equipment, and finally, a fully automatic level can be implemented by the robot and the ERP system (1).

Validation of the New Definition of Level of Automation

| Information | Plan | Control | Act | Verplank and Sheridan’s Definition (1) |

|---|---|---|---|---|

| M | M | M | M | Fully manual control |

| M/S | M/S | M/ programmable logic controller | M/S | The computer offers a complete set of decision/action alternatives |

| M/S | M/S | M/ programmable logic controller | M/S | The computer narrows the selection down to a few |

| S | M/S | M/ programmable logic controller | M/S | The computer suggests one alternative |

| M/S | M/S/I | S/MIS | M/Flexible S | The computer executes that suggestion if the human approves |

| M/S | M/S/I | S/MIS | M/Flexible S | The computer allows the human a restricted time to veto before automatic execution |

| M/S | M/S/I | S/MIS | M/Flexible S | The computer executes automatically, then necessarily informs the human |

| M/S | M/S/I | S/MIS | M/Flexible S | The computer informs the human only if asked |

| M/S | M/S/I | S/MIS | M/Flexible S | The computer informs the human only if it decides to |

| S/cloud/blockchain | Predictable system | Decision aupport S | Robot | Fully autonomous Control |

3.4. Case Study

The LoA in a desired medical center was calculated using the new LoA definition (Table 5).

Determining the Level of Automation in a Medical Center

| Process | Information | Plan | Control | Act | Min LoA | Max LoA |

|---|---|---|---|---|---|---|

| Register the turn by patient | 3 | 3 | 3 | |||

| Storage | 3 | 2 | 4 | |||

| Convert | 3 | 2 | 4 | |||

| Use | 3 | 2 | 4 | |||

| Accept by operator | 3 | 3 | 3 | |||

| Storage | 2 | 2 | 4 | |||

| Convert | 2 | 2 | 4 | |||

| Use | 2 | 2 | 4 | |||

| Visit payment | 3 | 3 | 3 | |||

| Storage | 3 | 2 | 4 | |||

| Convert | 3 | 2 | 4 | |||

| Use | 3 | 2 | 4 | |||

| Patient examination | 3 | 3 | 3 | |||

| Storage | 3 | 2 | 4 | |||

| Convert | 3 | 2 | 4 | |||

| Use | 3 | 2 | 4 | |||

| Pharmacy radiology sonography | 3 | 3 | 3 | |||

| Storage | 3 | 2 | 4 | |||

| Convert | 3 | 2 | 4 | |||

| Use | 3 | 2 | 4 | |||

| Surgery | 3 | 3 | 3 | |||

| Storage | 3 | 2 | 4 | |||

| Convert | 3 | 2 | 4 | |||

| Use | 3 | 2 | 4 |

As can be seen, the LoA in the medical center in question is 3 in most processes. Both the operator and the system do the work, and the presence of an operator is necessary to do the work. To improve the LoA, it is suggested the appointment be automatically done after the patient registers the request through the system from home. The patient identification and insurance are done automatically, and the amount of the visit will be calculated and paid by the bank portal. It is also possible to automatically deduce the amount of the visit from the patient’s account by registering the patient’s bank account information in the system. In this way, the LoA in the two processes of confirmation of turn and payment of visit is upgraded and the operator is removed from the desired process. In the case of payment for visits to paraclinical services and operating rooms, the operator can also be removed. In the case of patients with a history of certain diseases, such as diabetes and hypertension who need to renew the drug at regular intervals, information can be entered into the system by controlling diabetes or blood pressure through a device in the patient’s home and the doctor can control the desired values. By prescribing the patient’s medications, there is no need for the patient to be present in the medical center. In the operating room process, the presence of doctors in the operating room can be reduced by using surgeon robots. In the process of taking the result of the paraclinical services, there is no need for the patient to be present to receive the answer, and if there is a need to perform the test again, the patient will be notified via SMS and the turn will be registered in the system again.

4. Discussion

In this research, a new definition of LoA has been presented considering the ERP systems and new technologies. Then, in a medical center, the desired definition was used. First, the current LoA was obtained and, suggestions were made to increase the LoA. In the previous LoA definitions, there was no news of the latest technologies in the world. Also, due to the use of ERP systems in organizations and their importance, the relationship between ERP systems and LoA was not considered. The desired definition is done in 4 dimensions (information, plan, control, act) and more carefully selects the level of automation. Also, no research has been done to determine the LoA in medical centers.

This definition is used in organizations where the ERP system is implemented.

For future research, the processes of a completely manual hospital system can be examined that has no ERP system. Mathematical modeling can also be used to solve the problem.

4.1. Conclusions

To increase LoA, managers of organizations can use the new definition of LoA to calculate the current LoA in four dimensions of the organization to accurately calculate the level of automation, then improve the current LoA according to the resources available in various dimensions. Given the advances that have been made in the use of ERP systems and modern technologies, the use of these technologies in the definition of LoA is essential and provides a clear picture of the state of the organization. The prospects for using modern technologies such as blockchain and cloud computing are also visible at high levels of automation, respectively.

To further explore the desired definition, the new definition was implemented in a medical center and its LoA was calculated. Improving LoA using new technologies can achieve better results and save time and money in the organization. For example, in this case study, to improve LoA, surgeon robots or decision support systems can be used.

References

-

1.

Verplank WL, Sheridan T. Human and Computer Control of Undersea Teleoperators. Massachusetts, USA: Massachusetts Inst of Tech Cambridge Man-Machine Systems Lab; 1978, [cited 2022]. Available from: https://apps.dtic.mil/sti/citations/ADA057655.

-

2.

Clough B. Relating Autonomy To a Task: Can It Be Done? 1st UAV Conference. Virginia, USA. 2002.

-

3.

Draper JV. Teleoperators for advanced manufacturing: Applications and human factors challenges. International Journal of Human Factors in Manufacturing. 1995;5(1):53-85. https://doi.org/10.1002/hfm.4530050105.

-

4.

Endsley MR, Kaber DB. Level of automation effects on performance, situation awareness and workload in a dynamic control task. Ergonomics. 1999;42(3):462-92. [PubMed ID: 10048306]. https://doi.org/10.1080/001401399185595.

-

5.

Fereidunian A, Lucas C, Lesani H, Lehtonen M, Nordman M. Challenges in implementation of human-automation interaction models. Mediterranean Conference on Control & Automation. Athens, Greece. 2007. p. 1-6.

-

6.

Lorenz B, Di Nocera F, Röttger S, Parasuraman R. The Effects of Level of Automation on the Out-of-the-Loop Unfamiliarity in a Complex Dynamic Fault-Management Task during Simulated Spaceflight Operations. Proceedings of the Human Factors and Ergonomics Society 45th Annual Meeting. California, USA. 2016. p. 44-8.

-

7.

Mehta A, Subramanian M. Investigating the barriers to increase Levels of Automation: A case study in pre-assembly of tap changer assembly line. 2019.

-

8.

Ntuen CA, Park EH. Human factor issues in teleoperated systems. Proceedings of the First International Conference on Ergonomics of Hybrid Automated Systems I. Kentucky, U.S.A. Elsevier; 1988. p. 203-10.

-

9.

Ntuen CA. Human interaction with complex systems: conceptual principles and design practice. 372. 1st ed. Berlin/Heidelberg, Germany: Springer Science & Business Media; 1996.

-

10.

Proud RW, Hart JJ, Mrozinski RB. Methods for determining the level of autonomy to design into a human spaceflight vehicle: a function specific approach. Launch Vehicles and Launch Operations. Texas, USA. National Aeronautics and Space Administration Houston TX Lyndon B Johnson …; 2003. 15 p.

-

11.

Westin C, Borst C, Hilburn B. Automation Transparency and Personalized Decision Support: Air Traffic Controller Interaction with a Resolution Advisory System. IFAC-PapersOnLine. 2016;49(19):201-6. https://doi.org/10.1016/j.ifacol.2016.10.520.

-

12.

Zhai S, Milgram P. Telerobotic virtual control system. 1612. Massachusetts, United States: SPIE; 1992. OE p.

-

13.

Riley V. A General Model of Mixed-Initiative Human-Machine Systems. California, USA. 1989. p. 124-8.

-

14.

Cabrall C, Sheridan T, Prevot T, de Winter JCF, Happee R. The 4D LINT Model of Function Allocation: Spatial-Temporal Arrangement and Levels of Automation. International Conference on Intelligent Human Systems Integration. Modena, Italy. 2018. p. 29-34.

-

15.

Vagia M, Transeth AA, Fjerdingen SA. A literature review on the levels of automation during the years. What are the different taxonomies that have been proposed? Appl Ergon. 2016;53 Pt A:190-202. [PubMed ID: 26467193]. https://doi.org/10.1016/j.apergo.2015.09.013.

-

16.

On-Road Automated Driving (ORAD) committee. Taxonomy and definitions for terms related to driving automation systems for on-road motor vehicles. On-Road Automated Driving (ORAD) committee. SAE International; 2021.

-

17.

Ackerman ME. [COVID-19 (coronavirus) and the employment relationship]. Revista de Derecho Laboral Actualidad. 2020:7. Spanish.

-

18.

Malik AA. Robots and COVID-19: Challenges in integrating robots for collaborative automation. arXiv. 2020.

-

19.

Javaid M, Haleem A, Vaishya R, Bahl S, Suman R, Vaish A. Industry 4.0 technologies and their applications in fighting COVID-19 pandemic. Diabetes Metab Syndr. 2020;14(4):419-22. [PubMed ID: 32344370]. [PubMed Central ID: PMC7180383]. https://doi.org/10.1016/j.dsx.2020.04.032.

-

20.

Tavana M, Hajipour V, Oveisi S. IoT-based enterprise resource planning: Challenges, open issues, applications, architecture, and future research directions. Internet Things. 2020;11:100262. https://doi.org/10.1016/j.iot.2020.100262.

-

21.

Rajendra R. 60 Must-Know ERP Statistics Before Making a Buying Decision. Learn hub. 2021.

-

22.

Habibi A, Sarafrazi A, Izadyar S. Delphi Technique Theoretical Framework in Qualitative. Int J Eng Sci. 2014;3:8-13.

-

23.

Gupta UG, Clarke RE. Theory and applications of the Delphi technique: A bibliography (1975–1994). Technol Forecast Soc Change. 1996;53(2):185-211. https://doi.org/10.1016/s0040-1625(96)00094-7.

-

24.

Abdi H. The Kendall rank correlation coefficient. Encyclopedia of measurement and statistics. 2007;2:508-10.