Abstract

Background:

Loading of petroleum products consists of several parts, of which the arm platform section is known to be the source of most accidents.Objectives:

Therefore, this study was done to evaluate the risk of arm loading platforms using the bow-tie analysis (BTA) technique to identify the causes and the probability of occurrence of hazardous events.Methods:

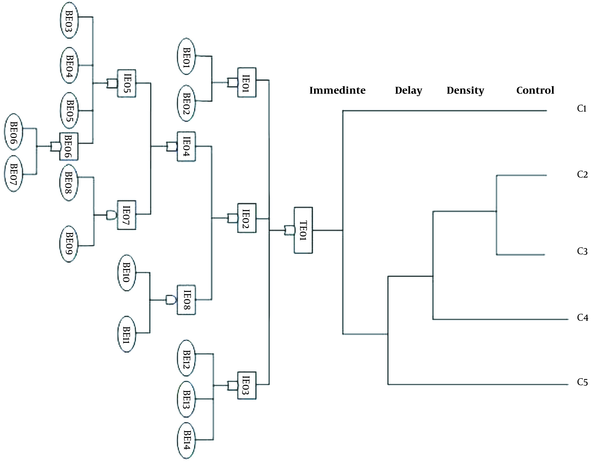

In this study, we first identified the risks of the loading arm using the expert’s judgment. The risk of overflow is considered as the top event. Then, the basic events were identified by the fault tree analysis (FTA), and the possible consequences of the top event were predicted using the event tree. Next, using the computational equations, the probability of spillover and its consequences were calculated. The path of the risk event from the causal phase to the consequent phase was also illustrated by sketching the structure of the BTA.Results:

A total of 14 basic events and 8 intermediate events were involved in the occurrence of the top event, and 5 consequences were identified for the risk of spillover. The probability of the top event occurring was calculated to be 3.12 × 10-7.Conclusions:

According to the results of this study, tank overflow is one of the most important hazards in the loading arm section.Keywords

Risk Assessment Loading Arm BTA Technique Petroleum Product Expert Elicitation

1. Background

The oil and gas industries are prone to catastrophic events due to dealing with hazardous materials. Therefore, effective risk analysis in these industries is necessary to prevent accidents and provide control strategies (1).

Loading arms are the most important part of loading operations in petroleum products. The severity of accidents in these departments depends on the type of petroleum product, the chemical properties of the product, the duration of exposure, and environmental conditions (2). There are a variety of potential hazards to the loading platform's arm causing numerous accidents, including product leaks, fires, and explosions during loading operations that could result in casualties, financial losses, and severe environmental pollutions. Therefore, performing a risk assessment and identifying the key factors leading to accidents in the loading arms is important to ensure the safety performance of the system in this area (3).

Different techniques are used for risk analysis in industries. Fault tree analysis (FTA), preliminary hazard analysis (PrHA), and bow tie analysis (BTA) are some tools that are used in risk analysis. These techniques provide risk assessment for a specific purpose. Therefore, different inputs and outputs are the most prominent distinction in applying these techniques (4).

BTA technique is one of the risk assessment tools in complex systems. This technique integrates the relationships between hazards, events, and potential consequences of an accident into a clear chart (5). This technique can provide a simple and comprehensible portrayal of effective risk assessment scenarios and a logical relationship between causes and consequences in the form of a chart (6). The BTA technique has been used for risk management purposes since the 1970s (7). For example, Khakzad et al. used BTA to analyze safety risks in offshore drilling operations (8). Xu and Xu used the BTA technique for risk assessment in mining (5). Finally, Yao Zhang and Xin Guan selected project prevention and conservation strategies based on the results of the BTA (9).

On the basis of the importance of the safety of oil and petroleum processes and the occurrence of disasters, such as piper alpha, it seems that attention to this subject is necessary. Iran has great oil reserves, and the safety of oil industries is needed to be attended more than ever. Explosion or any type of accident in this area can impose a large amount of damages; therefore, it is better to avoid any accident. Based on our knowledge, no study has yet been conducted to evaluate the risk of loading arms using the BTA technique. The study of loading arms of platforms is a new field of research.

2. Objectives

The purpose of this study was to evaluate the risk of loading arm of petroleum products using the BTA technique.

3. Methods

The present research was a cross-sectional study conducted in the arm section of loading platforms for oil product distribution. The steps of the study were as follows:

3.1. Risk Analysis

In the first stage, expert elicitation was used to determine the basic events. Each expert was given a weight based on his/her experience, level of knowledge, and professional position. In the next phase, the basic events were determined by direct observation as well as consultation with experts and operators. Each expert was then asked to perform a linguistic assessment for each basic event. The results of the linguistic evaluation are presented in Table 1. Eventually, the linguistic terms of the experts became triangular fuzzy numbers.

Experts’ Opinions on Basic Events

| Tags | Event | Expert 1 | Expert 2 | Expert 3 |

|---|---|---|---|---|

| BE01 | Incorrect volume given to meter | RL | RL | M |

| BE02 | The volume recorded in the bill of lading does not fit the tanker type | L | L | L |

| BE03 | Adverse effects of environmental conditions | RL | L | L |

| BE04 | Meter burnout due to over-operation | L | L | L |

| BE05 | Defect in the diaphragm valves | L | L | L |

| BE06 | Turning on the pumps simultaneously | RL | RL | M |

| BE07 | The meter is set incorrectly | L | L | L |

| BE08 | Defect in rotation of bearing | RL | RL | L |

| BE09 | Locking the handle of the meter | RL | L | L |

| BE10 | Lack of operating the loading lever | L | L | L |

| BE11 | Defect in breaker valves | L | L | L |

| BE12 | Defect in tanker drain valve | L | L | L |

| BE13 | Forgetfulness of quality control operator in the process of laying | RL | RL | RL |

| BE14 | Inadequate equipment | VL | VL | VL |

3.2. Fault Tree Analysis (FTA)

The fault tree is a structure that shows all the causes of the main event. To build the fault tree, the events in the loading arm (primary, middle, and basic) were first identified. Then, communications were identified using logical symbols known as "AND" and "OR" gates. The "AND” is used when the outbound event of all input events is required, and the "OR” is used when at least one input event is sufficient (9). The FTA indicates the probability of failure of a system based on the failure rate of the basic events. The fault tree expresses the reliability of the system by providing a framework for qualitative and quantitative evaluation of the main event (10). The determination of minimum shear sets (MCSs) is performed in fault tree qualitative analysis. The shear set refers to a combination of basic events that occur in the main event. When the underlying events occur simultaneously, the main event will occur (11). In the quantitative model of the fault tree, the probabilities of occurrence of basic, intermediate, and major events and also shear sets were calculated using Equations 1 to 3.

Where, PAnd (E) is the probability of the intermediate or top event with AND input, POr (E) is the probability of the intermediate or top event with OR input, P (Ei) is the probability of occurrence of events in the fault tree, Ei represents the total number of input events for K = 1, 2, 3, etc., FP (BEi) indicates the probability of occurrence of each basic event, and P(MCSj) is the probability of occurrence of the minimum shear set. In addition, the importance measure (IM) of basic and intermediate events and minimum sets in the main event occurrence was calculated using Equations 4 and 5.

Where, P (TE) is the top event probability,

3.3. ETA

The event tree is a deductive method that simultaneously generates two branches, including successes and failures that show all the possible consequences of a critical risk occurrence. The purpose of the event tree is to determine the consequences of the initial event by considering protection systems (12). Event tree analysis is done in both quantitative and qualitative forms. In the qualitative analysis of the event tree, the consequences of the top event were determined. The likelihood of any event is also determined in the event tree simulation. Probability determination should be based on the operator's actions and the success or failure of the system to prevent the occurrence of a hazard (13). The occurrence probability of each consequence was calculated using the following equation:

Where, Pr (TE) is the probability of top event and Pr (E) is the probability of success or failure of the safety system to cause a major event.

3.4. Cause Consequence Model

Because the fault tree and event tree methods cannot directly describe the whole incident process, then, by combining the diagrams of the fault tree and the event tree and performing the related calculations, the Bow-tie diagram represents a graphical representation of the whole accident process has been achieved (5).

4. Results

In the present study, primarily risks were identified using experts' opinions. According to the results, the risk of the overflow of petroleum products was highest among the risks (Table 2). Therefore, product overflow can be considered as the top event of the fault tree. Then, using the expert opinion system, the basic events that were involved in the top event were identified and categorized, and the fault tree for the risk of a petroleum product flooding is shown in Figure 1. Besides, the probability of occurrence of basic, intermediate, and top events and minimum cut sets were calculated. Tables 2 and 3 show the probability of occurrence and the importance of basic, intermediate, and top events and minimum cut sets. Then, the probability of each outcome was calculated by determining the probability of failure or success of each of the protective layers (Table 4). Finally, by combining the fault tree and the event tree, the BTA structure is plotted (Figure 1).

Probability of Occurrence of Basic and Intermediate Events and Importance of the Events Considered In the Fault Tree

| Tag | Event | Probability of Occurrence (per Year) | Importance Measure | Ranking a |

|---|---|---|---|---|

| BE01 | Incorrect volume given to meter | 2.23 × 10-7 | 7.11 × 10-1 | 4 |

| BE02 | The volume recorded in the bill of lading does not fit the tanker type | 1.57 × 10-9 | 3.02 × 10-3 | 13 |

| BE03 | Adverse effects of environmental conditions | 4.49 × 10-8 | 7.13 × 10-1 | 6 |

| BE04 | Meter burnout due to over-operation | 1.87 × 10-8 | 5.15 × 10-1 | 10 |

| BE05 | Defect in the diaphragm valves | 3.15 × 10-8 | 3.16 × 10-1 | 9 |

| BE06 | Turning on the pumps simultaneously | 5.46 × 10-7 | 6.44 × 10-2 | 2 |

| BE07 | The meter is set incorrectly | 1.63 × 10-8 | 5.12 × 10-1 | 11 |

| BE08 | Defect in rotation of bearing | 4 × 10-8 | 1.44 × 10-1 | 8 |

| BE09 | Locking the handle of the meter | 4.48 × 10-8 | 1.44 × 10-1 | 7 |

| BE10 | Lack of operating the loading lever | 1.87 × 10-8 | 1.02 × 10-1 | 10 |

| BE11 | Defect in breaker valves | 3.15 × 10-8 | 8.93 × 10-1 | 9 |

| 12BE | Defect in tanker drain valve | 1.22 × 10-8 | 3.48 × 10-2 | 12 |

| BE13 | Forgetfulness of quality control operator in the process of laying | 4.49 × 10-8 | 9.14 × 10-1 | 6 |

| BE14 | Inadequate equipment | 8.16 × 10-11 | 3.52 × 10-2 | 14 |

| TE01 | Tank overflow | 3.12 × 10-7 | Top event | Top event |

| IE01 | The volume given to the meter exceeds the tank capacity | 2.24 × 10-7 | 7.16 × 10-1 | 3 |

| IE02 | Fault in filler system | 3.15 × 10-8 | 9.93 × 10-2 | 9 |

| IE03 | Previous product in tanker | 5.71 × 10-8 | 1.82 × 10-1 | 5 |

| IE04 | Malfunction in the automatic meter system | 3.15 × 10-8 | 9.93 × 10-2 | 9 |

| IE05 | Electrical defect of meter | 3.15 × 10-8 | 9.93 × 10-2 | 9 |

| IE06 | The meter current exceeds the allowed range | 5.62 × 10-7 | 1.92 × 10-2 | 1 |

| IE07 | Mechanical defect of meter | 1.79 × 10-15 | 3.20 × 10-3 | 15 |

| IE08 | Fault in manual system of meter | 3.89 × 10-16 | 8.33 × 10-2 | 16 |

The scenario of the overflow of oil from a tanker using bow tie analysis (BTA) diagram

Probability of Occurrence and Importance Measure of Minimum Cuts in Fault Tree

| Tag | Cut sets | Probability (per year) | Importance measure | Ranking a |

|---|---|---|---|---|

| CS01 | BE02, BE01 | 3.50 × 10-16 | 1.12 × 10-9 | 1 |

| CS02 | BE06, BE05, BE04, BE03 | 1.44 × 10-29 | 4.61 × 10-23 | 3 |

| CS03 | BE07, BE05, BE04, BE03 | 4.30 × 10-31 | 1.37 × 10-24 | 3 |

| CS04 | BE09, BE08 | 1.79 × 10-15 | 5.74 × 10-9 | 1 |

| CS05 | BE11, BE10 | 5.89 × 10-16 | 1.88 × 10-9 | 1 |

| CS06 | BE14, BE13, BE12 | 4.46 × 10-26 | 1.43 × 10-19 | 2 |

The Probability of the Eventual Consequences of the Event Tree

| Tags | Description | Probability |

|---|---|---|

| C1 | Explosion | 1.31 × 10-7 |

| C2 | Vapor Cloud Explosion (VCE) | 1.65 × 10-8 |

| C3 | Vapor Cloud Explosion (VCE) | 1.39 × 10-11 |

| C4 | Fire | 2.01 × 10-9 |

| C5 | Overflow | 7.76 × 10-7 |

5. Discussion

In this study, the risk assessment of loading arms was performed by the BTA technique. This method has been used in other studies (14). According to the results of the qualitative structure of the fault tree that is depicted in Figure 1, it can be said that 14 basic events and 8 intermediate events are involved in the overflow event. The probability and the degree of importance of each event are shown in Table 2. Among the basic events, turning on the pumps simultaneously with the probability of occurrence of 5.46 × 10-7, incorrect volume given to the meter with the probability of occurrence of 2.23 × 10-7, forgetfulness of quality control operator in the process of laying with the probability of occurrence of 4.49 × 10-8, and among intermediate events, fault in filler system, malfunction in the automatic meter system, and electrical defect of the meter with the same probability of 9.93 × 10-2 are most likely to cause an oil overflow. The probability of an overflow occurring from the tanker was calculated to be 3.12 × 10-7. These findings suggest that attention to the safety of the meter is very essential. The main events that can lead to the top event are related to the meter. This device plays an important role in the process of loading oil products on platforms. The findings also emphasized the importance of electrical safety and the role of human error. In places in which large amounts of fuel materials are kept, an electrical defect may result in many accidents, like fire and explosion. Another serious subject is human error. Many accidents are of human origin; for example, in this study, some events, such as the forgetfulness of the quality control operator in the process of laying was related to the reactions of operators. It seems that this subject is needed to be more studied.

Moreover, according to the findings of this study (Table 3), the top event can occur through different ways. This problem indicates that for avoiding the occurrence of the top event, it is needed to inhibit all paths that may lead to the event. Six minimum cut sets for 14 basic events a large number and emphasizes the necessity of implementing control measures.

According to Table 2, explosions and overflow are the most important consequences of the overflow event when the protective layers fail, which their probabilities of occurrences were calculated to be 1.31 × 10-7 and 7.76 ×10-8, respectively.

In the study by Mirzaei et al., 16 top events, 5 intermediate events, and 11 minimum cut sets were obtained in risk assessment of LPG gas tanks using the BTA technique, and the probability of the major event occurring was 3.45 × 10-2 (14).

van Thienen-Visser et al. conducted a risk assessment study for a gas oil storage in an abandoned salt cavern. They considered both the causes and consequences in their BTA. They showed that the major cause of accidents arising from subsurface storage is human error (15). This result is consistent with our study because one of the most important events that can lead to the major accident is human error. Similarly, it can be said that many unsafe conditions also are related to human acts. On the other hand, we have automatic processes in the oil and gas industries, which are associated with risks, as well. For example, Yu et al. conducted a study using BTA for underwater robots in offshore oil and gas operations. They suggested that collisions of autonomous underwater vehicles in offshore oil and gas operations may lead to some consequences, like loss of equipment, pipeline leak, and mission failure, and the bow-tie could analyze causes and consequences of major events (16).

5.1. Conclusion

In the present study, risk analysis was performed by the BTA technique for the arm section of oil rig loading platforms. BTA risk assessment is performed to trace the hazard event path from the phase of the hazard to the consequences of the hazard. In this technique, the events leading to the top event and the consequences of the top event were determined, and the probability of each was calculated. The importance of minimal incidents and cuts was also identified, which can be used to allocate resources and facilities to reduce the risk event and its consequences. The results of this study showed that the basic events of simultaneous switching on pumps, giving the wrong volume to the meter, and trapping the QC operator in the sedimentation operations are most likely to affect overflow. The results also showed that the use of control measures in the prevention of immediate and delayed sparks had the greatest impact on the prevention and control of spillover events.

References

-

1.

Zarei E, Azadeh A, Aliabadi MM, Mohammadfam I. Dynamic safety risk modeling of process systems using bayesian network. Process Saf Prog. 2017;36(4):399-407. https://doi.org/10.1002/prs.11889.

-

2.

Fuentes-Bargues JL, Gonzalez-Cruz MC, Gonzalez-Gaya C, Baixauli-Perez MP. Risk analysis of a fuel storage terminal using HAZOP and FTA. Int J Environ Res Public Health. 2017;14(7). [PubMed ID: 28665325]. [PubMed Central ID: PMC5551143]. https://doi.org/10.3390/ijerph14070705.

-

3.

Hou Z, Zhao P. Based on fuzzy bayesian network of oil wharf handling risk assessment. Math Probl Eng. 2016;2016:1-10. https://doi.org/10.1155/2016/6532691.

-

4.

Tixier J, Dusserre G, Salvi O, Gaston D. Review of 62 risk analysis methodologies of industrial plants. J Loss Prev Process Ind. 2002;15(4):291-303. https://doi.org/10.1016/s0950-4230(02)00008-6.

-

5.

Xu Q, Xu K. Mine safety assessment using gray relational analysis and bow tie model. PLoS One. 2018;13(3). e0193576. [PubMed ID: 29561875]. [PubMed Central ID: PMC5862416]. https://doi.org/10.1371/journal.pone.0193576.

-

6.

Ouache R, Ruparathna R, Sadiq R, Hewage K. Fire risk assessment model for residential buildings using bow-tie method. Vancouver, Canada: The University of British Columbia; 2018.

-

7.

Meland PH, Bernsmed K, Frøystad C, Li J, Sindre G. An experimental evaluation of bow-tie analysis for cybersecurity requirements. In: Katsikas SK, Cuppens F, Cuppens N, Lambrinoudakis C, Antón A, Gritzalis S, et al., editors. Computer Security. Netherland: Springer; 2019. p. 173-91.

-

8.

Khakzad N, Khan F, Amyotte P. Quantitative risk analysis of offshore drilling operations: A Bayesian approach. Saf Sci. 2013;57:108-17. https://doi.org/10.1016/j.ssci.2013.01.022.

-

9.

Zhang Y, Guan X. Selecting project risk preventive and protective strategies based on bow-tie analysis. J Manage Eng. 2018;34(3):4018009. https://doi.org/10.1061/(asce)me.1943-5479.0000603.

-

10.

Khare V, Nema S, Baredar P. Reliability analysis of hybrid renewable energy system by fault tree analysis. Energy & Environment. 2018;30(3):542-55. https://doi.org/10.1177/0958305x18802765.

-

11.

Mahmood YA, Ahmadi A, Verma AK, Srividya A, Kumar U. Fuzzy fault tree analysis: A review of concept and application. Int J Syst Assur Eng Manag. 2013;4(1):19-32. https://doi.org/10.1007/s13198-013-0145-x.

-

12.

Pontiggiaa M, Vairob T, Fabianob B. Risk assessment of buried natural gas pipelines. Critical aspects of event tree analysis. Chemical Engineering. 2019;77. https://doi.org/10.3303/CET1977103.

-

13.

Kim M, Wang J, Park C, Cho Y. Development of the risk assessment model for railway level-crossing accidents by using the ETA and FTA. J Korean Soc Railw. 2009;12(6):936-43.

-

14.

Mirzaei aliabadi M, Mohammad Fam I, Kalatpour O, Babayi mesdaraghi Y. [Risk assessment of liquefied petroleum gas (LPG) storage tanks in the process industries using the Bowtie technique]. J Occup Hyg Eng. 2016;3(2):1-11. Persian. https://doi.org/10.21859/johe-03021.

-

15.

van Thienen-Visser K, Hendriks D, Marsman A, Nepveu M, Groenenberg R, Wildenborg T, et al. Bow-tie risk assessment combining causes and effects applied to gas oil storage in an abandoned salt cavern. Eng Geol. 2014;168:149-66. https://doi.org/10.1016/j.enggeo.2013.11.002.

-

16.

Yu M, Venkidasalapathy JA, Shen Y, Quddus N, Mannan SM. Bow-tie analysis of underwater robots in offshore oil and gas operations. Offshore Technology Conference. Texas, USA. OnePetro; 2017.