1. Background

Lemon verbena (Lippia citriodora Kunth.), belonging to the family Verbenaceae, is a medicinal and aromatic shrub (1). This plant is native to Central and South America and is mainly cultivated in many countries for its medicinal and nutritional values (2). Traditionally, the leaves of lemon verbena are utilized as a remedy for the treatment of gastrointestinal and respiratory disorders and added to food as seasoning (3). The dried leaves of L. citriodora are also recommended for treating the digestive and nervous ailments (4). Essential oil is the main active ingredient in L. citriodora, which consists of a wide variety of constituents (5). The most important constituents of lemon verbena include geranial, neral, citral, 1,8-cineole, geraniol, linalool, and limonene (6).

Some medicinal herbs, such as lemon verbena, can be marketed in both fresh and dried forms. However, it is mainly utilized for the preparation of herbal tea. The moisture content of fresh herbs is usually 75% to 80% that should be reduced to less than 15% for subsequent processing (7). Drying is an important step in the processing of medicinal plants to decrease microbial contamination and growth, reduce packaging costs, decrease volume and weight of herbs for easier transportation and storage (8). Although the drying process reduces the plant moisture content and prevents the activities of fungi, bacteria, and yeasts, and enables long-term storage (9, 10), it may lower the herb quality because aromatic herbs and spices are sensitive to drying processes. In addition, thermal processing may transform the pro-health constituents of plants to inert or harmful substances through chemical reactions (11). Thus, drying in optimum conditions is a necessity for attaining a high-quality herbal product.

Recently, a variety of natural, artificial, and combined techniques has been used to dry medicinal herbs. Natural drying is a low-cost procedure but its duration is high. Moreover, some metabolites may be metabolized; thus, achieving a constant standard quality is not applicable (12). Microwave radiation is an alternative and novel approach for drying plants. This not only reduces the drying duration, but also preserves the color of dried plants and the herbal active ingredients (13, 14). The effectiveness of drying techniques mainly depends on the material texture and phytochemical structure. The method of drying may differ from a plant material to another. For example, essential oil of thyme (Thymus daenensis Celak.) was increased by oven-drying (8), but that of basil (Ocimum basilicum) was decreased by oven-drying (15). Torki-Harchegani et al. (16) stated that the leaves of peppermint dried by microwave radiation had less quantity of essential oil. However, the quality of basil was lower in microwave-drying than in shad and freeze-drying (15).

2. Objectives

The current study aimed to specify the effects of various drying methods on phytochemical characteristics of L. citriodora.

3. Methods

3.1. Plant Material

The aerial parts of lemon verbena (Lippia citriodora) were harvested from the research farm of Institute of Medicinal Plant, ACECR, located 55 km away from Tehran, Iran. The harvesting operation was carried out in the morning.

3.2. Drying Methods and Equipment

The drying process was based on a factorial experiment in a randomized complete block design with three replications. In terms of pre-drying operation, we applied two conditions: (1) plant samples were exposed to the sun for 3 hours for pre-drying and (2) no pre-drying operation was applied to samples but they were dried immediately after harvest using the given drying method. In terms of drying operation, there were various conditions including: no drying (freshly harvested plant sample), drying in shade, drying in the oven at 35, 45, and 55°C, and drying in the microwave oven at 100, 500, and 1000 W powers. In this study, the fresh sample and the dried sample in shade were used as controls. In the oven drying process, the plant material was spread on a tray in a thin layer and oven temperature was set at 35, 45, and 55°C. A microwave oven (2250 W power output, 2450 MHz; Samsung, Model MC35J8055CK) was used for drying plant samples. The drying process ended when the leaves moisture reached 10 percent.

3.3. Essential Oils (EO) Analysis

The dried samples were ground by a Moulinex food processor and passed through a 20-mesh sieve. Then, 50 g of the ground sample was dissolved in 1 L of distilled water in a 2-L flask to extract essential oils by the hydrodistillation method for 3 hours using the Clevenger apparatus, following European Pharmacopoeia guidelines. The essential oils were dried over anhydrous sodium sulfate and kept at 4°C until analysis. The EO Extractionwas repeated three times and the mean values were reported as EO percentage in the dried plant.

The GC-MS analysis was conducted using an Agilent instrument coupled with a 5973 Mass system equipped with a flame ionization detector (FID) and a BPX5 capillary column (30 m × 0.25 mm; 0.25-μm film thicknesses). The following temperature program was used for the oven: increasing temperature at 60°C, holding for 2 minutes, gradual increasing to 150°C at the rate of 3°C min-1, increasing temperature to 270°C at 5°C min-1, and holding for 15 minutes. The carrier gas was He with a flow rate of 1.1 mL min-1; injector and detector temperatures were 300°C and the split ratio was 1:50. Mass spectra were reserved at 70 eV. The essential oil constituents were identified by comparing the mass spectra and their retention indices with those published in the literature (17) and presented in the MS computer library (17).

3.4. Statistical Analysis

The data were analyzed using analysis of variance in SAS software (version 9.1). The mean values were compared using Duncan’s multiple range test at 5% confidence interval.

4. Results

4.1. Effect of Drying Method on the Essential Oil Content

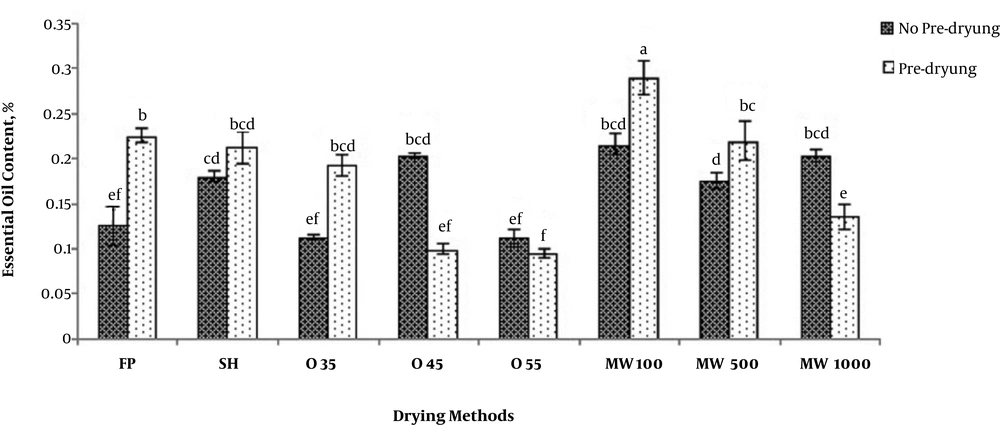

The results indicated that the content of essential oil (EO) was significantly affected by the method of drying (Table 1). According to Figure 1, the EO content was enhanced in oven-drying at 35°C, microwave-drying at 100 W and shade - drying with pre - drying operation.. This study showed that the essential oil content of L. citriodora was decreased by raising the temperature in vacuum oven-drying andoven drying with the pre-drying process. The highest EO content was obtained by microwave-drying at 100 W with a pre-drying condition. In addition, the lowest amount of EO was related to oven-drying at 55°C.

| S.O.V | df | Mean of Square | MH | OM | SH | OS | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Essential Oil | Limonene | 1,8-Cineole | Neral | Geranial | Curcumene | Spathulenol | Caryophyllene Oxide | ||||||

| R | 2 | 0.0003ns | 3.72a | 1.61a | 3.76ns | 1.51ns | 2.48a | 0.98b | 0.04ns | 3.84a | 36.9a | 1.1ns | 0.039ns |

| P | 1 | 0.003a | 0.136ns | 1.54b | 5.90ns | 1.50ns | 1.68a | 10.3a | 2.27b | 0.018ns | 30.7b | 24.1a | 18.2a |

| D | 7 | 0.011a | 17.16a | 3.68a | 43.08a | 77.25a | 1.20a | 3.14a | 1.52a | 34.5a | 149.1a | 36.3a | 15.9a |

| P × D | 7 | 0.008a | 3.44a | 0.51ns | 8.03a | 15.5a | 0.83a | 6.64a | 4.24a | 3.18a | 20.4a | 8.31a | 25.7a |

| Error | 30 | 0.0004 | 0.48 | 0.25 | 1.75 | 3.33 | 0.14 | 0.26 | 0.42 | 0.69 | 5.9 | 0.76 | 0.77 |

| CV | 12.3 | 5.83 | 8.11 | 7.96 | 7.95 | 6.91 | 11.7 | 10.9 | 5.59 | 5.03 | 11.2 | 6.79 | |

Abbreviations: CV, coefficient of variation; D, drying methods; df: degree of freedom; MH, monoterpene hydrocarbon; ns, no significant difference; OM, oxygenated monoterpenes; OS, oxygenated sesquiterpenes; P, Pre-drying; R, replicate; SH, sesquiterpene hydrocarbon; S.O.V, source of variation.

aSignificant at P ≤ 0.01.

bSignificant at P ≤ 0.05.

The comparison of mean changes in the essential oil content by different drying methods in both pre-drying conditions. FP: fresh plant; SH: shade drying; O 35, 45, and 55: oven-drying at 35, 45, and 55°C, respectively; MW 100, 500, and 1000: microwave drying at 100, 500, and 1000 W, respectively.

4.2. Effect of Drying Methods on the Essential Oil Constituents

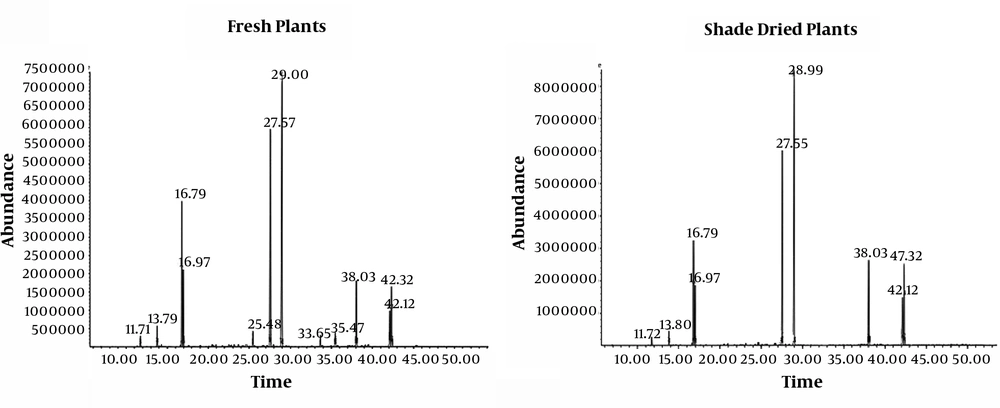

The drying methods had significant effects on EO components (Table 1). In our study, seven main constituents were determined in the dried and fresh samples of L. citriodora. GC-FID chromatograms of essential oils from fresh and shade-dried samples are shown in Figure 2. The oxygenated monoterpenes including 1,8-cineole, neral, and geranial were the main components of L. citriodora essential oil (Table 2). In pre-drying and no pre-drying conditions, the highest 1,8-cineole content was obtained in oven-drying at 45°C (7.59% and 7.67%, respectively). However, 1,8-cineole content had no significant difference between oven-drying at 45°C and microwave-drying at 500 W. In addition, the lowest amount of 1,8-cineole (4.94%) was related to oven-drying at 55°C without pre-drying (Table 2). Neral and geranial contents were decreased by drying conditions and their greatest values were achieved in fresh plant samples followed by shade-dried samples (Table 2). In this study, the content of the main monoterpene hydrocarbon (Limonene) was more in microwave-drying (especially at 1000 W) at both pre-drying and no pre-drying conditions than in other drying methods (Table 2). In addition, the highest (6.52%) and the lowest (4.35%) contents of curcumene as a sesquiterpene hydrocarbon were obtained by shade-drying without pre-drying and oven-drying at 45°C after pre-drying, respectively (Table 2). Without the pre-drying operation, the various methods of drying led to a decreased amount of oxygenated monoterpenes. However, spathulenol and caryophyllene oxide as two important oxygenated sesquiterpenes in L. citriodora oil were significantly affected by drying methods (Table 1). The maximum contents of spathulenol (6.99%) and caryophyllene oxide (8.41%) were related to treatment with oven-drying at 35°C without the pre-drying operation, and their minimum contents were achieved in oven-drying at 35°C with the pre-drying operation.

| Pre-Drying | Drying Methods | Limonene | 1.8-Cineole | Neral | Geranial | Curcumene | Spathulenol | Caryophyllene Oxide | MH | OM | SH | OS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No exposure to the sun before drying | Fresh plant | 11.2EF | 5.66CDEF | 20.03A | 27.3A | 5.10DE | 3.80EF | 5.2DEF | 14.8BC | 56.7A | 8.56CD | 11.7C |

| Shade | 10.7FG | 6.03BCDE | 19.4A | 26.2AB | 6.52A | 4.33CDE | 5.53CDE | 13.1D | 51.5B | 5.09E | 12.8C | |

| Oven 35 °C | 9.8GH | 6.90AB | 12.4F | 18.04G | 6.2AB | 6.99A | 8.41A | 12.4D | 42.0E | 11.06A | 19.4A | |

| Oven 45 °C | 12.5CD | 7.59A | 14.3DEF | 20.1EFG | 5.18CDE | 5.76B | 6.87B | 12.5D | 42.1E | 5.18E | 12.6C | |

| Oven 55 °C | 9.3H | 4.94F | 17.5ABC | 23.7BCD | 5.85ABC | 5.75B | 6.68BC | 12.2DE | 49.7BCD | 9.89ABCD | 16.4B | |

| MW 100 W | 13.9AB | 6.47BCD | 17.7ABC | 23.7BCD | 5.14CDE | 4.33CDE | 5.86BCDE | 17.6A | 51.0BC | 8.71CD | 12.9C | |

| MW 500 W | 13.5ABC | 6.92AB | 18.4AB | 24.5ABCD | 5.06DE | 3.99DEF | 5.02EF | 17.3A | 53.1AB | 8.89CD | 11.3C | |

| MW 1000 W | 14.8A | 6.5BC | 15.6CDE | 21.3EFG | 5.91AB | 3.62EF | 5.86BCDE | 18.4A | 46.4CD | 10.2ABC | 11.3C | |

| Exposer to the sun before drying | Fresh plant | 11.06EFG | 5.26EF | 19.5A | 26.7AB | 5.68BCD | 3.95DEF | 5.45CDE | 13.7CD | 51.7B | 2.4F | 12.2C |

| Shade | 11.06EFG | 5.26EF | 19.5A | 26.7AB | 5.68BCD | 3.95DEF | 5.45CDE | 13.7CD | 51.7B | 2.40F | 12.2C | |

| Oven 35 °C | 12.2DE | 5.98BCDE | 15.9CDE | 21.6DEF | 4.75EF | 0.99G | 4.21F | 15.3B | 46.4D | 8.33D | 8.6D | |

| Oven 45 °C | 9.8GH | 7.67A | 10.1G | 13.9H | 4.35F | 5.23BC | 6.36BCD | 10.9E | 37.6F | 5.73E | 11.5C | |

| Oven 55 °C | 9.96FGH | 5.67CDEF | 16.7BCD | 26.4AB | 6.19AB | 5.02BC | 6.67BC | 13.02D | 50.2BCD | 10.5AB | 16.4B | |

| MW 100 W | 13.15BCD | 5.58DEF | 18.5AB | 25.5ABC | 5.2CDE | 3.96DEF | 5.42CDE | 16.9A | 52.4B | 8.98BCD | 11.4C | |

| MW 500 W | 14.05AB | 6.92AB | 16.1BCD | 22.4CDE | 5.1CDE | 4.80CD | 6.67BC | 17.7A | 48.6BCD | 8.78CD | 14.9B | |

| MW 1000 W | 13.8ABC | 5.88CDEF | 13.5EF | 18.7FG | 5.01DE | 3.24F | 5.68BCDE | 17.4A | 41.2EF | 9.04BCD | 11.3C |

Abbreviations: MH, monoterpene hydrocarbon; MW, microwave; OM, oxygenated monoterpenes; OS, oxygenated sesquiterpenes; SH, sesquiterpene hydrocarbon.

aValues are expressed as percentage.

bThe values with the same letters in each column indicate no significant difference between treatments at the 5% level of probability.

According to our results, pre-drying significantly changed the components in oven-drying. The sesquiterpene hydrocarbons content was reduced with increasing oven temperature without pre-drying operation, but it was reversely related to temperatures of the oven after pre-drying. Although there was no change in the content of oxygenated sesquiterpene with increasing the temperature of the oven from 35 to 55°C without the pre-drying process, their contents were increased by increasing oven temperature after the pre-drying operation. The content of oxygenated monoterpene without pre-drying was increased by increasing the temperature in oven-drying (Table 2). The essential oil content was reduced with increasing the microwave radiation power in pre-drying conditions. The main components of L. citriodora essential oil were differentially changed by microwave powers. Neral, 1,8-cineole, and geranial contents were increased with the increment of microwave power up to 500 W, and then commenced to reduce without pre-drying operation. Indeed, the spathulenol content was decreased by rising microwave power in this group. In the pre-drying group, the contents of limonene, 1,8-cineole, spathulenol, and caryophyllene oxide were increased by the increment of microwave power from 100 to 500 W. Moreover, the percentages of some components such as neral, geranial, and curcumene were decreased by increasing the microwave power.

5. Discussion

Our findings showed that the EO content was significantly affected by the pre-drying operation, drying methods, and their interaction. In the pre-drying condition, the EO content was decreased by increasing microwave power and/or oven temperature, and the highest EO content was related to microwave-drying at 100 W with the pre-drying operation. It seems that the unfavorable effect of high microwave power and/or oven temperature could be related to the volatility and thermal degradation of essential oils and their oxidative processes during drying operation of plant materials. In addition, some reports indicated that high temperature in the drying process can damage glandular trichomes of medicinal herbs (7). Glandular trichomes are secretory structures responsible for the synthesis and accumulation of essential plant oils (18). In addition, increasing temperature causes further damage to the cell wall and plasma membrane and may affect plasma membrane permeability (19). These results are in line with the results of Ayyobi et al. (20) on peppermint and dill, Hamrouni-Sellami et al. (21) on Salvia officinalis L., and Dehghani Mashkani et al. (8) on Thymus daenensis Celak.

According to our results, the highest amount of limonene, the most important monoterpene hydrocarbon, was obtained by microwave-drying in both pre-drying and no pre-drying conditions. Although oxygenated monoterpenes including neral and geranial were reduced by different drying methods, the highest content of 1,8-cineol was obtained by oven-drying at 45°C. The greatest amount of sesquiterpene hydrocarbon was attained by drying with an oven at 35°C with no pre-drying condition. The highest content of curcumene, as the main sesquiterpene hydrocarbon, was related to shade-drying without pre-drying condition. The highest content of oxygenated sesquiterpene and its main components including spathulenol and caryophyllene oxide was obtained by oven-drying at 35°C without pre-drying operation whereas their lower amounts were obtained by oven-drying with the pre-drying operation. The literature shows that EO compounds differentially respond to drying methods and temperatures (8, 18). Dehghani Mashkani (8) reported that the main monoterpene hydrocarbons including α-thujene, myrcene, α and γ-terpinene, α-pinene, para-cymene, and 1,8-cineole were decreased by various drying methods without pre-drying. Since monoterpenes are accumulated in outer cells at high temperatures, some low-molecular-weight monoterpenes are removed faster than terpenoides (22). Drying temperatures used in hot-air drying may transform some of the original volatile oils of lemon verbena into new chemicals, indicating that these constituents are more sensitive to hot-air drying (3). Microwave radiation reduces drying duration without increasing the temperature at the material surface (23). Hence, EO sensitive components could be maintained during the drying process. Similar results were also reported by Rahimmalek and Goli (24) and Ghasemi Pirbalouti et al. (15).

5.1. Conclusions

The results showed that the pre-drying process and various methods of drying had significant effects on the content and constituents of essential oil of Lippia citriodora Kunth. The maximum content of essential oil was acquired by microwave-drying at 100 W following the pre-drying operation. The highest amounts of monoterpenes including monoterpene hydrocarbons and oxygenated monoterpenes were related to microwave-dried samples and fresh plant samples, respectively. The maximum amounts of sesquiterpenes including sesquiterpene hydrocarbons and oxygenated sesquiterpenes were achieved in drying by oven at 35°C without pre-drying. In general, microwave drying at 100 W with pre-drying was the best method for drying Lippia citriodora to obtain the highest essential oil quantity and quality.