1. Background

The water crisis in various parts of the world makes it compulsory to manage water supplies. One of the most important ways to manage water resources is wastewater reuse. Therefore, the treatment and reuse of residential greywater should be taken into consideration. Greywater is low-contaminant wastewater and includes wastewater produced by showers, washing machines, bathtubs, and handwashing basins, but not toilet wastewater (1, 2). Although greywater accounts for a large volume of municipal wastewater (40 to 80%) (2), it only contains 30% of the organic part and 9 to 20% of nutrients in the municipal wastewater (3). The advantages of greywater separation include reducing the cost of collecting mixed wastewater, eliminating the need to build large treatment plants, increasing wastewater reuse, compensating for water shortages, and using the nutrients in greywater for agricultural and horticultural uses to diminish the usage of chemical fertilizers.

Greywater can be used for non-drinking purposes to reduce water stress (4). The average annual rainfall in Iran, about 250 mm, is inadequate and about one-third of the world's annual rainfall average. The distribution of precipitation varies from 100 mm in the east to 2000 mm in the north of the country, resulting in diverse climates (5). In recent years, the reuse of municipal wastewater treatment plant effluents for water management has become common in some parts of Iran. However, the treatment and reuse of greywater have rarely been investigated. Previous studies have applied various physical, chemical, biological, or combination techniques to treat greywater in different countries. New approaches, such as photocatalytic oxidation processes, have also been used to treat greywater (6).

In our study, the simultaneous treatment of synthetic greywater (at low, medium, and high organic load) and real greywater (RGW) by the combined process of ozonation/ (GAC)/ultrafiltration (UF) was investigated. Furthermore, the efficiency of the treatment system in removing pollutants was compared with Iranian effluent standards for discharge to absorbing wells, surface water, and agricultural and irrigation usage. In this method, the treatment of greywater is mainly physical and, to some extent, biological. In addition, we utilized the ozonation process as a chemical treatment method. Ozonation unit (O3) is used as an advanced oxidation method to remove trace organic matter, and in terms of economic analysis, ozone is one of the least expensive advanced treatment techniques (7). Furthermore, the cost of electricity in Iran is low because of government subsidies to private power plants. As a result, the usage of ozone is justified financially (8).

2. Objectives

This study aimed to select a method for greywater treatment that is effective, new, environment-friendly, and cost-effective. This is the first report of using integrated ozone, GAC, and UF system for synthetic and RGW treatment for a long time (6 months).

3. Methods

3.1. Synthetic Greywater Production

Necessary chemicals, such as boric acid (99.9% purity, Merck), glucose (99% purity, Merck), Na2HPO4 (≥ 99% purity, DNAbiotech), Na2SO4 (≥ 99% purity, Merck), NaHCO3 (≥ 99% purity, Merck), was used to prepare greywater. Based on previous studies, chemicals and commercial compounds were used to prepare synthetic greywater at low concentrations (COD ≈ 200), according to Table 1. The greywater formula was concentrated for preparing synthetic greywater in medium and high concentrations.

| Chemical Substance Amount per Liter | Amount per Liter | Commercial Products | Amount per Liter |

|---|---|---|---|

| Secondary effluent | 20 mL | Deodorant | 10 mg |

| H3BO3 | 1.4 mg | Shampoo | 720 mg |

| C6H12O6 | 28 mg | Laundry effluent | 150 mg |

| Na2HPO4 | 39 mg | Sunscreen or moisturizer | 10 - 15 mg |

| Na2SO4 | 35 mg | Toothpaste | 32.5 mg |

| NaHCO3 | 25 mg | Vegetable oil | 7 mg |

| Clay (Unimin) | 50 mg |

3.2. Design of a Pilot of O3/GAC/UF Combined Process

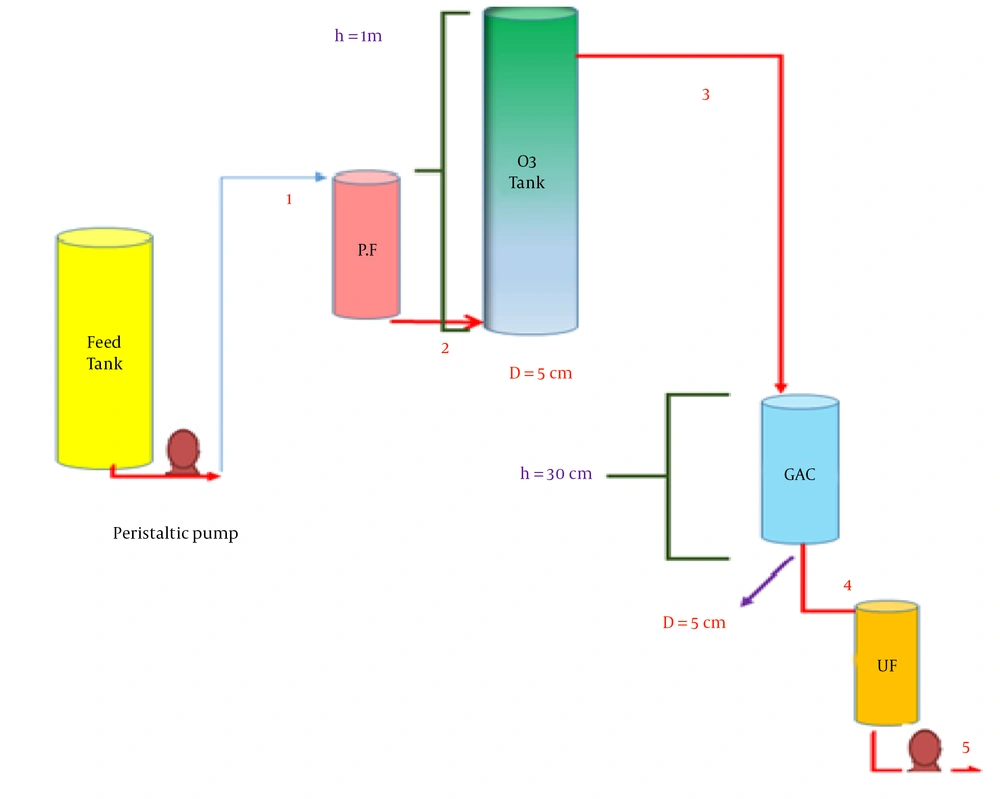

At first, the research pilot included a feed tank with a volume of 500 liters, pre-filtration with a cartridge filter (pore size: 5 µ), ozonation reactor (dose: 5 mg/L), GAC reactor, and UF unit. Figure 1 shows the schematic of the pilot.

3.3. Preparation and Transfer of Carbon Grains to GAC Reactor

The GAC was purchased from Kimiya Carbon Markazi Company, Arak, Iran. The characteristics of granules are given in Table 2. The properties of the UF membrane are listed in Table 3.

| Characteristic | Values | Test Method |

|---|---|---|

| Iodine number (mg/g) | 980 | ASTM |

| Moisture (% bwt) | Max1 | ASTM |

| Total ash% | < 5 | ASTM |

| Surface area (m2/g) | 950 | ASTM |

| pH | 7.5 | ASTM |

| Hardness number | 94 | ASTM 4058 |

| Surface area (m2/g) | 909 | BET |

| Material | Polypropylene |

|---|---|

| Type | Hollow fiber |

| Capillary thickness (µm) | 40 ~ 50 |

| Capillary outer diameter (µm) | 450 |

| Capillary pore diameter (µm) | 0.01 ~ 0.2 |

| Ventilation rate (cm3/cm2.s) | 7 × 10-2 |

| Porosity (%) | 40 ~ 50 |

| Lengthways strength (KPa) | 120,000 |

| Designed flux (L/M2/H) | 6 ~ 9 |

| Area of the membrane module (m2/module) | 0.1 |

| Operating pressure (MPa) | -0.01 ~ -0.03 |

| Abnormal pressure (KPa) | > -0.05 |

The following steps were taken to prepare GAC before transferring to the GAC reactor:

(1) Activated carbon grains were sieved, and granules smaller than 2 mm in diameter (mesh 10) and larger than 1.19 mm (mesh 16) were selected for transfer to the GAC reactor.

(2) Activated carbon grains were washed with distilled water and were dried at 104°C for 2 h.

(3) Two laser-cut circular plates were perforated for equal distribution of wastewater flow at the top and bottom of the GAC reactor.

(4) A layer of coarse sand was used to prevent the possible escape of activated carbon grains on the reactor floor.

(5) The GAC reactor was filled with activated carbon grains.

3.4. Operation of Greywater Treatment System (O3/GAC/UF)

The continuous flow of synthetic greywater entered the treatment system at a low organic loading rate of 6.1, medium of 12.2, and high of 18.3 gCOD/L.d for six months. Afterwards, RGW samples taken from a residential complex in Shiraz, Iran, entered the treatment system for two weeks. The empty bed contact time of the GAC reactor was 50 min. The GAC and UF units were backwashed every two weeks.

3.5. Chemical Analysis

The COD was measured using the closed reflux method (5220-D, colorimetric method, Spectrophotometer, Hach Company, DR5000), and the five-day biochemical oxygen demand (BOD5) was determined using standard dilution water (5210-B). The LAS was measured by methylene blue active substance (MBAS) 5540–C method according to Standard Methods for the Examination of Water and Wastewater, 23rd edition (10). Turbidity was measured by turbidimeter (Hach, 2100Q), and pH was assessed by pH meter (metrhom, 827).

3.6. Data Analysis

In this study, mean, standard deviation and analysis of variance (ANOVA) were used to statistically compare the removal efficiency of parameters, including COD, BOD5, turbidity, and LAS at different organic loads. All the experiments in this study were completed in duplicates.

4. Results

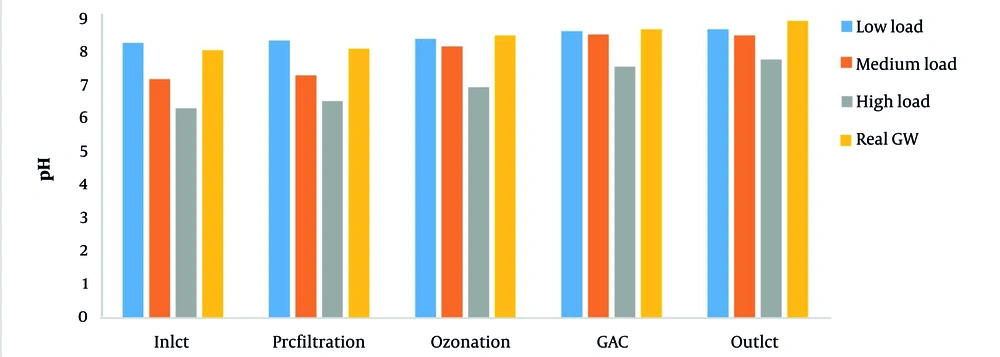

In previous studies, pH was usually between 5 and 9, depending on the types and the sources of greywater (11). In the present study, as Figure 2 shows, by increasing the amount of organic load in inlet synthetic greywater, the average pH decreases from 7.65 at low organic load to 5.84 at high organic load. In RGW, the average pH was in the neutral range. At the outlet of the treatment system, pH was neutral to slightly alkaline. However, the average pH in this study was confirmed by other investigations.

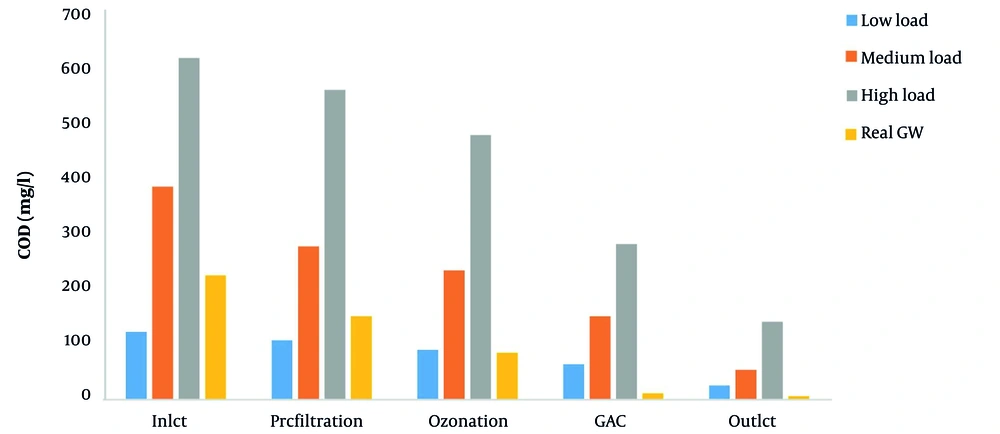

Figure 3 shows the average concentration of COD at low, medium, and high synthetic greywater and RGW in the treatment process. Figure 3 illustrates that, in synthetic greywater, the concentration of COD in the treatment system outlet rises by increasing the organic load. Furthermore, the elimination of COD in low, medium, and high organic loads of synthetic greywater was approximately 79.3%, 86.1%, and 77.3%, respectively, and the highest COD removal was achieved in medium organic load. The efficiency of the treatment process in removing COD from RGW was better than in synthetic greywater, and the average COD removal was up to 97.3%.

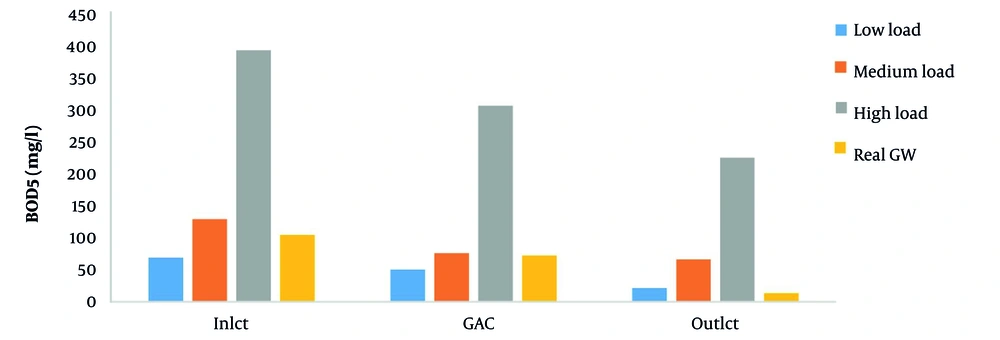

Figure 4 shows the average concentration of BOD5 in low, medium, and high organic loads of synthetic greywater and RGW in the treatment process. As shown, by increasing the organic loading rate in synthetic greywater, the concentration of outlet BOD5 also augments. The average BOD5 removal in low, medium, and high organic loads of synthetic greywater was approximately 69.6%, 48.9%, and 42.7%, respectively.

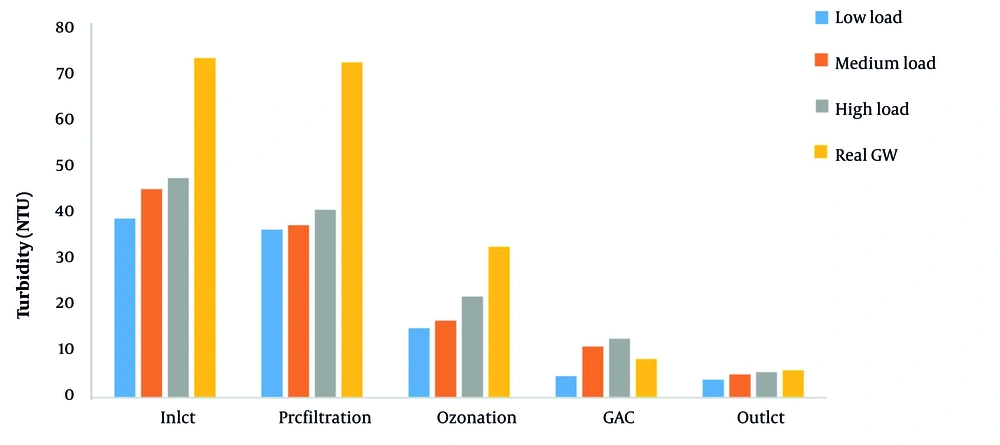

Figure 5 shows the average turbidity of the low, medium, and high organic loads of synthetic greywater and RGW in the treatment process. The turbidity removal in low, medium, and high organic synthetic greywater and RGW was 95.6%, 98.3%, 97.4%, and 97.9%, respectively.

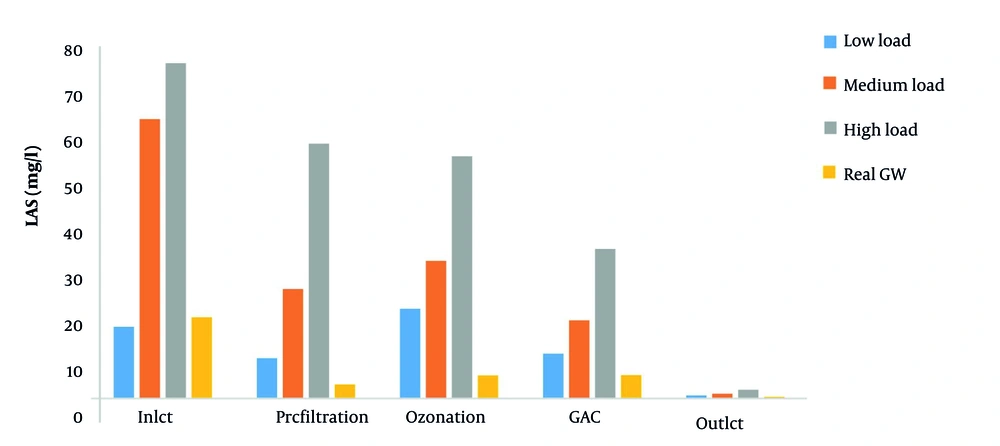

Figure 6 presents the average concentration of LAS in low, medium, and high organic loads of synthetic greywater and RGW in the treatment process. The LAS removal in low, medium, and high organic load synthetic greywater and RGW was 90.1%, 88.9%, 88.3%, and 91.9%, respectively.

5. Discussion

The results of ANOVA revealed that COD removal, except between low and high organic loads of synthetic greywater, was significantly different. According to the Iranian standard (Table 4), in low and medium organic load synthetic greywater and RGW, there were no restrictions on discharging effluent to absorbing wells and surface water, as well as agricultural and irrigation applications. At a high organic load synthetic greywater, the effluent can only be utilized for agricultural and irrigation purposes. ANOVA demonstrated that BOD5 removal in various loads of synthetic greywater and RGW was statistically significant (P < 0.05). The efficiency of the O3/GAC/UF combination system for BOD5 removal in RGW was almost 87%, which was higher than the synthetic types due to the difference in the initial composition of RGW. Another reason could be that BOD5 in RGW is more suspended than dissolved. Consequently, by eliminating SS by ultrafiltration, the percent of BOD5 removal from RGW increased compared to the synthetic types. In general, the lower removal of BOD5 might result from the limited role of biological treatment in this treatment system.

| Pollutant | Surface Water | Discharge to Absorbing Well | Agriculture & Irrigation |

|---|---|---|---|

| pH | 6.5 - 8.5 | 5 - 9 | 6 - 8.5 |

| COD (mg/L) | 60 (instantaneous: 100) | 60 (instantaneous: 100) | 200 |

| BOD5 (mg/L) | 30 (instantaneous: 50) | 30 (instantaneous: 50) | 100 |

| Turbidity (NTU) | 50 | ----- | 50 |

| LAS (mg/L) | 1.5 | 1.5 | 1.5 |

Moreover, ANOVA showed that the difference in turbidity removal between low load and other conditions (synthetic greywater with medium load and high load and RGW) was statistically significant. At the same time, it was not significant at other levels. With an increase in the organic load and turbidity, turbidity removal also rises because of the collision of particles with each other and through a porous bed in UF. This treatment system can impressively remove turbidity from greywater, and according to the standard of Iran effluent, this treatment system has no restrictions on low, medium, and high organic loads synthetic greywater and RGW for discharge effluent to absorbing wells and surface waters, as well as agricultural and irrigation usages. Furthermore, this treatment system can meet EPA standards for unlimited effluent usage (below 2 NTU). The average turbidity of the effluent at low, medium, and high organic loads synthetic greywater and RGW in this treatment system was 0.21, 0.23, 0.3, and 0.32 NTU, respectively.

The findings of ANOVA indicated that except for high organic loads synthetic greywater and RGW, the LAS removal is similar to other treatment systems, and it can effectively remove LAS from greywater. According to the Iranian standard, the effluent of this treatment system has no restrictions on low, medium, and high organic loads synthetic greywater and RGW to be discharged to absorbing wells, surface water, and agricultural purpose. In a study conducted in a residential complex, a physicochemical greywater treatment process consisting of coagulation, sedimentation, sand filter, and GAC was employed. In the mentioned study, the percent of turbidity, COD, and surfactant removal were 90%, 60%, and 80%, respectively (13), which were much higher than our study.

A research used a combined process of gravel, sand, activated carbon, cotton, and calcium hypochlorite for treating greywater from three different sources. In the mentioned study, the turbidity removal rate was reported at 88% (14). The results showed that despite the fewer number of treatment units, the efficiency of our study treatment system for removing turbidity from RGW and various synthetic greywater was higher because turbidity removal in low, medium, and high organic synthetic greywater and RGW was 95.6%, 98.3%, 97.4%, and 97.9%, respectively. The greywater collected from a camp facility service building in Egypt was treated by a membrane bioreactor (MBR), which removed 95% anionic surfactants and less than 80% of COD (15). Although MBR has been better at removing anionic surfactants, our study treatment system has a higher capacity for removing COD, especially from RGW.

In another study, a three-stage process involving an up-flow anaerobic biofilm reactor, followed by an up-flow aerobic reactor and vertical greenery system, was used to treat the RGW of a household (16). The results showed that the above treatment system removed about 93% of COD, 98% turbidity, and 92% of anionic surfactants. Turbidity and anionic surfactant removal were almost similar to the current investigation. However, our study treatment system has a remarkable ability to remove COD from RGW. Furthermore, our study treatment system benefits from easy maintenance in a physicochemical process, a sand filter with flotation and sedimentation was used to treat university complex greywater. The results showed that the removal efficiency of turbidity, COD, and BOD was 92%, 65%, and 57%, respectively. In our study, removing these pollutants from greywater (synthetic and real) was much higher than in the mentioned study (17).

In a dormitory complex in Iran, an advanced oxidation process (electrocoagulation with ozonation) was employed to remove COD, which achieved 85% COD removal. In comparison, the COD removal efficiency of our study system for medium organic load greywater (86%) and RGW (97%) was higher (18). A combined UV/ozone/biological aerating filter (BAF) process was also used as an advanced oxidation method to remove COD from the secondary effluent of the wastewater treatment plant. This system removed 61% of COD, while the efficiency of our study treatment system in removing COD at various loads of synthetic and RGW was higher than this system (19).

Although membrane processes are expensive, the operating costs mitigate when the membrane operates under the gravity-driven circumstance. Moreover, an increase in the amount of greywater in a shared greywater treatment plant may reduce the total cost due to the following: (1) reduction ratio of sharing to the total cost of the membrane treatment process by increasing the treatment capacity and (2) physical limitations of small operation units with low energy consumption which consume more energy than the actual need. Therefore, due to the increasing demand for improving the quality of greywater, developing new membrane materials, and reducing the price of membranes, we can hope for more sustainable and environment-friendly potentials of membrane-based processes for greywater treatment (20). In addition, the operational costs of GAC, which play a vital role in the treatment process of the present study, are very low, and it is approximately 28% of membrane processes (20).

5.1. Conclusions

This study investigates the treatment of synthetic greywater (at low, medium, and high organic load) and RGW by the combined ozonation/GAC/UF. Our results showed the average COD removal in low, medium, and high organic loads synthetic greywater and RGW as about 79%, 86%, 77%, and 97%, respectively. Furthermore, average BOD5 removal was approximately 69%, 49%, 43%, and 87%, respectively. Mean turbidity removal was about 95.6%, 98.3%, 97.4%, and 97.9%, respectively. The average LAS removal was found as about 90%, 88.9%, 88.3%, and 91.9%, respectively. The efficiency of the treatment system in removing pollutants was compared with Iranian effluent standards for discharge to absorbing wells and surface water, as well as agricultural and irrigation usages. The results showed that our treatment system has a good capability, especially for RGW treatment. According to the results of the present study, our treatment system was effective in treating greywater at different organic loads. Moreover, its ability to treat RGW (a residential complex in Shiraz) was more than synthetic greywater. We recommend this method as an effective method for greywater treatment, and it is a relatively low-cost and environment-friendly technique, especially in countries with conditions similar to Iran.