1. Background

Musculoskeletal disorders are a prevalent issue in industries, particularly in industrial machining (1, 2), and they account for a significant proportion of disabilities (3). Various factors contribute to these disorders. Excessive force, improper body posture, repetitive activities, vibration, and psychosocial factors are identified as major risk factors (4). Assessing exposure to work-related musculoskeletal disorders (WMSDs) is crucial for protecting workers in industries from the increasing prevalence of WMSDs (5).

There are various tools and methods to assess the risk of musculoskeletal injuries, each considering different factors for their assessments. For example, load weight is significant in manual material handling (MMH) methods, while the degree of body deviation from a neutral posture is critical in body posture assessment methods (6). When selecting ergonomic assessment methods and tools, practitioners must consider several aspects, including the objectives of the assessment, the level of detail assessed, available resources, and the applicability of the assessment program (7). Once risk factors are identified, practitioners may employ multiple similar assessment methods to achieve more accurate results. This approach facilitates risk prioritization and a more precise identification of the factors influencing risk (7, 8). These methods include self-reports, observation, and direct measurements. While direct methods offer considerable accuracy, observational methods are more commonly used (9).

The applicability of methods and tools varies, and no single method can comprehensively apply to all work situations. Industrial activities are typically complex, and assessing these activities necessitates the use of appropriate tools and methods. Although these evaluation methods have been previously studied, there remains a need for further investigation (10) by comparing their outcomes (11).

Ergonomic methods include the quick exposure check (QEC) (12) and the rapid entire body assessment (REBA) (13) to assess risks across the whole body, the rapid upper limb assessment (RULA) (14) for the upper limbs, and the strain index (15) for the distal upper extremities. Manual handling assessment charts (MAC) (16) liberty mutual manual materials handling tables (Snook tables) (17), the National Institute for Occupational Safety and Health (NIOSH) lifting equation (18), the Washington Industrial Safety and Health Act (WISHA) (19, 20), the key indicator method for pulling and pushing (KIM-PP), and the key indicator method for lifting, holding, and carrying (KIM-LHC) (21) are utilized to assess the risk of injury during MMH activities. In all these tools, intensity is considered, but some do not account for duration and frequency, which are critical in assessing occupational exposure (22). These methods, based on observational techniques, offer practical advantages such as being low-cost, easy to learn, user-friendly, and applicable in various work environments. Body posture and tasks are often determined using photographic techniques (23-25). These are among the most widely used methods (6) in industries. However, if an inappropriate method is used to assess the risk factor of musculoskeletal disorders, it may yield varying results and risk levels (26). Ergonomic methods have been developed with different objectives and vary in the area of the body evaluated or in the risk factors examined (27).

In recent years, the use of digital human models in industries has increased when applying ergonomic methods (28). Biomechanical tools can estimate the loads exerted on body joints and muscles, providing quantitative results to users (29, 30). The University of Michigan’s 3D static strength prediction programTM (3DSSPP) (31) and JACK SIEMENS (32) software are capable of estimating spine loads. These tools typically utilize body mass and joint locations as inputs to calculate intervertebral disc loads (33). The hand-calculation back compressive force (HCBCF) equation estimates lumbosacral (L5-S1) compression load in MMH tasks (34). Researchers have linked occupational back pain to fatigue failure in lumbar vertebrae, leading to the development of the lifting fatigue failure tool to predict cumulative loads in the lumbar area (35). Additionally, the survival chance tool (36) offers a suitable measure of cumulative spinal compression loading. Examining workplace conditions is one of the primary advantages of biomechanical risk assessment tools (37), which can significantly reduce musculoskeletal disorders (38). Using these tools allows adjustments based on nationality, anthropometric dimensions, and even the sex of workers while assessing the risk of musculoskeletal disorders (39). Through biomechanical simulations, it is possible to prevent musculoskeletal disorders and reduce compensation and work absenteeism, thus effectively lowering costs. The disadvantages of these tools include the need for specialized training, licensing costs, and the installation process (40), while most biomechanical tools only analyze static postures (41, 42). Biomechanical tools are based on models that calculate joint loads, whereas ergonomic methods mainly rely on experimental studies (43).

One of the significant differences between ergonomic and biomechanical tools is their ability to assess the risk of injury (39). The methods that are widely used and suitable for the selected activities are considered in this study (19). Previous studies have compared methods and tools based on general characteristics such as correspondence with a valid reference, criteria for posture classification, association with MSDs, inter-observer repeatability, and exposure factors assessed like postures or body regions, force, and movement repetition (4, 6, 44, 45). Additionally, some studies have compared methods and tools based on outcomes and have been limited to specific methods (46, 47). A key question is whether different tools can be used interchangeably. Any measurement tool used must possess properties that accurately and precisely measure the target. It is possible to apply biomechanical tools across different industries. Since ergonomic methods are developed based on empirical studies in specific industries or organizations, their applicability in other industries or organizations has always been a subject of research. If applicable, what results would be obtained? Employing statistical tests and comparing the results of tools with similar applications could be helpful.

2. Objectives

The primary objective of this study was to compare the methods and tools for assessing the risk of musculoskeletal disorders. Consequently, the risk of musculoskeletal disorders for selected tasks was determined using these tools and methods, and the correlation and agreement between the results of different tools and methods used for each activity was calculated.

3. Methods

3.1. Tasks and Context of Study

This analytical and cross-sectional study was conducted in 2023 within a specific sector of the SAIPA Automobile Part Manufacturing Factory in Iran. Our survey indicated that 72% of workers in this sector reported discomfort in at least one body area, according to the Cornell Musculoskeletal Discomfort Questionnaires. Consequently, all activities in this sector were assessed using various tools and methods. Each worker's activity cycle was meticulously observed and recorded through filming, with dangerous tasks and postures being identified. After casting, parts were transferred to this sector for grinding and cleaning. The activities performed included lifting, grinding, pushing, and lowering. Lifting involved handling parts weighing 36, 7.9, and 3.4 kg at three different workstations. A total of six tasks from six workstations were examined, with each part typically lifted by one worker. The 3.4 kg pieces were moved in pairs, while other pieces were moved individually on the conveyor roller. The pieces were then pushed to the next station, where grinding operations took place, followed by the worker lowering the pieces (Figure 1).

3.2. Data Collection

Data were collected from six workstations involving 33 workers. Each participant first completed an informed consent form and provided essential information such as height and weight. The next step involved analyzing the participants' movements. Due to industry limitations, only photography was feasible for recording movements. The photos were analyzed using Digitizer software, where necessary angles and distances were estimated. The force involved in the pushing activity was calculated using the Danesh Salar Push&Pull and Lutron FG 5020 Force Gauges. Information regarding the time and frequency of work was gathered from daily statistics. Risk assessments were then conducted based on these data. This study received approval from the Ethics Committee of Hamedan University of Medical Sciences (Iran) and adhered to the protocols of both the company and the Ethics Committee.

3.3. Assessment Tools

This industry prioritized risk assessment for six tasks with the potential for musculoskeletal disorders. For this purpose, fourteen tools were used and compared. Biomechanical assessments utilized recorded field data, segmental angles from motion analysis, and the anthropometric dimensions of subjects. Notably, the HCBCF, MAC, NIOSH, and WISHA methods are not designed to evaluate pushing activities; thus, this activity was assessed using other specified methods and tools. The QEC method was employed separately to calculate and compare both load-carrying and non-load-carrying tasks. Asymmetric tasks were analyzed for critical postures using the RULA and REBA methods. While the QEC, RULA, and REBA methods were primarily developed for posture analysis, they were also applied to assess the increase in applied force and improper posture due to load-carrying activities. The tools used included:

3.3.1. 3D Static Strength Prediction Program

This program predicts compression and shear loads imposed on the L4-L5 and L5-S1 intervertebral discs using subjects’ anthropometric dimensions, joint angles relative to each other, and the load's position relative to the body (31, 48).

3.3.2. JACK SIEMENS

Similar to 3DSSPP, this tool predicts L4-L5 compression and shear loads based on subjects’ anthropometric dimensions, joint angles, and load positions (32, 49).

3.3.3. Hand-Calculation Back Compressive Force Equation

The HCBCF equation estimates L5-S1 compressive loads using five variables: Subjects' height and weight, the weight of the hand load, the distance between the hands and the waist, and the trunk angle in the sagittal plane (34).

3.3.4. Manual Handling Assessment Charts

This tool provides an ultimate score using variables such as load weight/frequency, load distance from the body, load vertical height, rotation and bending, lifting with restricted posture, coupling, surface conditions, environmental factors, distance to move the load, path obstacles, and cooperation between subjects (16).

3.3.5. Snook Tables

These tables are designed separately for lifting, lowering, pushing, pulling, and load-carrying tasks. Based on psychophysical data, they consider factors such as the width of the object, distance of lift, and lifting zone (17). They determine the maximum acceptable load for manual materials handling tasks and provide the maximum acceptable weight and force for analysis and population percentiles.

3.3.6. National Institute for Occupational Safety and Health

This method takes into account several factors to determine the recommended weight limit for lifting (18). These factors include the constant load, horizontal and vertical positions of the hands, vertical displacement of the load, angle of asymmetry, repetition of lifting, and quality of hand-coupling. The load-lifting index (LI) is then calculated based on this recommended weight limit and the actual load weight.

3.3.7. Washington Industrial Safety and Health Act

The WISHA Lifting Calculator is a straightforward method that applies NIOSH multipliers to estimate the LI (19, 20). It considers factors such as the hand position at the start of lifting (both vertical and horizontal), frequency, duration, and body twist. However, this method does not account for the vertical travel distance of the load or the hand-to-load coupling.

3.3.8. Key Indicator Method

The KIM-LHC is designed for lifting, holding, and carrying, whereas the KIM-PP is for pulling and pushing tasks (21). For KIM-LHC, factors such as force, repetition, duration, posture, distance between the load and the body, and working conditions are considered. For KIM-PP, load weight, repetition, pulling/pushing speed, posture, and working conditions are assessed.

3.3.9. Strain Index

The strain index is used to determine the risk of upper limb musculoskeletal disorders (15). It evaluates the risk level of a job by considering the intensity and duration of exertion, efforts per minute, hand/wrist posture, work speed, and duration of the task per day.

3.3.10. Rapid Upper Limb Assessment

This method provides a final score when assessing a task (14). It divides the body into two groups for examination and considers body posture, force, static conditions, and repetition of activity as risk factors. The right and left sides of the body are assessed separately.

3.3.11. Rapid Entire Body Assessment

Developed to assess risks of musculoskeletal disorders across the whole body, REBA takes into account the quality of hand-coupling (13). Like RULA, it examines the right and left sides of the body separately.

3.3.12. Quick Exposure Check

Quick exposure check is a rapid risk assessment method for musculoskeletal disorders (12). It calculates scores for body segments and the whole body using worksheets for the observer and the person being evaluated. This method considers body posture, activity repetition, duration, load weight (if carrying), and psychological factors.

3.3.13. Lifting Fatigue Failure Tool

Lifting fatigue failure tool (LiFFT) estimates fatigue failure by considering factors such as load weight, the maximum horizontal distance from the spine, and the number of repetitions (35).

3.3.14. Survival Chance

This tool, developed using a nonlinear approach, estimates survival probabilities based on load magnitude and the number of cycles (36).

The ergonomic methods reviewed have various tables and final scores for determining the risk level and prioritizing corrective actions. Therefore, in both ergonomic methods and biomechanical tools, the results were classified into three risk levels (low risk, moderate risk, and high risk) to facilitate relevant comparisons (50, 51) (Table 1).

| Tools | Original Number of Action Categories | After Classification | ||

|---|---|---|---|---|

| Low Risk | Moderate Risk | High Risk | ||

| Biomechanical tools | ||||

| Compression | 3 | < 3400 | 3400 - 6400 | > 6400 |

| Shear | 3 | < 500 | 500 - 1000 | > 1000 |

| MAC | 4 | 0 - 4 | 5 - 12 | 13 - 20 |

| SNOOK (%) | - | > 90 | 75 - 90 | < 75 |

| NIOSH | 4 | LI ≤ 1 | 1 < LI ≤ 3 | LI > 3 |

| WISHA | 2 | LI < 1 | 1 ≤ LI < 1.5 | LI ≥ 1.5 |

| KIM | 4 | < 10 | 10 - 50 | ≥ 50 |

| Strain index | 4 | SI < 3 | 3 ≤ SI < 7 | SI ≥ 7 |

| RULA | 4 | 1 - 2 | 3 - 6 | ≥ 7 |

| REBA | 5 | 1 | 2 - 7 | 8 - 15 |

| QEC (%) | 4 | < 40 | ≥ 40 - < 70 | ≥ 70 |

| LiFFT (%) | 3 | < 25 | 25 - 50 | ≥ 50 |

| Survival chance (%) | - | > 75 | 50 -75 | ≤ 50 |

3.4. Risk Assessment Calculation and Statistical Analysis

Tasks were assessed using both biomechanical tools and ergonomic methods to determine the risk of musculoskeletal disorders. Statistical analyses were performed using SPSS version 26. Given the qualitative tool measurement scale used in this study, Kendall’s Tau-b correlation coefficient was utilized to assess tool validity, and the kappa coefficient was applied to evaluate tool reliability (52). Kendall’s Tau-b correlation coefficient measures the degree of correlation between the risk levels obtained from one tool and those obtained from another, determining whether one tool could replace another. The kappa coefficient assesses whether both tools consistently report a worker at risk levels 1, 2, or 3. Additionally, the mean and standard deviation of the data were calculated.

4. Results

Data were collected from six workstations. Among the biomechanical tools, the lowering activity (task 6) was identified as the most hazardous, where the maximum compression load was exerted on the L4-L5 disc. The JACK tool predicted the highest compression load on the L4-L5 disc. The lowest disc force was observed in task 2 (grinding activity). The 3DSSPP and HCBCF tools did not classify any activities as high-risk, while JACK indicated L4-L5 shear force in 18.2% of subjects and L4-L5 compression force in 45.5% of subjects as being in the high-risk zone. In the pushing task, average compression and shear loads were predicted to be in the low-risk zone (Table 2 and Figure 2).

| Tasks and Load Weight a | Mean and Standard Deviation of Participants | Tools | Inter-vertebral Disc Force (N) | ||||

|---|---|---|---|---|---|---|---|

| Height (cm) | Weight (kg) | ||||||

| L4-L5 | L5-S1 | ||||||

| Compression | Shear | Compression | Shear | ||||

| Task 1 (6.8 kg) (n = 6) | 175 ± 5 | 75 ± 13 | 3DSSPP | 2988 ± 402 | 433 ± 67 | 3214 ± 438 | 428 ± 63 |

| JACK | 3047 ± 411 | 900 ± 115 | - | - | |||

| HCBCF | - | - | 3300 ± 460 | - | |||

| Task 2 (3.4 kg) (n = 6) | 175 ± 7 | 79 ± 14 | 3DSSPP | 999 ± 111 | 170 ± 22 | 1089 ± 124 | 272 ± 36 |

| JACK | 1135 ± 152 | 239 ± 31 | - | - | |||

| HCBCF | - | - | 938 ± 106 | - | |||

| Task 3 (7.9 kg) (n = 6) | 171 ± 5 | 72 ± 11 | 3DSSPP | 2946 ± 338 | 420 ± 58 | 3202 ± 377 | 422 ± 55 |

| JACK | 3003 ± 349 | 886 ± 99 | - | - | |||

| HCBCF | - | - | 3374 ± 377 | - | |||

| Task 4 (36 kg) (n = 6) | 178 ± 3 | 81 ± 10 | 3DSSPP | 4459 ± 176 | 788 ± 53 | 4923 ± 205 | 744 ± 49 |

| JACK | 6107 ± 294 | 1683 ± 85 | - | - | |||

| HCBCF | - | - | 5922 ± 320 | - | |||

| Task 5 (35 kg) (n = 3) | 177 ± 6 | 80 ± 2 | 3DSSPP | 2543 ± 90 | 5 ± 5 | 2574 ± 94 | 79 ± 7 |

| JACK | 2955 ± 105 | 289 ± 20 | - | - | |||

| HCBCF | - | - | - | - | |||

| Task 6 (36 kg) (n = 6) | 175 ± 2 | 78 ± 5 | 3DSSPP | 5599 ± 191 | 732 ± 28 | 6047 ± 212 | 727 ± 27 |

| JACK | 6753 ± 227 | 1808 ± 57 | - | - | |||

| HCBCF | - | - | 5786 ± 236 | - | |||

a 1, 3, and 4: Lifting; 2: Grinding; 5: Pushing; and 6: Lowering activities; n, number of participants evaluated.

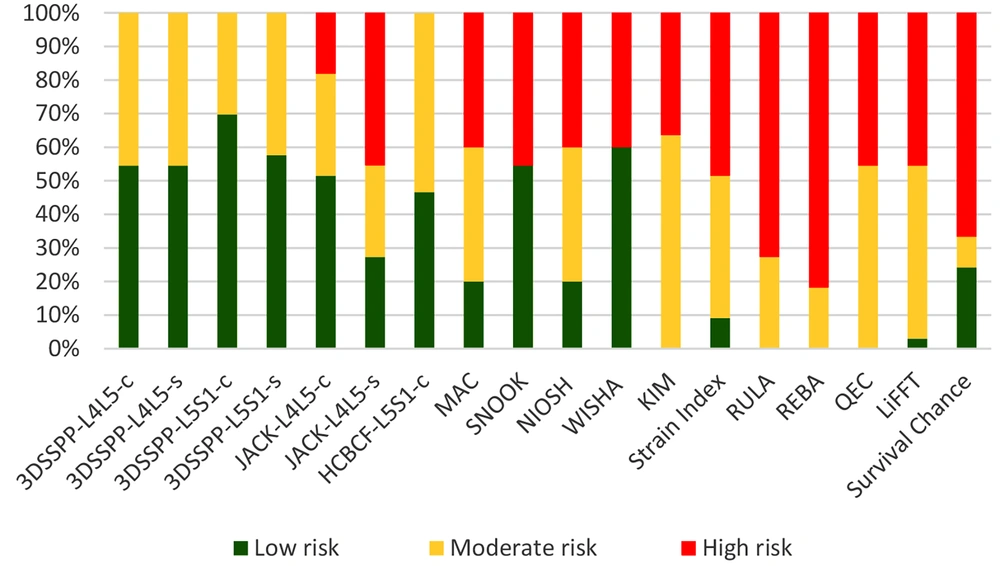

Both lifting (task 4) and lowering (task 6) tasks were identified as high-risk by all methods (Table 3). The MAC and NIOSH methods categorized 20% of tasks as low-risk, 40% as moderate-risk, and 40% as high-risk. Snook’s tables indicated that 54.5% of the tasks were low-risk and 45.5% were high-risk. The WISHA method identified 60% of tasks as low-risk and 40% as high-risk, KIM categorized 63.6% as moderate-risk and 36.4% as high-risk, the strain index (SI) found 9.1% of tasks as low-risk, 42.4% as moderate-risk, and 48.5% as high-risk, RULA identified 27.3% as moderate-risk and 72.7% as high-risk, REBA indicated 18.2% as moderate-risk and 81.8% as high-risk, and QEC identified 54.5% as moderate-risk and 45.5% as high-risk (Figure 2).

| Tools | Task 1 | Task 2 | Task 3 | Task 4 | Task 5 | Task 6 |

|---|---|---|---|---|---|---|

| MAC | 12 ± 0 | 2.17 ± 0.4 | 12 ± 0 | 17.8 ± 0.4 | - | 19 ± 0 |

| SNOOK (%) | 90 ± 0 | 90 ± 0 | 90 ± 0 | 10 ± 0 | 42 ± 2 | 10 ± 0 |

| NIOSH | 1.63 ± 0.01 | 0.44 ± 0.01 | 2.68 ± 0.02 | 6.79 ± 0.12 | - | 7.3 ± 0.27 |

| WISHA | 0.65 ± 0 | 0.42 ± 0 | 0.76 ± 0 | 2.4 ± 0 | - | 3.46 ± 0 |

| KIM | 48 ± 0 | 19 ± 2.4 | 48 ± 0 | 72 ± 0 | 36 ± 0 | 96 ± 0 |

| Strain index | 3.5 ± 0.77 | 3.6 ± 0.75 | 7.7 ± 1.99 | 11.0 ± 2.28 | 1.8 ± 0.64 | 14.5 ± 2.44 |

| RULA | 7 ± 0 | 6 ± 0 | 7 ± 0 | 7 ± 0 | 5 ± 0 | 7 ± 0 |

| REBA | 10 ± 0 | 5 ± 0 | 9 ± 0 | 11 ± 0 | 10 ± 0 | 11 ± 0 |

| QEC (%) | 68.3 ± 1 | 59.7 ± 3 | 68.9 ± 0.9 | 80.6 ± 0.8 | 73.3 ± 2.3 | 82.5 ± 1.6 |

a 1, 3, and 4: Lifting; 2: Grinding; 5: Pushing; and 6: Lowering activities.

b Values are expressed as mean ± SD.

The LiFFT tool classified 3% of tasks as low-risk, 51.5% as moderate-risk, and 45.5% as high-risk, while the survival chance tool classified 24.2% of tasks as low-risk, 9.1% as moderate-risk, and 66.7% as high-risk (Table 4 and Figure 2).

| Tools | Task 1 | Task 2 | Task 3 | Task 4 | Task 5 | Task 6 |

|---|---|---|---|---|---|---|

| LiFFT | ||||||

| Damage | 0.0051 ± 0.00 | 0.0019 ± 0.00 | 0.0063 ± 0.00 | 1.07 ± 0.35 | 0.03 ± 0.01 | 1.44 ± 0.25 |

| Probability of high-risk job | 35.0 ± 0.5 | 25.6 ± 0.5 | 37.1 ± 0.6 | 84.8 ± 1.8 | 56.4 ± 3.2 | 86.7 ± 0.8 |

| Survival chance | 35.5 ± 17 | 92.8 ± 2 | 37.6 ± 15 | -25.5 ± 10 | 70.4 ± 2 | -97.8 ± 13 |

a 1, 3, and 4: Lifting; 2: Grinding; 5: Pushing; and 6: Lowering activities.

b Values are expressed as mean ± SD.

Results showed that, with the exception of the correlation coefficient between QEC and RULA, other correlation coefficients between different tools were statistically significant. According to Table 5, results from the Kendall-Tau-B correlation coefficient indicated that 3DSSPP had a very high correlation (91.3%) with JACK in estimating the L4-L5 compression force. Additionally, 3DSSPP had a very high correlation (87.7%) with JACK in estimating the L4-L5 disc shear force. There was a perfect correlation (1.0) between 3DSSPP and HCBCF in estimating the compression force of the L5-S1 disc. Among the ergonomic tools for MMH, there were very high correlations between the tools. A perfect correlation was observed between the MAC/NIOSH, SNOOK/WISHA, and WISHA/KIM methods. In body posture assessment methods, the highest correlation was between RULA/REBA (77.0%), and the lowest was between RULA/QEC (14.9%) (Table 6).

| Cohen’s Kappa Value | Interpretation of Cohen’s Kappa Value |

|---|---|

| 0 ≥ | No agreement |

| 0.10 - 0.20 | Slight agreement |

| 0.21 - 0.40 | Fair agreement |

| 0.41 - 0.60 | Moderate agreement |

| 0.61 - 0.80 | Substantial agreement |

| 0.81 - 0.99 | Near-perfect agreement |

| 1 | Perfect agreement |

| Paired Methods | Kendall’s Tau-b Correlation Value | P-Value | Kappa | P-Value |

|---|---|---|---|---|

| 3DSSPP.L4L5.C/ JACK.L4L5.C | 91.3 | < 0.001 a | 68.6 | < 0.001 |

| 3DSSPP.L4L5.S/ JACK.L4L5.S | 87.7 | < 0.001 a | 00.0 | 1.00 |

| 3DSSPP.L5S1.C/ HCBCF.L5S1.C | 1.00 | < 0.001 a | 1.00 | < 0.001 |

| MAC/SNOOK | 86.6 | < 0.001 a | 44.4 | < 0.001 |

| MAC /NIOSH | 1.00 | < 0.001 a | 1.00 | < 0.001 |

| MAC/WISHA | 86.6 | < 0.001 a | 44.4 | < 0.001 |

| MAC/KIM | 86.6 | < 0.001 a | 66.7 | < 0.001 |

| SNOOK/NIOSH | 86.6 | < 0.001 a | 44.4 | < 0.001 |

| SNOOK/WISHA | 1.00 | < 0.001 a | 1.00 | < 0.001 |

| SNOOK/KIM | 82.8 | < 0.001 a | 23.8 | < 0.001 |

| NIOSH/WISHA | 86.6 | < 0.001 a | 44.4 | < 0.001 |

| NIOSH/KIM | 86.6 | < 0.001 a | 66.7 | < 0.001 |

| WISHA/KIM | 1.0 | < 0.001 a | 28.6 | < 0.001 |

| Strain index/RULA | 64.5 | < 0.001 a | 37.3 | 0.007 |

| Strain index/REBA | 34.6 | 0.012 b | 36.6 | 0.003 |

| Strain index/QEC | 39.2 | 0.035 b | 61.3 | < 0.001 |

| RULA/REBA | 77.0 | 0.001 c | 74.4 | < 0.001 |

| RULA/QEC | 14.9 | 0.380 | 12.7 | 0.392 |

| REBA/QEC | 43.0 | 0.003 c | 31.3 | 0.013 |

| MAC/LiFFT | 88.0 | < 0.001 a | 72.5 | < 0.001 |

| SNOOK/LiFFT | 97.0 | < 0.001 a | 33.7 | < 0.001 |

| NIOSH/LiFFT | 88.0 | < 0.001 a | 72.5 | < 0.001 |

| WISHA/LiFFT | 96.3 | < 0.001 a | 30.9 | < 0.001 |

| KIM/LiFFT | 80.3 | < 0.001 a | 76.1 | < 0.001 |

| Strain index/LiFFT | 39.3 | 0.028 b | 56.6 | < 0.001 |

| RULA/LiFFT | 19.3 | 0.274 | 8.3 | 0.563 |

| REBA/LiFFT | 47.3 | 0.003 c | 26.3 | 0.033 |

| QEC/LiFFT | 97.0 | < 0.001 a | 94.1 | < 0.001 |

| MAC/survival chance | 72.2 | < 0.001 a | 47.9 | < 0.001 |

| SNOOK/survival chance | 31.0 | 0.041 | 24.0 | 0.035 |

| NIOSH/survival chance | 72.2 | < 0.001 a | 47.9 | < 0.001 |

| WISHA/survival chance | 47.6 | < 0.001 a | 31.8 | 0.010 |

| KIM/survival chance | 50.4 | < 0.001 a | 26.7 | 0.005 |

| Strain index/survival chance | 52.0 | < 0.001 a | 13.6 | 0.236 |

| RULA/survival chance | 86.6 | < 0.001 a | 48.8 | < 0.001 |

| REBA/survival chance | 77.2 | 0.001 c | 21.9 | 0.061 |

| QEC/survival chance | 31.0 | 0.041 | 6.3 | 0.550 |

a P-value < 0.001.

b P-value < 0.05.

c P-value < 0.01.

Statistically, all correlation coefficients, except for the one between RULA and LiFFT, showed significant relationships. Results from the Kendall-Tau-B correlation coefficient demonstrated that LiFFT had the highest correlation with MMH methods. It had the lowest correlation with the KIM method (80.3%) and the highest correlation with SNOOK's method (97.0%). Lifting fatigue failure tool also showed a very high correlation (97.0%) with the QEC method but a low correlation with other body posture assessment methods. The survival chance tool displayed the lowest correlation with Snook's method (31.0%) and the highest correlation with NIOSH and MAC methods (72.2%). Moreover, this tool showed the highest correlation with the RULA method (86.6%) and the lowest with the QEC method (31.0%) (Table 6).

5. Discussion

This study was conducted to compare risk assessment tools and methods for identifying tasks with the risk of musculoskeletal disorders in a sector of the SAIPA automobile part manufacturing factory.

5.1. Biomechanical Tools

JACK and 3DSSPP estimated that lowering activities exert greater forces on the intervertebral disc, whereas HCBCF did not show a difference between the lowering and lifting tasks (task 4). Furthermore, 3DSSPP and HCBCF assessed the lowering task (task 6) as moderate risk. This may be attributed to the lower sensitivity of these models to asymmetrical activities. Rajaee et al. (48) have recommended that 3DSSPP and HCBCF be used only for symmetric activities. The workers' anthropometric characteristics significantly influenced the disc forces during lifting tasks (tasks 1 and 3). Variations in anthropometric characteristics might explain why, despite the heavier load of task 3 compared to task 1, the force applied to the disc was less in task 3. The grinding activity (task 2) was identified as a low-risk activity. In this task, the force applied to the disc was small compared to other tasks due to the lower load weight, smaller trunk angle, and shorter distance between the hand load and L4-L5 and L5-S1 discs.

Only JACK identified high risk in some tasks (Figure 2). In a comparison between JACK and CATIA, Polášek et al. noted that the Lift-Lower values in JACK were higher, with a difference of about 13% between the two tools. This discrepancy may result from the more precise settings of inputs in JACK. Another notable difference is in the settings of body part angles, which influence the compressive forces (40). While JACK could accurately analyze the body, manually entering the angles directly into the model proved challenging (53). 3D static strength prediction program and JACK were highly correlated in estimating compressive and shear forces (91.3% and 87.7%, respectively); however, they only showed excellent agreement for the estimated compressive force (68.6%). Additionally, 3DSSPP and HCBCF demonstrated a high correlation and perfect agreement, suggesting that they could be used interchangeably.

5.2. Ergonomic Methods

The load-carrying methods demonstrated a good positive correlation with each other, indicating that an increase in the scores of one method was associated with increases in the scores of the others. The lowest value of the kappa statistic between SNOOK and KIM was 23.8%. There was perfect agreement and correlation between MAC and NIOSH as well as between SNOOK and WISHA. Abedini et al. also noted in their review that MAC and NIOSH are interchangeable (54). National Institute for Occupational Safety and Health and WISHA showed a 44.4% agreement. In Asadi et al.'s study, the kappa value was 0.29% (55). This latter study did not explain the motion analysis method used, which could differ from the one used in the current study.

Rapid upper limb assessment, REBA, and QEC identified none of the tasks as low risk (Figure 2). Rapid upper limb assessment and REBA methods had a 77% correlation and a 74% agreement. These findings align with those of Chiasson et al., who reported an 82% agreement (46). There was no significant relationship between RULA and QEC methods, with a 43% correlation and a 31% agreement between REBA and QEC. In the study by Chiasson et al., these agreements were 45% and 46%, respectively (46). This could be attributed to the fact that in the QEC method, the questionnaire was completed by the worker, potentially introducing bias. In the study by Unver et al., the score of RULA was higher than that of QEC (56). Kee expressed that the risk levels assessed by RULA were more significantly associated with musculoskeletal disorders (57). Joshi and Deshpande hypothesized that REBA is more suitable for assessing loads of 5 to 10 kg, while RULA is better suited for loads greater than 10 kg; additionally, it was noted that there were postures where the assessment results were not sensitive and the assessment scores did not change (58). The strain index had the highest correlation with RULA (64.5%), while it had the lowest correlation with the REBA method (34.6%). This discrepancy can be partly explained by the fact that both the strain index and the RULA method were developed for assessing upper limbs. Garg et al. noted that the strain index was appropriate for estimating the risk of musculoskeletal disorders of the hands but stated that when exposure increased, a higher risk was not observed (59). Body assessment methods revealed that the grinding task (task 2) posed a moderate risk due to the neck deviation from its neutral posture.

5.3. LiFFT and Survival Chance Tools

Lifting fatigue failure tool demonstrated a good correlation with manual materials handling methods but a lower correlation with body posture assessment methods. It required three variables as inputs, which are also crucial in MMH methods. The high correlation between LiFFT and the QEC methods could be due to the lower accuracy of the QEC method. Survival chance indicated that 66% of workers had no chance of survival, showing a good correlation with the RULA, REBA, NIOSH, and MAC methods. Survival chance reported a low risk for the grinding activity because it focuses on loads on the lumbar disc and does not account for the force applied to the cervical disc. Therefore, this tool is not deemed suitable for assessing this activity. Survival chance calculates the force applied to the disc using biomechanical tools. Thus, it showed a moderate risk for this activity, considering the daily frequency of pushing activity. The results of assessing this tool for activities 1 and 3 (lifting) could be explained by considering the anthropometric differences among subjects.

The ergonomic methods used in this study feature specific and varied tables and final scores for determining risk levels. Consequently, to compare these tools, the raw scores were qualitatively categorized. Although the raw scores of the tools and methods were not identical, they were placed in the same qualitative category (Table 3 and Figure 2). In ergonomic risk assessment, it is crucial to account for static activities, transportation, movements of heavy objects, environmental conditions, and inappropriate body postures (60). Takala et al. (6) and Chiasson et al. (46) noted the difficulty in determining the best method for estimating the risk of musculoskeletal disorders. However, in industries with multiple risk factors, it is essential to select a method that addresses all these risks. Choosing the appropriate method and tool requires knowledge and awareness of their limitations and advantages, which could lead to more accurate musculoskeletal risk assessments (Table 7).

| Tools | Limitations | Advantages |

|---|---|---|

| 3DSSPP | Need skills: Should be used for symmetrical activity | Considering anthropometric dimensions and sex; using different databases; simulation of activities |

| JACK | Requires great skills | Considering anthropometric dimensions and sex; using different databases; simulated activities, and greater accuracy are needed. |

| HCBCF | Should be used for symmetrical activity; not suitable for push/pull tasks | A simplistic quantitative method |

| MAC | Not suitable for push/pull tasks | A checklist for a quick initial assessment; considering environmental factors; assessment of individual and team carrying and lifting; including key elements of NIOSH |

| SNOOK | Designed according to psychophysical criteria | Can be evaluated for push/pull tasks |

| NIOSH | Neglecting worker characteristics, environmental conditions, and different populations and ethnicities. Seems to be conservative, and the basis of its design is 75% of the population of female workers. Its asymmetry coefficient needs to be re-examined. Not suitable for push/pull tasks | Requiring little training time. Its criteria are based on biomechanics, physiology, and psychology. Consider the type of task. |

| WISHA | It only aims to check the weight of the load. Not suitable for push/pull tasks | A checklist for quick initial assessment |

| KIM | It is not suitable for team load assessment | Ability to assess push/pull tasks; ability to assess lifting, holding, carrying, and manual functions; its criteria are based on biomechanics, physiology, and psychology. |

| Strain index | Accurate scoring of force is difficult in complex tasks. | Places greater emphasis on force. Correlation of SI score and carpal tunnel syndrome |

| RULA | If there are different postures, the assessor must decide which one should be checked or whether all the postures should be checked separately. Pays attention to the upper part of the body. If a frequent posture is slightly inappropriate, a low score may be calculated. | A quick assessment of tasks; having a good relationship with musculoskeletal disorders, and assessing the upper body posture |

| REBA | If there are different postures, the assessor must decide which one should be examined or whether all the postures should be checked separately. | Quick assessment of tasks; examining static and dynamic tasks; compared to RULA, examining coupling in the handling of loads |

| QEC | Since workers' comments must be recorded, the results may be biased. It provides little guidance on factors that need intervention. | With a quick review, it provides an initial list of factors to start the intervention. Requiring little training time. Considering workers' opinions. Assessment of static and dynamic activity |

| LiFFT | Injury estimation only in the waist; ignoring age, sex, and anthropometry | Ease of use; prediction of cumulative injury and risk of injury in single-task and multi-task activities; possibility of predicting the effect of the intervention; considering the weight of the load, frequency, and distance of the load from the body |

| Survival chance | It is established based on in vitro data: A multiplicative exponential equation. | Considering the magnitude and frequency of the load |

5.4. Limitations of the Study

This study faced several limitations. The primary limitation was the motion capture system used to obtain the relative joint angles (30, 61). Due to restrictions in the industry, only photography was feasible. Additionally, the sample size was relatively small for performing the risk assessments comprehensively. It is recommended that future studies involve larger sample sizes. Data were collected from six workstations involving 33 workers, but including a wider variety of tasks and postures could potentially enhance our findings and conclusions.

5.5. Conclusions

When recruiting workers, it is crucial to pay greater attention to physical and anthropometric characteristics. Suitable anthropometric characteristics can somewhat reduce the compressive and shear loads on the intervertebral discs. We utilized fourteen different methods and tools, each with specific applications, yet none were comprehensive enough to assess the complex activities typically found in industry. Consequently, these activities require the use of appropriate tools and methods. Since biomechanical tools provide quantitative results and ergonomic methods yield more qualitative data, the purpose of the evaluation will dictate the choice between biomechanical tools and ergonomic methods.

Biomechanical tools offer detailed reports to assessors. Besides estimating compressive and shear forces on different limbs, JACK also provides fatigue and ergonomic analyses similar to those of NIOSH, RULA, or the energy expended by a simulated human model. These features are less prevalent in 3DSSPP. Ease of use and accuracy are vital factors in selecting biomechanical risk assessment tools, and experienced assessors can effectively utilize JACK, 3DSSPP, and HCBCF.

Identifying work environment risk factors and selecting the primary risk are crucial steps in choosing ergonomic methods. For assessing MMH activities, a combination of biomechanical tools and ergonomic methods is more suitable. For rapid assessments, ergonomic methods are beneficial. KIM-PP is preferred for pushing tasks. Depending on the task and environmental conditions, NIOSH is suitable for lifting loads, but MAC should be used in unsuitable conditions. According to injury risk results, KIM is more conservative and suitable for workplaces involving vulnerable individuals.

Studies on body posture assessments indicate that the relationship between RULA and musculoskeletal disorders is more significant, whereas REBA is used in situations involving gripping and dynamic activities. The strain index is appropriate for tasks involving repetitive hand activities. Quick exposure check is an effective starting point for interventions as it provides an initial risk list. It is important to clarify the concepts in the questions and supervise workers before they complete the form. Lifting fatigue failure tool showed good agreement with load-carrying methods, making it useful in assessing load-carrying, especially for multi-tasking and repetitive tasks. Survival chance had moderate agreement with NIOSH, RULA, and MAC, making it suitable for tasks assessed with these methods. Incorporating new technologies and refining the mentioned methods to include factors like sex, environmental conditions, and other relevant factors can enhance musculoskeletal disorder risk assessments. Despite the development of various methods, there is still a need for a novel method tailored to specific jobs, taking into account the corresponding risk factors.