1. Background

Metalworking fluids are a complex mixture of chemicals that were used for lubricating, cleaning, cooling, corroding and rusting inhibitors, and removing chips in a wide range of processes, such as machining, grinding, metal processing, cutting and shaping metal (1-5). Mist mineral oils are generated in industrial processes through aeration, contact with fast-moving surfaces and high temperature (6). This phenomenon could lead to occupational oil mist exposure with subsequent respiratory and skin problems in exposed individuals (7-10).

NIOSH estimates that 1.2 million people in the United States are exposed to mineral oils (11). Mineral oils with diverse chemical compositions are used in industrial processes. Mineral oils lose their original chemical and physical properties and are generally refined and recycled (12). Depending on the quality of refining processes, recycled mineral oils contain toxic chemicals such as N-Nitroso compounds, triethanolamine, diethanolamine, formaldehyde, polyaromatic hydrocarbons, and alkanolamines derivatives, which could be detrimental to the health of exposed personnel (13, 14).

The IARC classifies mists of poorly refined mineral oils as carcinogen group one (15). Different studies also identify exposure to the mists of poorly refined mineral oils as causing cancers of the larynx, sinuses, pancreas, testicles, bladder, rectum, colon, and skin (16-20). According to evidence pertaining to the carcinogenicity of poorly refined mineral oil, ACGIH has recommended separate threshold limit values for pure and highly refined oil at 5 mg/m3. However, a numerical threshold value was not considered for poorly and mildly refined oil. Instead, the icon “L” was introduced to signify the lowest possible level (21).

International organizations (22-24) and researchers (11, 13, 25) have offered various analytic methods for measuring occupational exposure to mists of mineral oils. A common feature of the analytical methods, presented by NIOSH No.5026 (23) and NIOSH No.5524 (24), is the lack of specificity for analysis of toxic ingredients found in mineral oils. These methods do not recognize carcinogenic ingredients of mineral oils that would allow for a precise evaluation of occupational exposure. This may be done for poorly and mildly refined oil using recent TLV introduced by the ACGIH (26). Generally, complementary methods were used for toxic ingredients in mineral oils, such as formaldehyde (27) and N-Nitroso compound (28). Meanwhile, some authors have proposed the separate use of FT-IR and IR spectroscopy for the analysis of formaldehyde and N-Nitroso compounds, respectively (29-31). The FT-IR spectroscopy was credited for higher speed, sensitivity, accuracy, resolution, reliability, and signal-to-noise ratio, compared to the IR method (32-36).

2. Objectives

The objective of this study was to develop a more sensitive method using FT-IR spectroscopy for the analysis of mineral oil and its toxic ingredients.

3. Methods

Highly and poorly refined mineral oil samples with prior chemical analysis were obtained from a manufacturing automobile engine plant. To clarify particulate matter, highly and poorly refined mineral oil samples were centrifuged twice at 6000 RPM, for 10 minutes each time. Using the Sartarius analytical balance with 0.01 mg resolution Model No. TE1245, 1 mL of either mineral oil was subsequently weighed and its density was determined. Highly and poorly refined mineral oil samples were diluted in carbon tetrachloride (grade 99.98%), purchased from Merck Co.

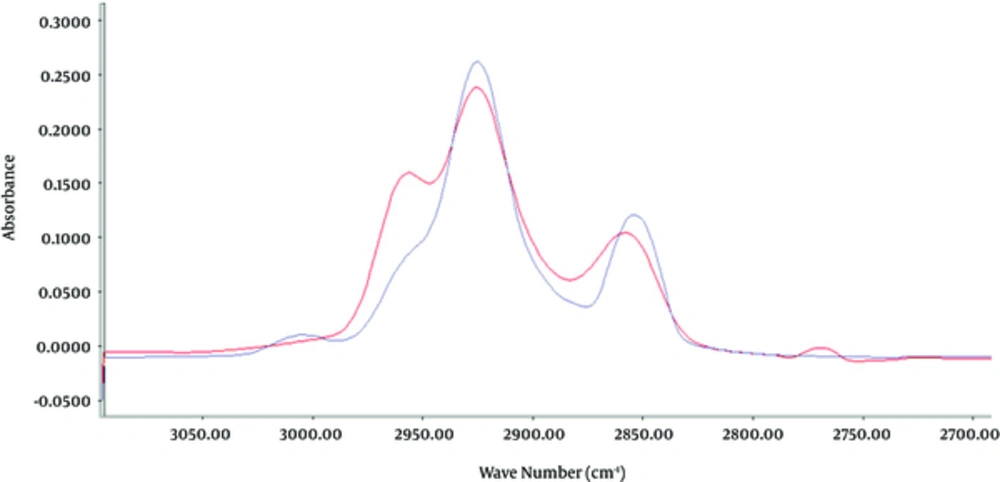

Mixed cellulose filters purchased from SKC Co. were used in the preparation of spiked samples for highly and poorly refined mineral oil samples in the range of 10 to 2,250 µg/sample. Spiked samples were placed in 15 mL Falcon tubes and extracted with 10 mL of carbon tetrachloride. Blank samples were also prepared from carbon tetrachloride and blank mixed cellulose filter. Samples were scanned by FT-IR (WQF 510A model) in the region of 2796 - 3031 cm-1.

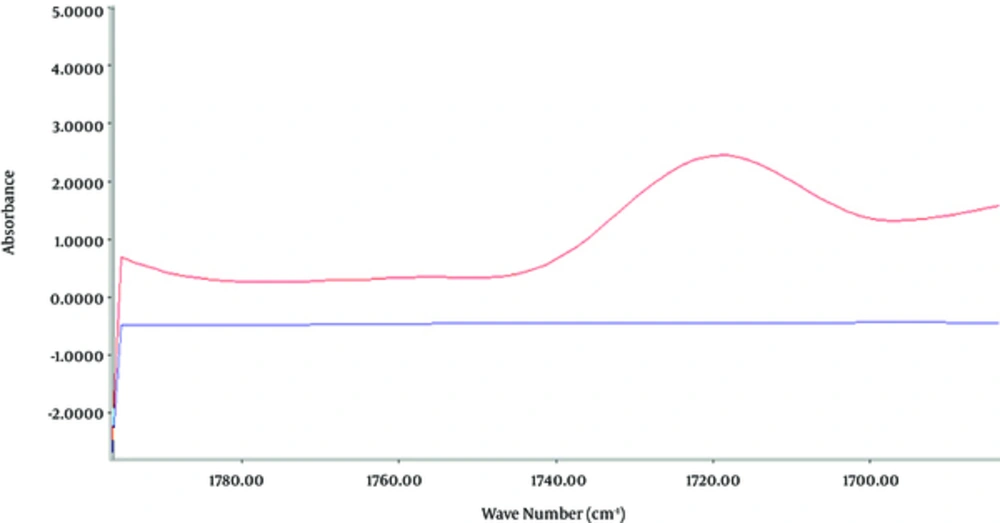

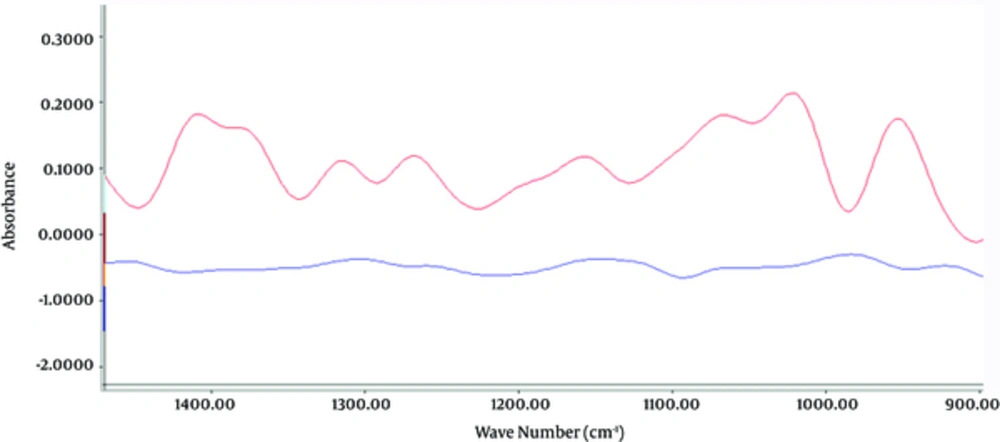

To determine the toxic ingredient of poorly refined mineral oil samples, the presence of formaldehyde and N-Nitroso compounds were detected by the functional groups C = O and C - H at 1720- 2815 cm-1 (34, 36) and of N-N and N = O at 925 - 1500 cm-1 (31, 37), respectively.

The validity of the FT-IR spectroscopy method for analysis of highly and poorly refined mineral oil was examined according to the procedure given by Chan (2008) (38). Spiked and control filters in the range of 10 to 2250 µg/sample were prepared for calculation of linear range concentration. Also, the LOD, LOQ, inter-day and intra-day accuracy and precision (coefficient of variations; inter and intra-day), of highly and poorly refined mineral oil were analyzed separately.

The same set of spiked and control filters with mineral oil was also prepared for analysis by the NIOSH method No. 5524 (24) by adding various amounts of highly pure mineral oil to PTFE membrane filters in the range of 10 to 2250 µg/sample. Spiked and control filters were dried in a desiccator for twenty four hours and weighed by analytical balance. All spiked and control filters were kept in the refrigerator for the next step of analysis.

Filters were equilibrated for 2 hours in a desiccator filled with calcium sulfate, weighed with analytical balance. Each spiked and control filter was placed side up in the filtration funnel and connected to the vacuum suction. A total of 10 mL of ternary solvent consisting of dichloromethane: methanol: toluene (1:1:1) was poured over the filter. Subsequently, binary solvent consisting of methanol: water (1:1) was poured twice over the filter and the solvents were removed within 5 minutes. Filters were removed from the filter funnel and placed over a metal screen under the fume hood and dried for 2 hours. Each spiked and control filter was weighed with analytical balance. Weight of mineral oil of each filter was calculated with regards to pre and post weight by the spiked PTFE and weight of control filters.

For the final phase of validation of this study, data from 2 sets of identical spiked filters (four sets of 10, 25, 50, 80, 125, 300, 500, 1,000, 1,500, and 2,250 as µg/sample) were analyzed according to NIOSH No. 5524 and FT-IR, simultaneously. The absolute differences between the original spiked samples and corresponding data obtained from the NIOSH method No.5524 and FT-IR methods were then compared statistically using one sample t test. The Mann-Whitney test was also used to compare the difference between accuracies and precisions, obtained for the highly and poorly refined oil analyzed using the FT-IR method.

4. Results

Standards of either highly and poorly refined mineral oil samples in the range of 10 to 2,250 µg/sample were prepared and analyzed by FT-IR spectroscopy in the region of 3031 - 2796 cm-1 (Figure 1).

Representative quantitative linear range concentration of standards (10 - 2250 µg/sample) was determined for highly and poorly refined oil by Y = 0.377X + 0.112, r2 = 0.9984 (P < 0.001), and Y = 0.51X + 0.609, r2 = 0.9973 (P < 0.001) formula, respectively. Intra-day and inter-day variation of highly and poorly refined mineral oil standards in range of 10 to 2250 µg/sample was also measured (Table 1). Average accuracies of highly and poorly refined oil standards were 1.4 and 0.54, respectively (Table 2).

| Inter/Intra-Day Variation Highly/Poorly Refined Mineral Oil | Range of Mineral Oil Standards as µg/Sample | Over All CV% | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 10 | 25 | 75 | 100 | 250 | 750 | 1500 | 2250 | ||

| Intra-Day CV% Highly Refined Oil | 7.25 | 6.00 | 3.59 | 4.15 | 8.38 | 3.78 | 0.42 | 0.32 | 5.08 |

| Intra-Day CV% Poorly Refined Oil | 5.35 | 6.97 | 5.08 | 5.28 | 4.43 | 5.60 | 3.66 | 0.91 | 5.18 |

| Inter-Day CV% Highly Refined Oil | 6.08 | 3.74 | 1.31 | 1.53 | 6.70 | 3.45 | 0.93 | 0.07 | 3.61 |

| Inter-Day CV% Poorly Refined Oil | 6.93 | 6.28 | 4.29 | 3.52 | 7.48 | 5.51 | 4.69 | 1.74 | 5.23 |

Abbreviation: CV, Coefficient of variations.

| Mineral Oil | Weight Range of Standards µg/Sample | Accuracy | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 10 | 25 | 75 | 100 | 250 | 750 | 1500 | 2250 | ||

| Highly refined | 100.95 | 100.62 | 97.96 | 101.05 | 97.86 | 102.48 | 98.39 | 100.39 | 1.4 |

| Poorly refined | 99.8 | 101.22 | 98.83 | 100.55 | 100.71 | 99.8 | 99.89 | 100.04 | 0.54 |

Mann-Whitney test results showed no statistically significant difference between accuracies obtained from highly refined mineral oil compared to poorly refined mineral oil in the linear range concentration (P < 0.05). According to the data, LOD and LOQ measure for the analysis of highly and poorly refined oil, using FT-IR method, were 2.61, 8.61 and 2.22, 7.34 µg/sample, respectively.

Toxic ingredients of poorly refined mineral oil samples were determined according to the FT-IR spectrum for optimal IR absorption at wave lengths of 1,720 to 2,815 cm-1 and 925 to 1,500 cm-1, due to the presence of functional groups C = O and C - H corresponding to formaldehyde (34, 36) and functional groups of N - N and N = O, indicating N-Nitroso compounds, respectively (31, 37) (Figures 2 and 3). Highly refined mineral oil did not produce the same spectrum as poorly refined oil, which was associated with C - H, C = O and N - N, N = O functional groups.

Comparison of the results drawn from sample analyses, according to the NIOSH method No.5524 and FT-IR analytical methods showed that the difference between the spiked samples in the FT-IR method was lower than the data obtained through NIOSH method No.5524. One sample t Test results also showed that the average differences of the above mentioned tests were not statistically significant (P < 0.003) (Table 3).

| Concentration, µg/Sample | FT-IR | FT-IR Mean Absolute Difference | NIOSH-5524 | NIOSH-5524 Mean Absolute Difference |

|---|---|---|---|---|

| 10 | 11.5 (1.3) | 1.5 | 12.5 (1.3) | 2.5 |

| 25 | 27.0 (1.4) | 2.0 | 22.9 (0.6) | 2.2 |

| 50 | 50.8 (2.6) | 2.3 | 51.0 (4.2) | 3.5 |

| 80 | 80.5 (2.6) | 2.0 | 76.8 (2.2) | 3.3 |

| 125 | 124.7 (4.9) | 4.2 | 122.4 (7.4) | 6.8 |

| 300 | 298.4 (3.9) | 3.3 | 295.2 (7.9) | 8.3 |

| 500 | 503.8 (6.1) | 5.8 | 505.3 (9.0) | 9.3 |

| 1000 | 1007.5 (4.9) | 7.5 | 1009.3 (12.6) | 13.8 |

| 1500 | 1507.0 (11.5) | 11 | 1495.5 (24.2) | 20.5 |

| 2250 | 2251.0 (4.5) | 3.5 | 2252.3 (6.3) | 5.8 |

aValues are expressed as mean (± SD).

5. Discussion

Since 2009, there have been 2 TLVs for mineral oils. For highly refined oil, this was done at TLV-TWA = 5 mg/m3 and for poorly refined mineral oil at the lowest possible level (26). However, the existing methods did not distinguish the quality of mineral oils. For this reason, researchers developed methods to determine the toxic ingredients of mineral oils, such as formaldehyde and N-Nitroso compounds by liquid chromatography-mass spectrometry (39) and gas chromatography/mass spectrometry (40), respectively. However, the method developed using FT-IR in this study showed 3 unique qualities in the quantitative and qualitative analyses of highly and poorly refined mineral oils.

Firstly, the proposed method with default sample volume of 1000 liters, as required by the NIOSH method, could offer a linear range concentration of 10 to 2250 µg/m3 for the analysis of mineral oil, irrespective of quality. The linear range analysis of mineral oils in this study was more sensitive than the reported data from the NIOSH method No. 5524 (24).

Secondly, the proposed FT-IR method offers an opportunity for qualitative analysis of poorly refined mineral oil containing formaldehyde and N-Nitroso compounds. Furthermore, in this study, the method used to analyze toxic ingredients contained in mineral oils did not require complex instrumentation as reported earlier (39, 40). Instead, in this study, these compounds were recognized by their strong IR absorption of the aldehyde and N-Nitroso compounds' functional groups, present only in poorly refined mineral oil as an additive or a byproduct of lathe processes (28, 41).

Thirdly, comparisons between the mean absolute difference of duplicate spiked samples analyzed using the FT-IR method and the reference NIOSH method No.5524, showed that the FT-IR method produced comparable and better results. Generally, the presented data in this study, with regards to accuracy, precision, LOD and LOQ, was superior compared to the published validation parameters of the methods presented by NIOSH (24), HSE MDHS NO. 84 (22) ASTM method (25).

Overall, the FT-IR spectroscopy method recommended by the present study offers an alternative method for the analysis of the mists of mineral oil, other than methods offered by scientific organizations such as NIOSH. The developed method of this study was valuable, where the quantitative and qualitative analysis of mineral oils of either poorly or highly refined mineral oil mists was required.