1. Background

The treatment and disposal of sewage sludge are costly procedures and environmentally susceptible as well as unavoidable problems arising from wastewater treatment plants (WWTP). It is also an emergent problem worldwide because sludge production will continue to increase as new wastewater treatment plants are built, and environmental quality standards become stricter. In addition, sewage sludge contains great quantities of organic matter, pathogenic microorganisms and chemical pollutants which if not properly handled and disposed may create considerable health problems (1, 2).

Sludge (Biosolids) is composed mostly of solid materials generated during wastewater treatment processes. Sludge treatment and disposal are probably the most costly operations in waste-water treatment plants. Now, sludge disposal is one of the most significant challenges by all environmentalists and in this regard, new standards have been established by the United States Environmental Protection Agency (USEPA) in 1989. Title 40 CFR Part 503 of USEPA regulations illustrates the matter and determines the definitions, objective and applicability, common necessities, contaminant limits, management practices, operational standards, control of pathogens and vectors, sampling and analysis, frequency of monitoring, recordkeeping, and reporting (2).

In advanced countries, sewage sludge monitoring before its application on land is an ordinary enforced practice, however in Iran, there is no written law concerning sludge, although they are mostly being applied in lands (3). Also, currently, there are no major activities for controlling pollution of waste sludge’s of municipal WWTPs in Iran. Consequently, it is generally raw and untreated (4, 5). Sludge treatment plants usually have a high annual cost and intensively need a professional operatory. Thus, cost-effectiveness and simpler methods for sludge stabilization should be considered (6).

The procedure of sludge stabilization is to break down the organic compounds of the sludge to decrease its mass and to achieve a product that is less odorous as well as safer from a public health point of view. Stabilization of sludge includes the following steps: anaerobic and aerobic digestion, composting, lime stabilization, and heat treatment (4, 7). Lime is considered one of the most universal alteration compounds for stabilization of sewage sludge, as it plays a critical role in decreasing the pathogenic content of sludge, accessibility of heavy metals, and the relevant environmental risks, as well as enhancing its agricultural benefits (8).

This procedure has been suggested for the advanced treatment of sewage sludge in the related EU working document on sludge application (9). Lime addition is normally more gainful and easier than alternative options, and the microbial quality of the resulting sludge is far superior. These plants may be effortlessly added to the processes that have insufficient capacity to meet regulatory necessities (10). In this process, adequate lime is added to raw sludge to increase its pH (11). Lime, added as Ca(OH)2 or CaO, is an inexpensive chemical that is used as a flocculating agent to control odor in wastewater treatment plants.

The lime stabilization process consists of adding a lime slurry to the liquid sludge to achieve a pH higher than 12. The needed lime dose varies with the kind of sludge and also concentration of solids (7). High pH produces an environment that stops or considerably decelerates the reactions of microorganisms that can otherwise lead to production of odor and also attraction of different vectors. Sludge will not decompose, produce odors, or create a health hazard as long as the pH is retained at this level. In addition, the procedure can inactivate viruses, bacteria, and other present microorganisms (12).

Most lime treatment facilities have the flexibility to generate either class A or class B regulations suggested by USEPA (13). To meet Class B criteria, the pH of the sludge must be increased to more than 12 for 2 hours and afterward retained at more than 11.5 for 22 hours. To meet Class A, the Class B raised up pH requirements are combined with higher temperatures (70°C for 30 minutes) (14). On the basis of the classes, the lime-stabilized sludge possibly reused as a cover for solid waste in landfill, marketable manure or soil conditioner (15).

2. Objectives

In this research, the extent of stabilization and potential reuse of waste sludge from Shoosh municipal WWTPs in Tehran city was considered. This plant works on the basis of extended aeration of the activated sludge process. Additionally, this study was carried out to evaluate the microbial quality of waste sludge from Shoosh WWTP and moreover, to upgrade Shoosh WWTP by lime stabilization of waste sludge.

3. Materials and Methods

3.1. Lime Sludge Stabilization Experimental Setup

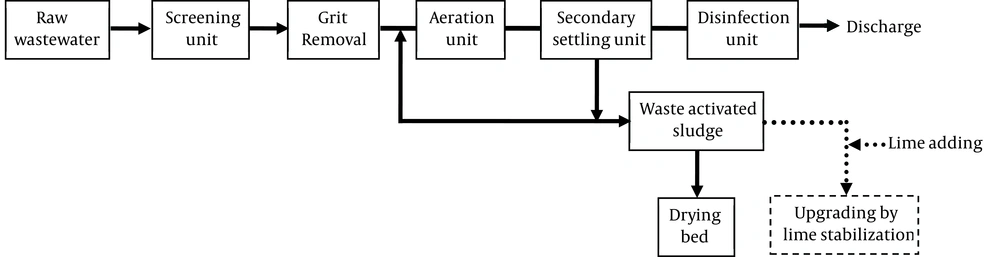

This work was performed on the waste sludge produced from Shoosh WWTP (Figure 1), in 2011. Two separate steps of this work consisted of:

1) Investigation of microbial quality and potential reuse of waste sludge. All samples were taken at the sludge outlet from Shoosh WWTPs and analyzed for fecal coliforms (FC) and density of viable helminthes ova. In addition, the characteristics of waste sludge were compared with the well-stabilized sludge criteria, suggested by USEPA (16).

2) Upgrading the microbial quality of waste sludge from Shoosh WWTPs with lime stabilization.

A glass reactor with 10 L capacity and a blender were employed in this study. First, the reactor was filled by untreated sludge of Shoosh WWTPs and then adequate quantity of hydrated lime was added and mixed. Microbial quality of lime-stabilized sludge was checked for 6 weeks in the reactor. During this stage, pH, FC and density of viable helminthes ova were determined and compared with sludge stabilized criteria suggested by USEPA (16). With the purpose of determining the optimal ratio of slacked lime, this step was repeated 4 times. The optimal ratio was the amount of slacked lime which could elevate the pH of sludge over 12 for 2 hours and retain it above 11 for 4 weeks (15).

3.2. Analytical Methods

Total solids and volatile solids of samples were determined according to the Standard Methods (16, 17). The pH was measured by a pH meter (Metrohm Herisau, Switzerland Ultra Basic, U.S.) in deionized water using 1:2 (w/v) sludge–solution ratio (extraction time 30 minutes). Fecal coliform bacteria were determined on a wet weight basis as pathogen indicators and tested in accordance with the Analytical and Monitoring Methods of Water and Waste-water (15). Fecal coliform was initially identified using lactose peptone broth, and confirmed on EC broth. All analyses were performed according to the standard methods (16, 17).

4. Results

Table 1 presents the characteristics of waste sludge from Shoosh WWTP. The minimum number of FC and density of viable helminthes ova are 6 × 1011 MPN/g of dry solids and 258 ova/4 g of dry solids, respectively. On the basis of the USEPA standards for well-stabilized sludge, maximum quantities of fecal coliform density are 1000 and 2 × 106 MPN/g of dry solids for class A and class B, respectively, and viable helminthes ova density is 1ova/4 g of dry solids for class A (16). There were significant differences between these criteria and characteristics of this sludge (P <0.01). As presented in Table 2, the ratios of added lime (in gram) to dry sludge (in gram) in 4 series of reactor loading were 0.2, 0.25, 0.3, and 0.35, respectively. Table 2 presents the findings of the viable helminthes ova analysis on the treated sludge.

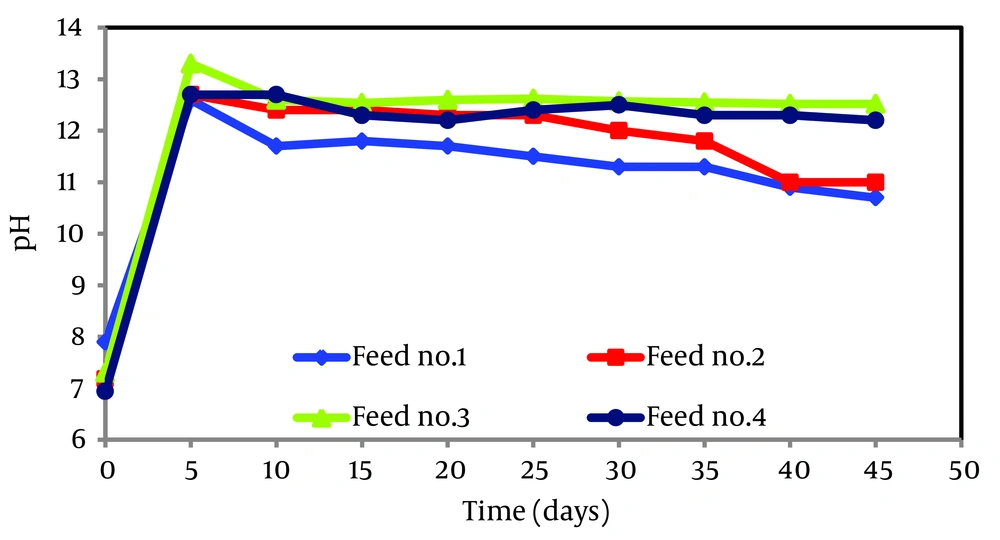

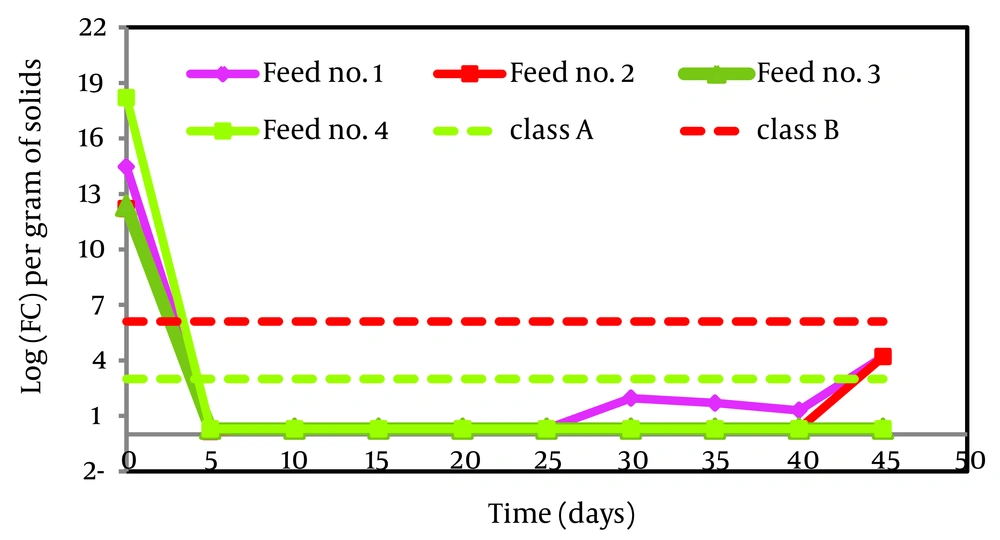

according to these records, there are significant differences (P < 0.01) between these quantities and standard value (1 MPN/4 g dry solids related to class A of USEPA standards) (18). Figure 2 illustrates the pH variations of lime-added sludge with respect to time. This figure showed that except step 1 with 5 days holding pH > 12, the other steps held on pH higher than 12 more than 45 days. Figure 3 illustrates the variation of the fecal coliform density in lime-added sludge in 4 times of reactor loading and the amounts of fecal coliform in classes A and B of USEPA standards. This figure shows that, after the lime was mixed to sludge, fecal coliform was reduced to lower than 1000 MPN/g.DS, and did not increase after 45 days, except for first and second steps.

5. Discussion

At the time of this work, specific standard for reuse and disposal of raw and treated sludge was not published by Iranian Department of Environment (DOE) (6). Consequently, other reliable criteria such as USEPA indices are used (16). Comparison of the microbial quality of waste sludge in Shoosh WWTPs and USEPA criteria revealed that the sludge was not in class A or B conditions. Therefore, it should not be disposed to the environment or reused for any purpose (19). This finding was in consistent with the previous study of Farzadkia on some wastewater treatment plants in Tehranand Ahvaz (20, 21).

Hence, the stabilization of this sludge before reusing or disposal should be considered seriously. In the first step, for lime stabilization of sludge, 0.2 g of slacked lime was added per each gram of dry solids. In this step, pH was higher than 12 for 5 days and FC was lower than 1000 per gram of dry solids until the 42ndday. For holding longer the pH over than 12, dose of lime was increased to 0.25 lime (g)/DS (g) in the second step. In this step, pH remained higher than 12 for 35 days and fecal coliform remained under 1000/ g of dry solids for 43 days. For eliminating the mentioned problem, 0.35 g of slacked lime was added per gram of dry solids. At this step, pH did not drop below 12 and also fecal coliform did not rise after 45 days. To decrease the dose of added lime in the 4th step, 0.30 g of lime was aggravated per each gram of dry solids. In this step, pH did not fall below 12 and FC did not rise after 45 days. As presented in Figure 2 and 3, in the lime addition reactor, pH and removal efficiency of fecal coliform enhanced with raising the lime dose from 0.2 to 0.35 lime (g)/DS (g). Nevertheless, based on our findings, there is no meaningful differencebetween 0.35 and 0.30 lime (g)/DS (g). Hence, 0.3 lime/DS can be considered as an optimal proportion of lime adding for stabilization of waste sludge of Shoosh wastewater treatment plant.

In order to be effective, lime stabilization must achieve a pH of 12 for at least 2 hours. This treatment leads to 3 to 6 log reduction of bacterial indicators. The findings of Placha et al. showed that after the lime hydrated addition the pH of mixture increased to 12.12 ± 0.02, and the Salmonella spp, strain was devitalized in 60 minutes (22). Jepsen et al. compared the effects of three processes of pathogenic bacteria reduction: lime hydrated stabilization, aerobic thermophilic stabilization, and composting method. During lime hydrated stabilization pH values of about 12.3 were reached, and indicator microorganisms were devitalized during 24 hours after lime addition (23).The findings of microbiological examination revealed that lime-stabilized sludge might be classified in class B of USEPA category in the most excellent circumstances. Based on the studies performed by Christie et al. and Lim et al. the stabilized sludge could be constructively used again as a cover up matter in landfill, recondition of poor soil, co-composting compounds and also in the cement industry (1, 13, 24).

If fertilizer consumption of waste sludge were considered, the microbiological quality of the product must be enhanced up to class A of USEPA criteria (20, 25-29). Upgrading the management of waste sludge is a fundamental step for the expansion of an integrated approach for the management of wastewater. Raw and treated sludge has been previously employed for agricultural and horticultural purposes for many years as it characterizes a resource of nutrients for growth of plant and also a competent soil conditioner improving particular physical characteristics of soil.

In this work, addition of lime in waste sludge was studied as another procedure for stabilization of municipal waste sludge. Addition of lime resulted in the raising of pH, ranging from 8 up to 12. Furthermore, addition of lime to raw waste sludge increased the content of total solids from 15% in the raw waste sludge to 50%, whereas the portion of organic matter of solids reduced from 72% to values ranging from 30% to 50%. In addition, the results of this study showed that sewage sludge stabilization with hydrated lime decreased fecal coliforms more than 99.99%,stabilized sludge, and covered standards of class B of USEPA criteria.