1. Background

The X-band frequency range (8 - 12.5 GHz), which is a part of electromagnetic waves, has various applications (1), such as satellite communications, radar, navigation, air traffic control, marine functions, and weather stations. Therefore, many workers are exposed to these waves in the workplace (2). In addition, microwaves can cause disturbances, inappropriate performance, and electromagnetic interference in electrical and electronic equipment (3, 4). Therefore, it is highly recommended that equipment be protected against microwaves, particularly in the aerospace, aviation, electronics, and military industries (5-7). Our previous study showed that radar frequency has adverse health effects, including the following thermal and non-thermal effects: reproductive effects, cancers, blood effects, genetic, adverse immune effects, mental effects, and oxidative stress (8). Therefore, it is necessary to protect workers from these effects. Compliance with permissible exposure limits, reduced exposure, and shielding are some of the methods used to protect workers (8). In occupational health, interposing shielding as an engineering measure is a priority in preventing adverse health effects caused by radiation. Thus, shielding is a superior method for the prevention of microwave exposure (1). Previously, limited shields, such as metal sheet and metal wire mesh, were used to reduce the intensity of microwaves in the workplaces to protect workers against microwave radiation (1, 9).

However, metal shields provide satisfactory shielding only at lower frequencies (10). Moreover, these shields have various problems, such as heavy weight, high cost, and low resistance to corrosion (11, 12). Therefore, to solve these problems, other materials should be investigated for their potential use as alternative occupational radiation shields and for the provision of variety in the engineering controls microwave radiation in the workplace.

Polymers have recently received significant attention because of their electromagnetic interference shielding and electromagnetic compatibility. Previous studies found that conductive polymers, such as poly (aniline) (13), polyaniline-polyurethane composite (14), polypyrrole/polyester composites (15), polypyrrole films (16), and polyaniline-polyurethane composite (17), protected electrical devices against electromagnetic interference.

However, conductive polymers have few large-scale applications because of their poor process ability (18), mechanical weakness, and chemical instability (19, 20).

Epoxy resins are popular thermosetting polymer matrixes that have excellent mechanical properties, chemical and heat stability, antibacterial properties, low contractibility, strong adherence (21), good dielectric constant, excellent electrical characteristics, low shrinkage, mechanical and chemical resistance, and favorable strength-to-weight (22). Therefore, this study was carried out to investigate the efficacy of these properties and determine the efficacy of net epoxy resin as an electromagnetic shield against radiation (x-band frequency range) in the workplace.

2. Objectives

This study aims to determine the efficacy of net epoxy resin in occupational radiation protection and investigate its electromagnetic shielding behavior, including shielding effectiveness, reflection, and absorption loss in the X-band frequency range.

3. Materials and Methods

3.1. Preparation of Epoxy Plates

This study used a two-component epoxy thermosetting resin: EI-403 as the epoxy (based on epoxy bisphenol A) and HA-14 as the curing agent (Polyamido Amine Immadozolin Hardener) (Mokarrar engineering material Co., Iran). Viscosity and density (at 25°C) were 720 centipoise and 1.04 gr/cm3, respectively.

The samples were fabricated according to the manufacturer’s instructions at a weight ratio of 100: 10 (ratio of epoxy to curing agent). The samples were made in three different thicknesses (2, 4, and 6 mm) and in triplicate with the dimension of 3 cm × 3 cm. The fabrication procedure is summarized as follows:

1. Add epoxy resin into the glass beaker.

2. Add curing agent.

3. Mix mechanically for 1 minute at 700 RPM

4. Submerge in ultrasonic bath for 8 minutes.

5. Remove bubbles in a vacuum drying oven (DZF-6024, China) for 8 minutes.

6. Pour the mixture into the silicone mold.

7. Keep the molds on a balanced desk at room temperature (21°C - 23°C) for 7 days.

After the seventh day, all samples (9 samples: three samples of each thickness) were removed from the silicone molds.

3.2. Electromagnetic Properties Characterization

Shielding effectiveness (SE) in the X-band frequency range (8 - 12.5 GHz) was measured (three times for each thickness) using a set-up that included the following: an Agilent 8510C vector network analyzer, Agilent 8514B S-parameter test set, and two coaxial to waveguide adapters. Full two-port calibration was carried out using an 85052B calibration kit.

3.3. Scattering Parameters

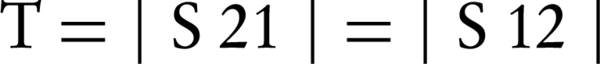

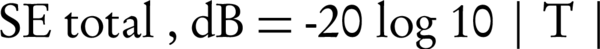

Microwave SE is determined by the logarithm of the ratio of the transmitted power when there is no shield (PI) to the power when there is a shield (PT) in a unit of dB (3, 14). Because it is difficult to measure the electromagnetic properties directly, SE can be expressed in terms of scattering parameters (S-parameters). In a waveguide, a radiated wave undergoes shielding (reflection, absorption, and transmission) when the incident wave at a point (port i) passes another point (port j); the scattering values of these waves are expressed as Sji. For example, S21 is the energy acquisition at port 2, having originated in port 1. Therefore, the scattering parameters S11 and S21 designate the amount of reflected energy and transmitted energy, respectively. In the present study, the S-parameters were obtained from an SE test at room temperature and humidity conditions (23), and the total SE value was calculated using the following equation (10, 24):

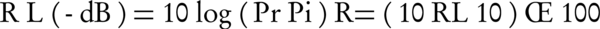

Where |S21| and |S12| are the amounts of transmitting energy, and T is the transmitted power density. In this study, SE was directly given experimentally using the S-parameters determined by the vector network analyzer. The input power used for all tests was 10 dBm, corresponding to 10 mw. During the SE measurements, the reflected radiation (Return Loss or S11 parameter) was measured and calculated according to Equation 3, and the absorption term (%) was obtained by Equation 4.

4. Results

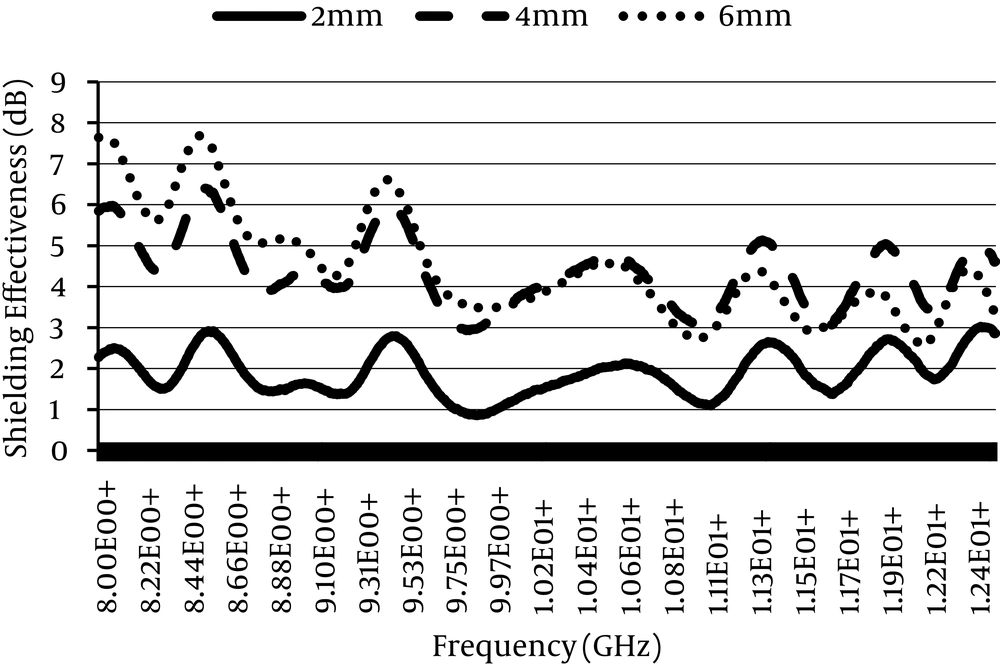

This study aimed to investigate the efficacy of net epoxy resin in electromagnetic shielding in the X-band frequency. Figure 1 shows a comparison of the SE values of different thicknesses of epoxy plates in the X-band frequency. The results showed that the SE values were increased when the thicknesses were increased up to 10.056 GHz. However, these results were not obtained in frequencies from 10.056 to 12.5 GHz. In this frequency range (10.056-12. GHz), the sample at 4 mm thickness had higher SE values than the sample at 6 mm thickness.

Figure 1 shows a similar SE variation in the X-band frequencies at each thickness. Based on this pattern, X-band frequency was divided into three sections: lower section (8 - 9.5 GHz); middle section (9.6 - 11 GHz); and upper section (11.1 - 12.5 GHz). Table 1 shows that the 6 mm epoxy thick plate had the highest average shielding effectiveness, and the 2 mm epoxy thick plate had the lowest average shielding effectiveness in the X-band frequency range that are 4.48 dB and 1.90 dB, respectively. The results also showed that the maximum SE value (7.68 dB) was at 6 mm, which occurred at 8.52 GHz, and the minimum SE value (0.86 dB) was about 2 mm at 9.9 GHz.

| Thickness, mm | X-band Frequency Range (8 - 12.5 GHz) | Lower Section (8 - 9.5 GHz) | Middle Section (9.6 - 11 GHz) | Upper Section (11.1 - 12.5 GHz) |

|---|---|---|---|---|

| SE Average ± SD (dB) | ||||

| 2 | 1.90 ± 0.41 | 2.02 ± 0.50 | 1.52 ± 0.40 | 2.17 ± 0.48 |

| 4 | 4.35 ± 0.88 | 4.97 ± 0.79 | 3.82 ± 0.59 | 4.22 ± 0.64 |

| 6 | 4.48 ± 3.03 | 5.92 ± 1.01 | 3.81 ± 0.57 | 3.55 ± 0.53 |

Table 1 also presents the SE values in the triple section of the X-band frequency for each thickness. In the lower section, the SE values for 2, 4, and 6 mm were 2.02 dB, 4.97 dB, and 5.92 dB, respectively. This table shows that the 6-mm thickness obtained the highest attenuation value among all thicknesses in the lower section of the X-band frequency. Therefore, in the lower section, the SE value increased by increasing the thicknesses of the samples. In the middle section, the SE value increased up to 4 mm and then stabilized. In the upper section, the SE value increased up to 4 mm and then decreased slightly.

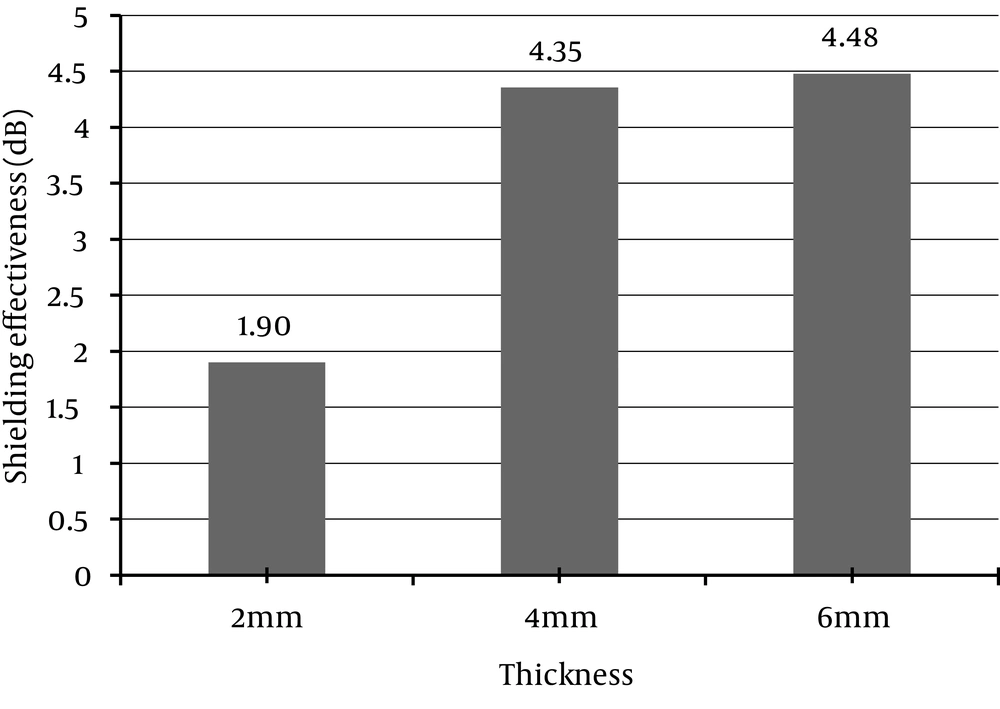

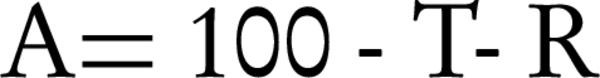

Figure 2 demonstrates the shielding effectiveness. Increases in thickness as a function of epoxy plate thickness. Increase in thickness from 2 to 4 mm led to sharp increases in the SE values (1.90 dB increased to 4.35 dB). However, in the 6-mm thick epoxy plate, the SE value did not increase noticeably (4.48 dB), compared to the 4-mm thick epoxy plate. In order to find the contributions of absorption and reflection loss to the overall shielding effectiveness of the epoxy plates, the s-parameters that were collected from the electromagnetic shielding characterization set-up were analyzed as percentages.

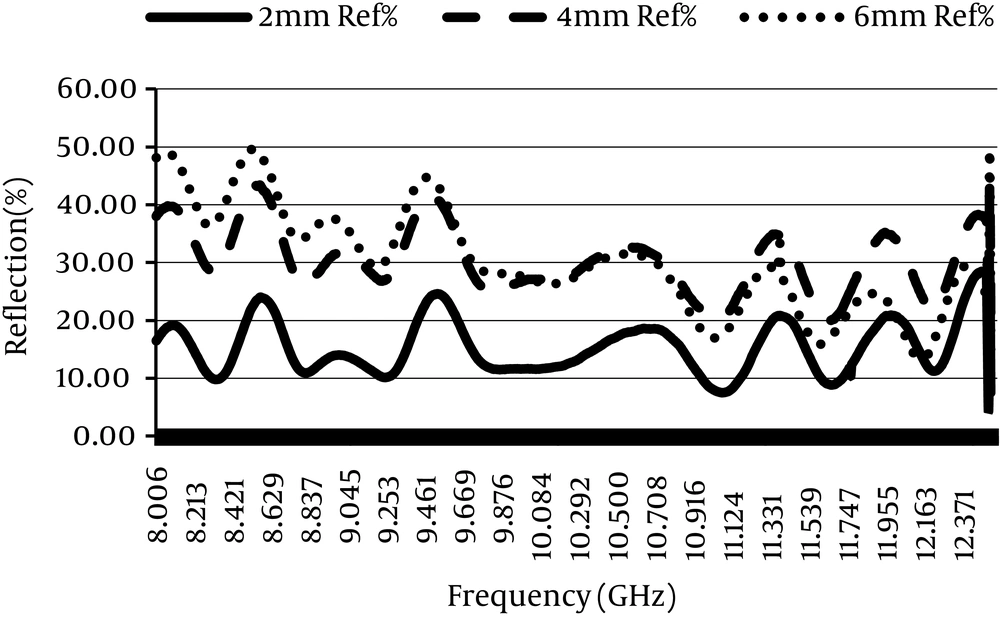

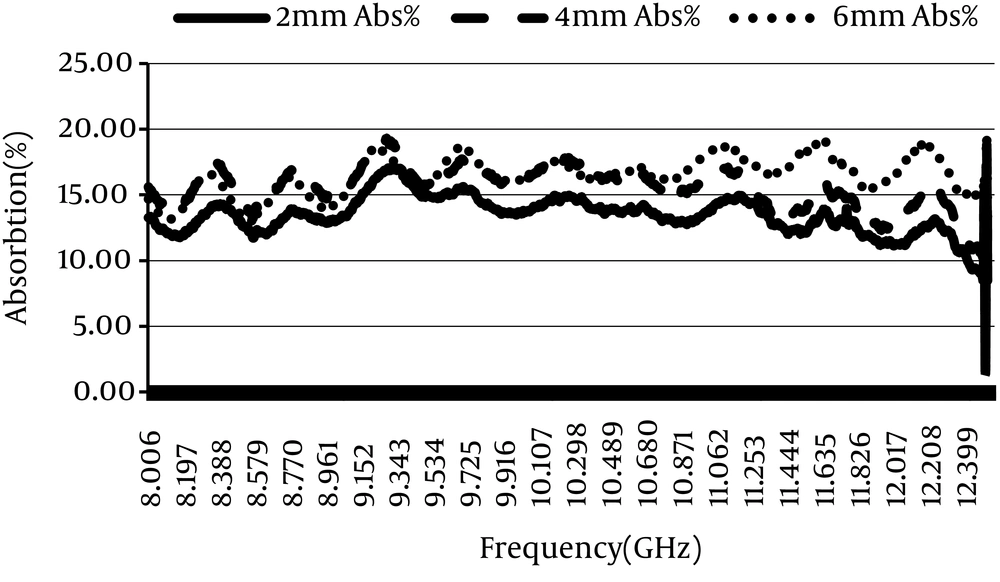

Figures 3 and 4 show the reflection and absorption loss in different thicknesses of epoxy plates in the X-band frequency range. The figures show that the amount of incident energy of radiation that was blocked by reflection increased with increased shielding plate thickness in the lower section of the X-band frequency. However, the amount of incident energy of radiation that was blocked by absorption increased with increases in shielding plate thickness in the upper section of the X-band frequency. Figures 3 and 4 also graphically illustrate that the variations in absorption values were lower than in the reflection values. Shielding by reflection from 7.49% to 49.63% of the overall shielding. However, shielding by absorption was from 8.48% to 19.30%.

| 2 mm | 4 mm | 6 mm | 2 mm | 4 mm | 6 mm | 2 mm | 4 mm | 6 mm | |

|---|---|---|---|---|---|---|---|---|---|

| Contributions | Reflection | Absorption | Transmission | ||||||

| Average ± SD | 15.36 ± 4.57 | 30.37 ± 5.52 | 30.2 ± 8.99 | 13.46 ± 1.40 | 15.53 ± 1.60 | 16.44 ± 1.43 | 71.18 ± 4.16 | 54.11 ± 5.20 | 53.37 ± 7.97 |

| Max | 28.46 | 43.4 | 49.63 (at 8.528 GHz) | 17.04 | 19.30 (at 9.287 GHz) | 19.23 | 78.48 | 68.4 | 68.16 |

| Min | 7.49 | 20 | 13.4 | 8.48 | 10.2 | 12.87 | 60.55 | 42.9 | 37.01 |

The results showed that variations in reflection values were higher than the absorption values (Table 2). Table 2 also lists the contributions of reflection and absorption to the overall SE of epoxy resin as a function of shielding plate thickness. The SE values reported in this tabulation are the average values in the X-band frequency range. The tabulation shows that the reflection values of each thickness of epoxy plate were 15.36%, 30.37%, and 30.2%, respectively. The absorption values were 13.36%, 15.53%, and 16.44%, respectively. Thus, the shielding value by absorption slightly increased as the thicknesses of the shielding plates increased. However, the shielding value by reflection sharply increased from 2 mm to 4 mm thicknesses and then stabilized at 6 mm thickness. The results in Table 2 also show that the amount of energy transmitted by the 4 mm and 6 mm epoxy thick plate were 54.11% and 53.37%, respectively.

These results indicated that the maximum amount of power that was blocked by reflection (49.63%) was in the epoxy plate 6 mm in thickness, which occurred at a frequency of 8.528 GHz. The maximum amount of power blocked by absorption (19.30%) was in the plate 4 mm thick, which occurred at a frequency of 9.287 GHz.

5. Discussion

This study investigated the efficacy of net epoxy resin in electromagnetic shielding in the X-band frequency range for the protection of workers against microwave radiation in the workplace. In addition, the study determined the amounts of reflection loss and absorption loss to the overall shielding effectiveness of the epoxy plates.

The results indicated that the SE values in the epoxy plates 2, 4, and 6 mm in thickness were 1.9, 4.35, and 4.48 dB, respectively (Figure 2). The findings showed that increase in epoxy plate thickness lead to increasing the SE values (Table 1). However, the SE value 6 mm epoxy thick plate was not noticeable. Therefore, it was determined that an increase in thickness was useful up to 4 mm (Figure 2, Table 1). Figure 1 showed the comparison of the SE values of different thicknesses in the X-band frequency. This figure indicated that the SE values in the 2-mm thick epoxy plate were less than other thicknesses. Unexpectedly, the SE values in the 6-mm epoxy thick plate were not higher than in the other thicknesses. But, this thickness had higher value only in the lower section of the X-band frequency range. Figure 2 also shows that there was a similar variation pattern in the shielding effectiveness of the three thicknesses. In other words, these thicknesses showed similar attenuation behavior in reducing the intensity of microwave radiation. Based on this pattern, the X-band frequency was divided into three sections: lower section (8 - 9.5 GHz); middle section (9.6 - 11 GHz); and upper section (11.1 - 12.5 GHz). The survey of these three sections demonstrated that with increasing the thickness, the SE values only increased in the lower section of the X-band frequency. In the middle section, the SE value increased up to 4 mm and then stabilized. However, in upper section, the SE value increased up to 4 mm thickness and then decreased slightly (Table 1).

The knowledge of the SE values in each of the three sections could be useful in selecting the proper thickness of the epoxy plate used in microwave shielding. The literature review did not provide similar studies that demonstrated an attenuation pattern in microwave by the shielding material. This was another limitation for our study.

The findings showed the amounts of reflected and absorbed radiation energy in different thicknesses of epoxy plates in the X-band frequency range (Figures 3 - 4). The averages of shielding effectiveness by reflection were 15.36%, 30.37%, and 30.2% in epoxy plates 2, 4, and 6 mm epoxy thick plates, respectively. The results clearly showed that shielding by reflection was higher than by absorption. These figures graphically illustrated that the variation of absorption values is lower than that of the reflection values.

Kuzhir et al. (2011) reported a comparative study of the electromagnetic interference shielding of nanocarbon dispersed in epoxy resin at low concentration (0.5 wt. %) to solve electromagnetic compatibility problem in electronic devices. The average thickness of the samples was as follows: 0.750 mm for MWNT /resin; 0.678 for SWNT /resin; 0.685 for CB /resin; and 0.686 for net resin. The overall shielding effectiveness of the samples was 14.88% for SWNT/resin, 8.79% for MWNT/resin, 4.49% for CB/resin, and 4.49% for net resin in the X-band frequency range. These findings showed the shielding effectiveness achieved in the net resin samples was 2.95% by reflection and 1.54% by absorption (25). The results demonstrated that reflection was the main mechanism in overall shielding effectiveness in net epoxy resin. Our findings confirmed these results with respect to the contribution of reflection and absorption energy to the overall SE of epoxy plates (Table 2).

A noticeable finding was that absorption loss was a function of the product µrσr, whereas the reflection loss was a function of the ratio σr/µr, where σr is the electrical conductivity relative to copper, and µr is the magnetic permeability relative to free space (26, 27). In the present study, reflection was the main mechanism in overall shielding effectiveness, which indicates that in the samples used, relative conductivity was greater than the relative permeability. Equation 5 found that conductivity was a function of angular frequency and the imaginary part of permittivity (ε*=ε'-iε''):

Where ε0 is the permittivity of free space and ω (2πf) is angular frequency.

Magnetic permeability and the dielectric constant are two main factors in electromagnetic shielding (26, 27). The findings showed that in the present study, the main factors in the increased reflection loss were frequency and the dielectric loss in the epoxy plates (28, 29). Figure 3 shows the effects of frequency. This illustration shows that the reflection differed from the changes in frequency range.

The findings showed that the dielectric constant was more important than magnetic permeability in the net resin epoxy plates, which were the lossy dielectric medium in our study. A lossy dielectric is a medium in which electromagnetic radiation loses power as it propagates because of poor conduction. In other words, a lossy dielectric is a partially conducting medium (imperfect dielectric or imperfect conductor) where σ ≠ 0, which is distinct from a lossless dielectric (perfect or good dielectric) in which σ = 0. However, a line of demarcation between a good conductor and a lossy dielectric is not easy to draw (30). In our study, the epoxy thick plates showed a good dielectric constant because tan θ was very small or σ≪ωε (30). Based on these findings, the dielectric loss of the epoxy plates and frequency were the main factors in the increased reflection loss in this study (28, 29).

In addition, the results of the present study showed that the amount of incident radiation energy blocked by reflection increased with increases in shielding plate thickness at the lower section of the X-band frequency. However, the amount of incident radiation energy blocked by absorption increased with increases in shielding plate thickness in the upper section of the X-band frequency. The literature review did not obtain a previous study that indicated reflection and absorption values in different sections of the X-band frequency. In addition, the findings showed the maximum amount of power that was blocked by reflection and absorption occurred in the lower section of the X-band frequency. This finding could be useful in obtaining the proper shielding at that specific frequency.

As shown in Table 2, the amount of transmitted energy in the 4- and 6-mm thick epoxy plates indicates that these thicknesses were nearly a half-value layer. Therefore, these plates could be applied as a half-value thickness to reduce the incident energy in the X-band frequency by approximately 50%. The half value layer (HVL) is defined as the thickness of a shield or an absorber that reduces the radiation level by a factor of 2, that is, to half the initial level (1).

It is well known that the basic principles of radiation protection are time, distance, and shielding (31). Shielding is an engineering control method.

The ICNIRP noted that protective measures for workers include engineering and administrative controls, personal protection programs, and medical surveillance. Appropriate protective measures must be implemented when exposure in the workplace exceeds the basic restrictions. In the first step, engineering controls should be undertaken wherever possible to reduce the device emissions of the fields to acceptable levels (32). Limited studies were found about shielding design or provision for microwave radiation in the workplace (9). The most protective measures found for controlling non-ionizing radiation exposure at high frequency were administrative controls (32-41).

The recommended exposure limit (10 mw/cm2 for 10 MHz to 100 GHz, averaged over any 6-minute period) is the only administrative protection measure that has been established by several international and professional organizations and regulatory agencies (OSHA, ANSI, IEEE, and ICNIRP) (1, 8, 42-45).

The present study showed that the epoxy plate could be introduced as an alternative material for microwave shielding. This result could obtain a variety in the engineering controls for microwave protection in the workplace.

This study investigated the efficacy of net epoxy resin in electromagnetic shielding in the X-band frequency in the workplace. The results showed that the 6-mm thick epoxy plate had an attenuation value of 4.48 dB. This thickness was ideal for shielding effectiveness at 8.52 GHz with 7.68 dB, as shielding effectiveness. The findings showed that by increasing the thickness, the SE values were increased. However, the 4-mm thick epoxy plate provided sufficient shielding and economic benefits. Therefore, this thickness is recommended for shielding application in X-band frequency. However, the 6-mm thick epoxy plate is recommended in the lower section, This study indicated that epoxy plates could be applied to reduce the exposure to X-band frequencies and increase the range of engineering controls for non-ionizing radiation protection in the workplace. In addition, this study found that reflection was the main mechanism in overall shielding effectiveness. Compared with other polymers and polymer nanocomposites, epoxy is inexpensive, easily processed, and plentiful. Appropriate electromagnetic shielding could be provided by net epoxy resin without the cost of preparing nanomaterials, dispersion, or composite characterization. Therefore, epoxy resin could be a suitable candidate for shielding applications in the workplace. It is suggested that in future studies, the improvement of the shielding effectiveness of epoxy resin at lower thicknesses be conducted.