1. Background

One of the risks that constantly threaten various industries, especially oil and gas industries is the accidents of fire and explosion. Chemical industries, especially the ones which transport, process, and storage the hydrocarbon materials are potentially at risk of fire and explosion, and various damages caused by the fire. It can cause human fatalities, serious injuries, financial losses due to damage of equipment, and disruption of productive activity, loss of employment, and sometimes irreparable damage to the environment, and also other costs such as insurance premiums would increase (1). Hence, identification of danger factors and the ways of controlling them especially in chemical, oil and natural gas industries are very important. Accordingly, 15 to 30 percent of the capital cost is typically spent on safety and prevention of pollution in the oil and gas industries (2). Special Petrochemical Economic Zones is one of the Iran’s most important economic hubs. Thus, preserving and protecting these industries and its powerful work forces are crucial. On the other hand, by increasing chemicals transport by pipeline, the number of pipeline accidents is increasing each year. According to the data of the U.S Office of Pipeline Safety (OPS), the rate of accidents has increased about four percent annually (3). The area under investigation of this study in Special Petrochemical Economic Zones has more than 60 pipeline connections (feed-products). These contain chemicals such as chlorine, ammonia, Butadiene, Benzene, sour gas, and etc., are spread upon the supports on the ground in most parts, many of them are located next to each other. This sometimes makes the diagnosis of the pipes which are used for welding operations, cutting and other operations very difficult, leading to outbreak of an accident. On this basis, threatening pipelines can cause various problems such as third-party harm, problems related to improper design, improper performance, and corrosion pipelines; which can cause devastating events (4). Hence, it is essential to recognize the dangers of petrochemicals and pipeline units, and provide and implement solutions to reduce the risks and prevent the possible accidents that may lead to both life and economic losses. This research examined the economic impacts of chemical materials release, in one of the Special Petrochemical Economic Zones. However, the Quantification and applying a specific technique for estimation of financial damages is rarely used in Iran. Besides, the estimation of insurance is usually performed by foreign companies. Thus, the findings of this study can be used to determine the losses due to fire and explosion at a chemical industry, and can be also used as insurance premium.

2. Objectives

In this regard, risk indices use the numerical values to classify various parts of an industrial fire and explosion hazard, and identify the areas with high levels of danger. Quantification of danger can also help to estimate the losses, so that due to the above information, it is possible to estimate the losses of the fire in each specific sector (5).

3. Materials and Methods

Among the most important hazard indices are the Instantaneous Fractional Annual loss Index (IFAL), the fire and explosion index (MOND), and the Fire and Explosion Index of DOW (F & EI) (6, 7).

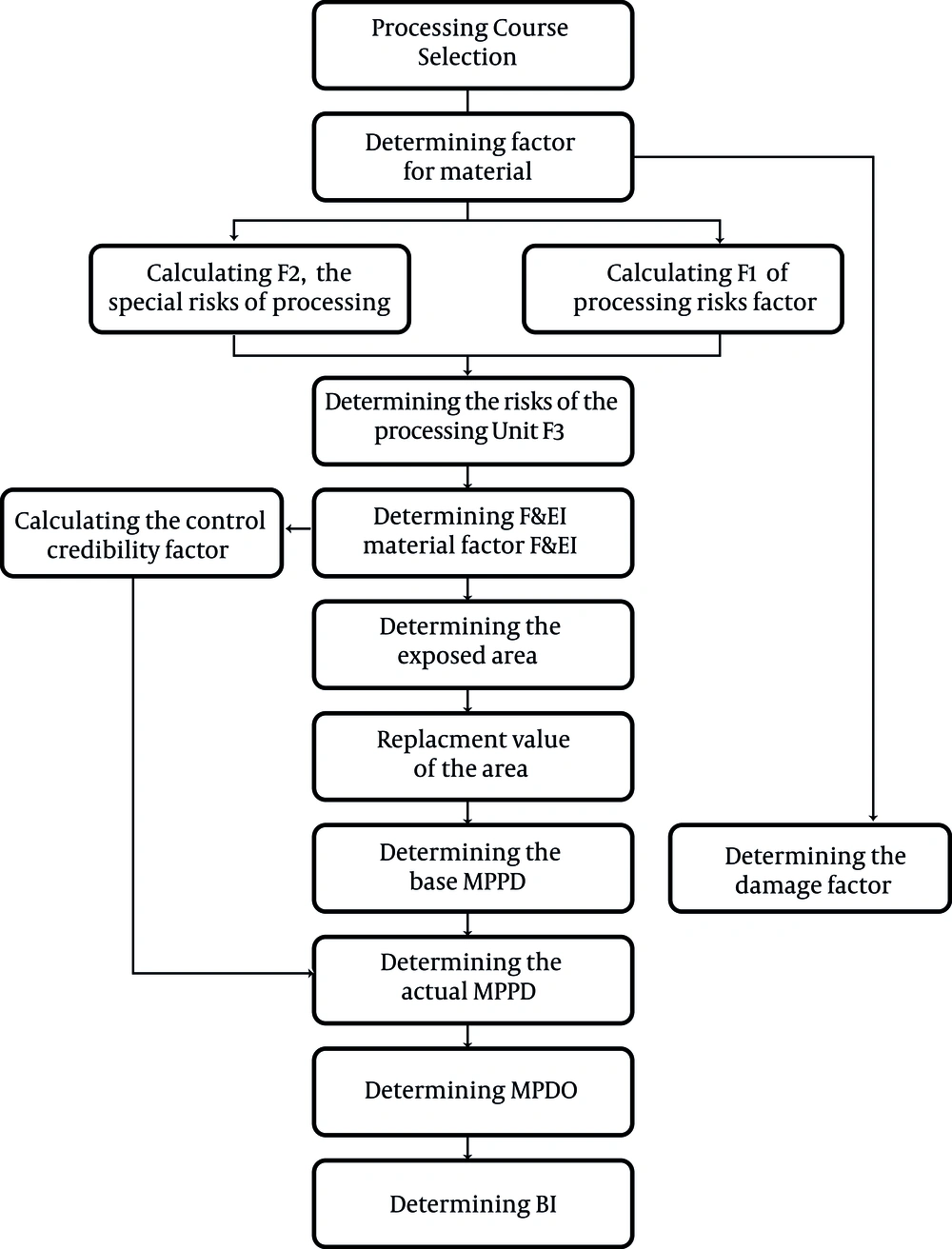

Dows’ Fire and Explosion Index is one of the most reliable indices to identify the potential occurrence of fire and explosion (8). One of the specifications of this index is assessment of risk in chemical materials processing units and storage of these materials, and estimation of the costs in money. In addition, it is the only index which takes into account all the safety parameters, and is able to select the important parts of the process associated with the hazard. Besides, it is able to calculate the value of failures and loss by using the daily working pauses, the contingent value, production value, and also the failed equipment in money. The above index can also provide a guideline for insurance companies to determine premiums (9). This index has been used in many researches across the world. Among those are the studies of Gupta et al. (1997), Roy et al. (2003), Bernatik and Libisova (2004), and Suardin et al. (2007) (9-12). These researches showed that this index has been used for different purposes such as rating and classifying the danger, determining the economic impacts, and designing safe processing industries too. Suardin et al. concluded that by applying the (F&EI) index, it is possible to design safer and more economical reactor and distillation system. This index has been also used in a number of studies in Iran, especially in the chemical industries. The researches of Jafari et al. (2012) and also Ahmadi et al. (2011) are some examples (13,14). The process of Fire and Explosion Index calculation is shown in Figure 1. Based on this Figure, after selecting a network of petrochemical pipelines, to assess the potential chemical energy (Materials Factor (MF)) all the chemical materials in the pipelines were identified. Then the pipelines containing chemical materials with the highest Material Factor (kg/h) and their economic values were compared, and the most important pipeline was chosen to calculate the fire and explosion index. At the first stage, the common dangers of the pipeline (F1) were determined based on the following factors: Exothermic chemical reaction-endothermic processes, handling and transferring materials–an indoor or enclosed process unit, accessibility, controlling leaks and releasing chemicals. In the next stage, specific dangers of the pipeline (F2) were calculated according to the following factors: Toxic substances, atmospheric pressure (less than 500 mm Hg), Operation within the flammable range, explosive dust, pressure, low temperature, the proportion of flammable / unstable substance ,corrosion, or erosion, leaks, hoses and junctions, using combustion equipment, hot oil heat exchange system and Rotating Equipment.

| Grade of Risk | F&EI Index Range |

|---|---|

| Light | 1 - 60 |

| Milda | 61 - 96 |

| Medium | 97 - 127 |

| Heavy | 128 - 158 |

| Sharp high | Above 159 |

Risk Grade of F&EI

After calculating the general and specific dangers of pipelines, pipeline danger factor (F3) was calculated by using equation:

F3 = F1× F2

By calculating the factor of pipeline risk and the materials factor, fire indicator and explosion (F&EI) were calculated by using the equation:

F&EI = F3×MF

The grade of risk was determined by the Table 1. The radius of exposure was also calculated by using equation:

Y = 0.84 X

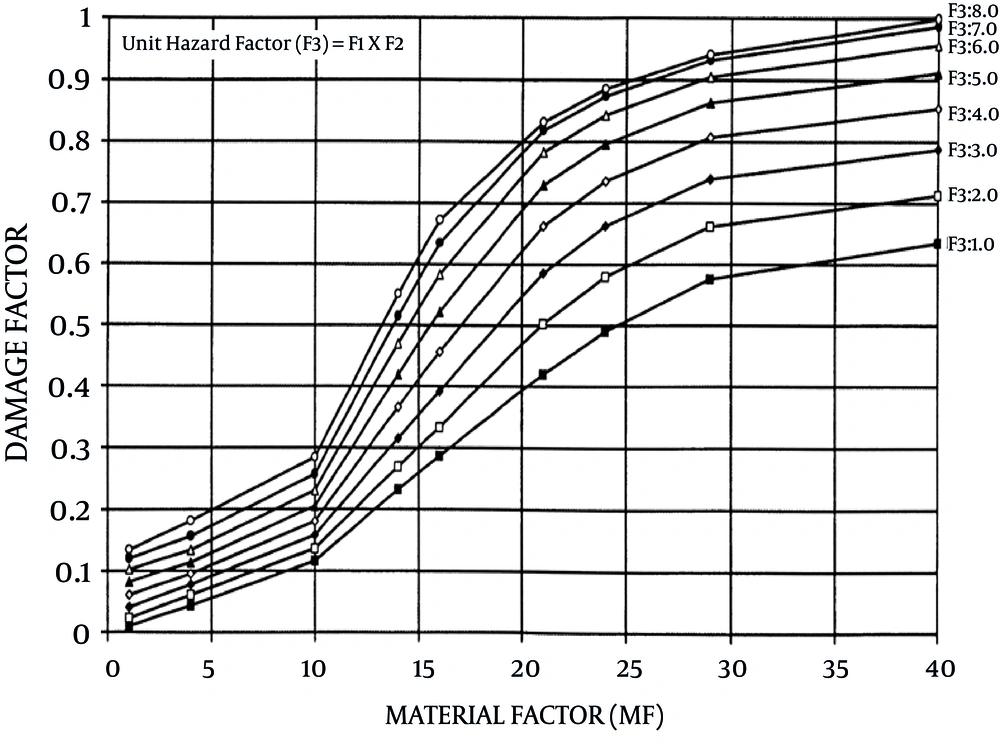

Where Y is the radius of exposure for foot, and X is the index of F&EI. The calculation of the values of the exposed area of this research were based on the estimated value of the chemicals released within 15 minutes after the releasing time, the cost of redesigning, and reinstalling the pipelines in the area of exposure. Factor of damaged materials, products and equipment which were in the area of exposure were determined by the factor of materials and the risk factors of processing unit Figure 2.

After determining the factor of damage and the value of exposure zone, the maximum possible damage of the property (base MPPD), was calculated by multiplication of those two factors. Since, the base MPPD does not include the proceedings taken to control the damage and losses, to determine the actual maximum possible damage (actual MPPD), the Loss Control Credit Factor (LCCF) was determined. LCCF was calculated by the equation:

LCCF = C1 × C2 × C3

The processing credibility controlling factor, (C1) is based on the state of emergency proceedings, coolers, explosion control, emergency pause of processing, computer controlling, inert gases, guidelines, and operational procedures, programs related to chemicals and reactive materials, and other programs related to the analysis of risk processing. The materials isolation factor (C2) was calculated by the valves remote control, the temporary storage and neutralization tanks, drainage, and also computer controlling. To determine the factor of fire protection (C3) the following factors were checked including: Leak detection, strength of steel structure, source of water sustenance fire systems, proprietary quench system, sprinkler system, water spray curtains and covers, Foam, monitors and hand-held fire capsules, and protection of cables. The actual amount of the maximum possible damage to the property was estimated by using the equation:

MPPD (actual) = LCCF× MPPD (base)

After calculating the actual maximum possible damage to properties, the maximum probable day Outage (MPDO) was determined, and the economic disruption caused by fire and explosion of chemicals (Business Interruption, BI) was calculated by using equation 6: BI is the economic disruption caused by the failure of the systems, and VPM is the Value of Production per Month (15).

4. Results

The results of material factor (MF) analysis for 47 available chemicals in petrochemical pipelines illustrated in Table 2, show that Butadiene, ethylene vinyl acetate, and the epichlorohydrin with the material factor of 24 has the highest material factors among all of the studied pipelines. Examining the discharge rate of chemicals passing through the pipelines demonstrates that, the discharge rate of Butadiene pipeline with 300 thousand kilograms per hour had the highest transition rate among all other chemicals in the region, So, for toxicity, fire and explosion, Butadiene Pipeline was recognized as the most dangerous pipeline in the region. Therefore, it was then considered as the most important line for more analysis. These findings are similar to the results of a number of other relevant conducted studies which also indicated the high chemical exposure of Butadiene compared to other lines. As for instance, the results of a research on selected pipelines conducted by Jabbari et al. (2008) among others, showed that Butadiene with Chemical Exposure Index (CEI), of 1000 had the highest chemical exposure index among all other existing pipelines in the region (16). After selecting Butadiene pipeline, the hazard factor was determined by F&EI index, and the confine exposed area was calculated. According to the F&EI index value of 161.5 in Table 2 it can be indicated that Butadiene pipeline had the highest grade of risk (as mentioned in Table 1, i.e. sharp high). The equipment damage factor in the exposure area was about 0.87. Therefore, since the damage factor is high, which is induced by fusion of Butadiene pipeline, the possibility of release of chemicals and the subsequent damages of equipment is up to %87. On the other hand, the results confirm that the fusion of Butadiene line and its explosion can cause damage to the other equipment in the vicinity of radius 41.5 m (Table 2). Therefore, to study its economic impacts and calculating the maximum possible damage of the property (base MPPD), the value of the products beside the Butadiene pipeline and the investment designing, implementing and supervision of the operations of the pipelines were calculated.

| The Cases | The Results |

|---|---|

| Materials factor | 24 |

| Common processing hazard (F1) | 1.95 |

| Specific processing hazard factor (F2) | 3.45 |

| The hazard factor of processing unit (F3) | 6.73 |

| F&EI index | 161.5 |

| Exposure radius | 41.5 m |

| The area of exposure | 5410 m2 |

| The damage factor | 0.87 |

The Results of Calculating F&EI Index, and the Confine Exposed Region for Butadiene Pipeline

Based on our findings, the value of the chemicals products in the area for 15 minutes of release is about 300 thousand dollars. The cost of redesigning, and reinstalling the pipelines in the exposure area is about 4.93 million dollars. So the value of the exposure area is 4.87 million dollars, and the base maximum possible property damage (base MPPD) would be about 4.24 million dollars. Based on the calculations, the Loss Control Credit Factor (LCCF) was computed and determined about 0.92. The actual MPPD is 3.9 million dollars and by more than 70% of confidence the probable duration of the system failure (MPDO) would be 80.16 days. Since most of the pipelines contain chemical products that are used as raw material and feedstock, the value of the produced output is more than the present value of the chemicals in the pipelines, so that the value of the produced output in the related petrochemical units is about 410 million dollars per month. Hence, the economic disruption caused by fire and explosion on of the pipeline would be at least 767 million dollars. However, as various studies have shown, the exact calculation of the economic consequences of the events of chemical processes is very difficult and complex. So, the results can be used as the minimum probable loss to determine the role and importance of the controlling actions for the possible accidents. The study of the various resources also shows that due to the extensive economic consequences resulted from the processing units’ accidents; the estimations performed by various agencies have different results for the same accidents. For example, based on Carroll, (2000), the losses caused by accident in France in 1992, were estimated 370 million U.S. dollars by the Major Hazardous Incident Data Service (MHIDAS), and 260 U.S. dollars by Marsh McLennan counsels (17, 18).

5. Discussion

Based on the findings of this study, Butadiene pipeline has the highest grade of risk, and appropriate control actions are required to reduce the risks. The results indicate that the damage factor of the equipment in the area is about 0.87. Therefore, since the damage factor is high, the possibility of release of chemicals and the subsequent damages of equipment is high, and up to 87 percent. The most likely actual damage is 3.9 million dollars, the number of lost working days due to fire and explosion is 80 days, and economic disruption due to the fire and explosion in the pipeline is at least 767 million dollars. On the other hand, considering the establishment of lines in an environment outside the petrochemical complexes, the possible damage by third party on them and the nearby equipment and its economic consequences are also high. Therefore, a comprehensive risk assessment and management, is highly essential and should be performed for different parts of the petrochemical pipelines.