1. Background

Noise, defined as ‘unwanted sound’, is perceived as an environmental stressor and annoyance. Recently, there has been a growing interest in noise control processes. Since the noise pollution has become a serious issue, the demand for a better environment and a more diversified lifestyle is increasing (1-3). The primary reason is that the exposure to high noise levels leads to adverse health outcomes. Noise pollution can affect the human life in several aspects, such as hearing problems, poor cognitive function, cardiovascular issues, sleep disturbances, troubled communication, and mental health problems (4).

Therefore, composite materials that are able to absorb sound energy over a broad temperature and frequency range are strongly desired. Sound absorption constitutes one of the major requirements for human comfort today. Polymers, due to their viscoelastic properties, have long been used as energy absorbing materials. Rubber and other polymers that have good damping capacity include polyvinyl acetate, polyurethane (PU), polymethylmethacrylate (PMMA), and polytetrafluoroethylene. A new class of polymers, Interpenetrating Polymer Networks or IPNs, has been reported to exhibit broadband damping properties (5).

Polyurethanes are one of the largest classes of polymers with properties that can be tailored over a wide range for a large number of applications. Polyurethanes are particularly well-known polymers with special properties varying from hard materials to soft elastomers (6). PU is formed from the polymerization between isocyanate and polyol having at least two reactive hydrogen atoms. However, the applications of PU are limited due to its low mechanical strength and poor thermal stability (7).

PMMA is a thermoplastic polymer that most nearly simulates glass’s transparency. The synthesis of PMMA is through the polymerization of methyl methacrylate (MMA) monomers that are joined with each other by adding an initiator. PMMA is a stiff, hard, and easy to polish compound with excellent solving and oil resistance properties. It has also a good optical and adhesive nature, but it is sensitive to stress and low temperature and is fragile (8).

The undesirable properties of pure polyurethane, including the absorption of mechanical energy in a narrow transition temperature range, as well as low mechanical and thermal resistance, can be improved by providing IPN. The rigidity and the heat stability of PU polymer will be obviously improved if PU is reclaimed by PMMA via interpenetrating a polymer network (IPN) (8). Due to fluent properties and simple synthesis of PU, it is one of the most widely used polymer components in the synthesis of IPNs (9, 10).

IPNs have better mechanical resistance such as polymer elasticity and polymer resistivity due to physical interlocking and inter-network interactions compared to cross-linked individual networks (11). IPNs can be defined as a mixture of two or more adjacent polymeric networks that can have partial or total physical interlocking between each other. In other words, they are a unique alloy of networked polymers, and it is not necessary for them to have covalent or graft bonds (12, 13). The first polymer forms a continuous phase and the second polymer fills the holes of the first polymeric network (14). IPNs are classified according to the four factors including chain synthesis, network structure, the nature of transverse couplings, and the type of mixing. IPNs can be formed simultaneously, sequentially, or by the latex technique (15).

Several studies have been conducted on the application and synthesis of IPNs. Many researchers have studied the PU IPNs to improve PU properties (10). Recently, Suthar et al. have studied a series of IPNs from castor oil based on PU with acrylic. They showed that the IPNs revealed good mechanical properties (16). Kumar et al. prepared a series of semi-interpenetrating polymer networks (SIPNs) of PU and PMMA in different weight ratios. These studies showed that IPNs are stable at temperatures up to 325°C (17).

Wang et al. prepared a series of PU/PMMA interpenetrating polymer networks (IPNs) by a sequential method and these IPNs had effective damping by the introduction of PU into EP to form IPNs (18).

In order for the damping factor to be effective in the temperature range and frequency of damping application, the dampening factor should exhibit a high tan δ value (tan δ of > 0.3) over a temperature range of at least 60 - 80°C (19, 20).

In this study, a sound absorbing material based on PU/PMMA IPNs were synthesized to give better sound absorption at an expanded frequency range, preferably with a minimum thickness. In addition, the mechanical property and morphology were also investigated in this study as the other important parameters in the fabrication of sound absorbing materials.

2. Objectives

The purpose of this study was to use PU with a low glass transition temperature and PMMA with a high-temperature Tg to form a new substance as a sound adsorbent that is able to absorb sound energy over a wide temperature and frequency range.

3. Methods

3.1. Raw Materials

The chemicals used in this study were polyoxytetramethylene glycol (PTMG) with a molecular weight of 2000 g and average functionality of 2 from Sigma Aldrich Co., (USA), toluene-2 4-diisocyanate (TDI, molecular weight of 174.2 g, average functionality of 2, Merk Co., Germany), Trimethylolpropane (TMP, molecular weight of 134 g, average functionality of 3, Merk Co., Germany), and 1,4 butanediol (1,4-BD; molecular weight of 92 g, used as the chain extender). Methyl methacrylate monomer, Ethylene dimethacrylate, and Benzoyl peroxide were obtained from Merck Company (Germany).

3.2. PU/PMMA IPN Synthesize

The purified MMA monomer and EDMA (1% of MMA) were mixed together with BPO initiator (0.15% of MMA) and stirred at room temperature for 5 min to form a homogeneous solution. Then, the temperature was raised to 78°C to dissolve the initiator (15).

The polyurethane prepolymer was prepared by fixing the molar ratio of the isocyanate (NCO) group to the OH group at 2.0/1.0. The PU network was obtained from the composition of PTMG and TDI with 1 equivalent of TMP -1.4 BD mixture (4:1 equivalent ratio) at 60°C in a nitrogen atmosphere for 30 minutes.

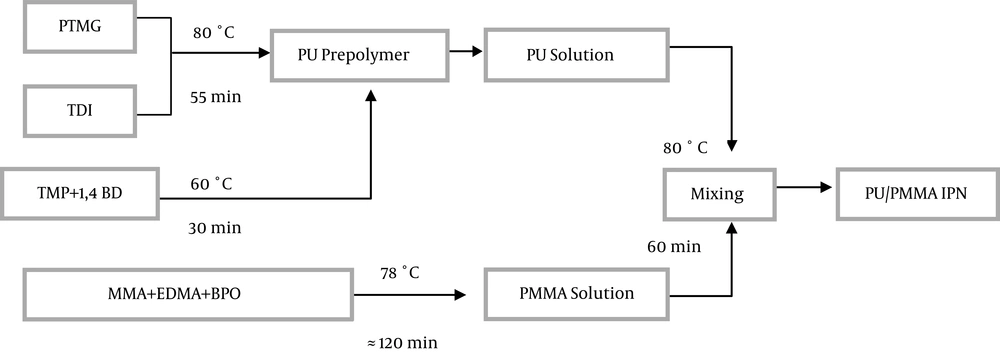

The MMA-EDMA-BPO with different ratios was added to a mixture of PU solutions. The mixture was mixed at ambient temperature for 20 minutes. The reaction then proceeded at 80 °C for 1 hour. After a few minutes, the mixture was quickly poured into a Teflon flask and placed in an oven at 55, 65, 85, and 110 °C for a final polymerization at 24 hours intervals (15). The PU/PMMA mass ratio in the IPN system was 85/15, 75/25, and 65/35. Thus, a series of IPNs by changing the ratios of PU to PMMA was prepared. The synthesis process of the PU/PMMA IPN is illustrated in Figure 1.

3.3. Characterization

The cell morphology of different IPNs was studied on the cross-sectional surfaces by scanning electron microscopy (VEGA\\ TESCAN, CZECH).

The synthesis and reaction of chemical groups in the system were determined by the infrared spectroscopy method. The FTIR of PU, PMMA, and PU/PMMA IPN was performed using the ATR (Attenuated Total Reflection) technique by an Equinox 55FTIR spectrophotometer (Bruker Co).

The dynamic mechanical analysis was used in the tension mode to study the thermal behavior and transfer properties of the samples, especially Tg by Tritec 2000 DMA (Triton Technology Co. England).

The experimental methods based on ISO -10534-2 were used to determine the Sound absorption coefficient (21). The sound absorption coefficient was measured using a BSWA impedance tube of SW422 series. The tube impedance device consisted of two tubes of 3 and 10 cm in diameter and samples were prepared according to the diameter of the tube impedance device. The larger tube was used at frequencies from 63 to 1600 Hz and smaller tubes at 800 to 6300 Hz. All specimens had a thickness of 1.5 cm. The presented data are the average of at least two sample measurements.

4. Results

4.1. FTIR Test

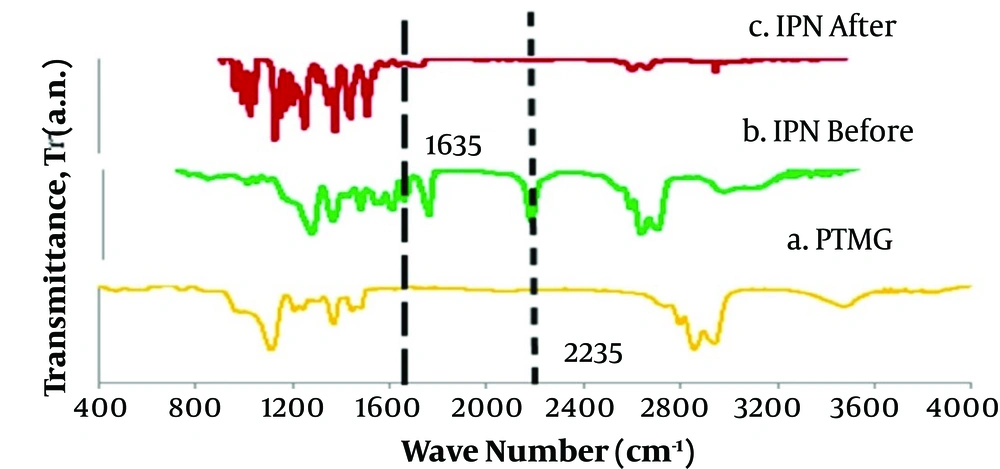

The FT-IR spectra of PTMG and PU/PMMA IPN before and after curing are shown in Figure 2. The FTIR spectra show the complete polymerization of PU and PMMA components.

4.2. Dynamic Mechanical Analysis (DMA)

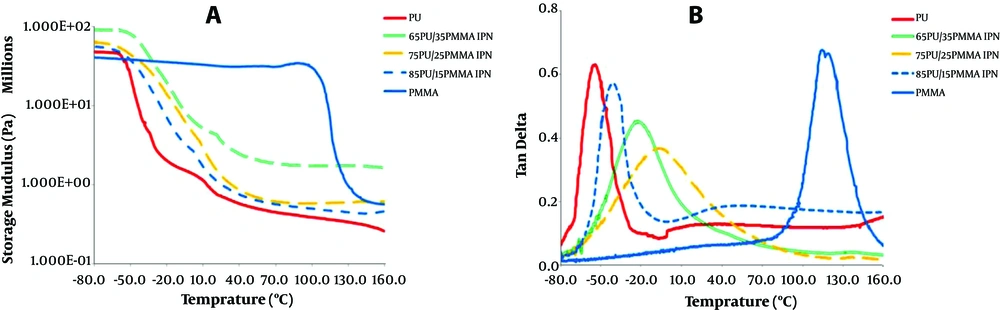

The morphology and interconnectivity of IPNs were investigated through the DMA test. Figure 3 shows the synthetic IPN damping properties with different ratios of PU to PMMA at a frequency of 1 Hz. The PU and PMMA curves are shown as the reference samples. In Figure 3, the storage modulus (E’) and loss factor (tan δ) are shown for different mass ratios of PU/PMMA in the prepared IPNs.

Considering the curves in Figure 3, the storage modulus (E’) for IPNs in the temperature range showed that all of the prepared IPNs had a higher modulus than the pure PU. Regarding the storage modulus of IPNs, it can be said that the 65/35 IPN had a higher storage modulus than the other prepared IPNs (21).

4.3. Sound Absorption Coefficient Analysis

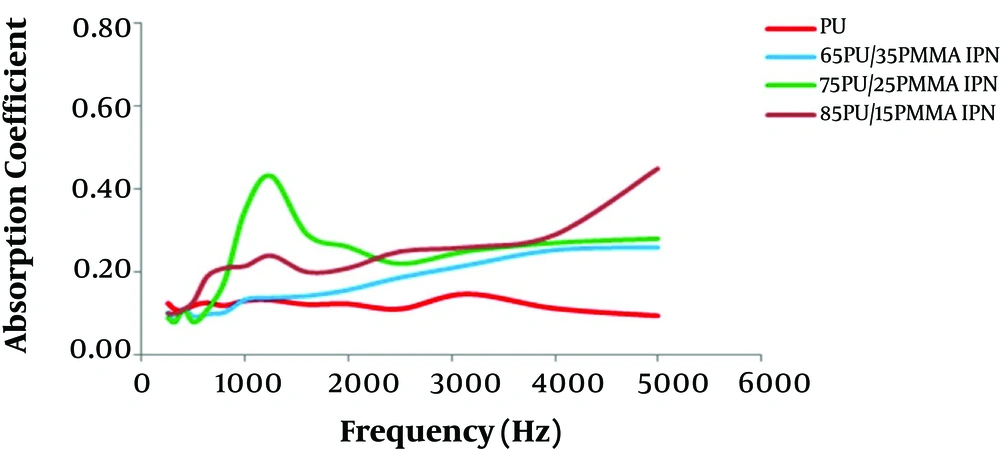

In this section, the PU/PMMA acoustic absorption behavior of IPN was evaluated by changing the content of PMMA through the samples. In Figure 4, the absorption coefficient of the PU and PU/PMMA IPN samples with different PMMA contents is shown with the same thickness (1.5 cm) with a narrow band. Using the absorption measurement data, the average absorption coefficient for samples was calculated and the results were plotted in Figure 4. As can be seen, a specific trend for sound absorption can be observed in any composition range. The maximum amount of sound absorption coefficient was obtained at 1250 Hz as 0.44 for the 75PU/25PMMA IPN.

4.4. SEM

In Figure 5, SEM micrographs of the cross-sectional fracture of the samples are shown. With increasing PMMA, the number of cavities associated with the reduced polymer and a good dispersion of the dispersed phase in the field are observed. SEM results show the two-phase morphology in the IPN system and reveal the uniform distribution of the second phase (PMMA) in the first phase (PU).

5. Discussion

A gradual increase in the undesirable and hazardous noise level has perplexed our living and working environment; therefore, noise reduction is a very important issue (22). One of the methods to control sound and vibration involves the use of materials with a high damping capacity at a certain temperature and in a frequency range. In most cases, these materials should have a high mechanical resistance and good thermal stability (23).

As seen in our research, FTIR test showed the formation of the characteristic NH bond in the wave number between 3100 and 3300 cm-1, the removal of the characteristic poly-tetrahydrofuran -OH band (PTMG) at 3480 cm-1, and no characteristic absorption band of N=C=O at 2235 cm-1, confirming the full PU reaction and interpenetration of PMMA with PU prepolymer (11). The disappearance of these bands approves the completion of curing reactions by the polymerization of PU and PMMA components and hence, the formation of the desired IPN grades. The results of this study are consistent with those obtained by Moradi et al. (15).

The ability of elastomers to absorb acoustic and mechanical energy is demonstrated by their dynamic viscoelastic properties. The semi-compatible morphology of elastomers and broader glass transmission temperature ranges are the desirable features in the application of sound absorbing materials.

The storage modulus (E’) predicts the phase continuity and phase inversion of a polymer composition at a certain temperature (24). The distinct and narrow peak of loss factor (tan δ) indicates a high inter-compatibility between two phases. Two distinct peaks with the lower tan δ (inter-transition) show a large phase separation (24, 25). In addition, two separated peaks with the same altitude for tan δ may indicate a phase continuity or a phase inversion (24, 25).

Dynamic mechanical analysis is a useful assay for determining the loss and elastic modulus of polymers and IPNs as a function of temperature, frequency, or time (26). Generally, materials that have a large and high loss factor can be used as a dampening agent. tan δ is the ratio of energy dissipation in the heat to the maximum stored energy in the sample, which is defined as the loss modulus (E’’) on the storage module (E’), (i.e., tan δ = E’’/E’) (26). Often, the polymeric materials that have a tan δ of higher than 0.3 in a given temperature range are used as standard materials for evaluating damping capacity (19).

Figure 3A shows that the 65/35 IPN had a higher storage modulus than the other prepared IPNs. This higher storage modulus can be attributed to an increase in the PMMA component in this synthetic IPN. It can be concluded that increasing PMMA content in the IPN results in an increase in the polymeric strength (7). This may be a reason for increasing the storage modulus of 65/35 IPN relative to the other two synthetic IPNs (i.e., 75/25 and 85/15 IPNs). Studied indicate that the increase of modulus is related to the interaction and/or interpenetration of the phases.

Figure 3B shows the formation of IPN with PU and PMMA causes the maximum tan δ to be shifted to the room temperature. This effect is due to the permeability of the two polymers because of a semi-incompatible morphology. The internal movement and transmission width for PU and PMMA polymer components and the creation of a semi-membrane structure represent the formation of an IPN system.

According to Figure 3B, the reason for the decrease in tan δ is a consistent glass polymer, i.e. PMMA, which prevents semi-crosslinking from moving to the part of the chain by causing a decrease in the tan δ peak value. The Tg change to higher temperatures indicates the permeability of the phases in the IPN system. The results are consistent with those of Kong and colleagues (27).

In this study, damping in IPNs and its basic components was studied. The comparison of the PU and PMMA curves with the synthetic IPNs showed a semi-compatible morphology through the extension of tan δ and the presence of two distinct transition peaks. In addition, it can be seen the presence of PMMA as a hard phase caused a shift in Tg at higher temperatures. This status is favorable for a successful sound and vibration absorber (27). The results of this study are consistent with those obtained by Klempner et al. (20).

Whereas the pure PU tends to peak sharply at a narrow temperature range, all IPNs, especially at a composition of 75/25, showed somewhat high damping within the temperature range. It can be concluded that by forming the IPN composite, the glass transition temperature (the peak curve of the loss factor as Tg) is shifted to higher temperatures and the temperature range of the damping (temperature range with > 0.3 tan δ) is broader, thus the PU/PMMA IPN improves the damping properties. In addition, with an increase in PMMA, the attenuation (temperature range with > 0.3 tan δ) increased in a specific temperature range in the PU/PMMA IPNs composites. tan δ graph as a function of temperature for polyurethane-methyl methacrylate IPN showed that among different mass ratios of IPNs, the 75/25 IPN shows increased damping as the extensive tan δ content in the temperature range of -24 to 11°C, which can be a good sign of attenuation for sound and vibration adsorption applications. This may be due to the continuous phase morphology and a better permeability for this mass ratio of PU/PMMA IPN.

In accordance with the concept of acoustic reduction, the absorption coefficient refers to the fraction of the sound wave that may be observed when the sound wave hits the specimen and varies from 0 (no reduction) to 1 (100% reduction). The absorption coefficient of PU is relatively less than that of synthetic IPNs, and as stated in the previous sections, the sample damping properties are better in an IPN state than in pure PU specimens. As shown in Figure 4, the 75/25 IPN showed a significant increase in the absorption coefficient compared to the other two IPNs. This is in accordance with the results obtained from the DMA test. It is likely that by increasing the PMMA ratio, the resonance frequency will be pulled to the lower frequencies. It seems to be due to the friction between the rubbery and glass phases depending on the morphology.

As shown in Figure 5, the PU/PMMA structure of the IPN is completely different from the structure of PMMA and the PMMA permeability is clearly shown in the PU network.

5.1. Conclusion

In the present study, the IPN networks of PU and PMMA were prepared by using the sequential polymerization process with different ratios of PU/PMMA (85/15, 75/25, and 65/35). SEM results showed the two-phase morphology in the IPN system and revealed the uniform distribution of the second phase (PMMA) to the first phase (PU). The comparison of the curves of synthetic IPNs with PU and PMMA curves showed a semi-compatible morphology through the extension of tan δ and the presence of two distinct transition peaks. The results of the absorption coefficient indicated that due to the formation of IPN, the performance of the substance at a certain frequency would be reactive or exacerbated. It is likely that by increasing the PMMA ratio, the resonance frequency will shift to the lower frequencies. With the formation of IPN composites, effective damping is expanded which improves the sound absorption properties. By varying the composition of IPN and adjusting the molar ratio of PU to PMMA in the IPN composite, it is possible to design a sound-damping material by considering other engineering properties such as damping and tensile strength.