1. Background

Today, noise exposure is one of the most important problems in workplaces and general environments. Exposure to noise for long time and/or with high level in any situation can cause adverse effects on health, including auditory and non-auditory. In auditory adverse impacts, the hearing system gets directly involved and finally the hair cells get damaged by noise, which is called noise-induced hearing loss. The non-auditory effects include many different fluctuations in physiological conditions such as increase in heart rate, blood pressure, adrenaline and cortisol hormones excretion, etc. (1-3). Therefore, noise is a risk factor that exists in any type of industries (small, mid and large scale) (4). Oil industry is one of the mega industries that has a very important role in industrial development, specifically in countries with gas and oil natural resources. The main step in oil extraction is to prepare a drilling floor and by drilling and cutting the earth, access to an oil field will be achieved; this procedure is called drilling.

Many workers are involved in a vast verity of different positions in this industry and are often exposed to noise. Many studies have shown that noise exposure in oil industries are above the occupational exposure limit of 85 dB (A) (5, 6). Golmohammadi et al. showed that time-weighted average and max noise level in an oil refinery was above the determined limits (7). Chen and Tsai studied hearing loss in 384 workers at an oil refinery in Taiwan. Their results showed an increased hearing threshold shift for high frequencies, in workers who had chronic noise exposure for more than 15 years (8). Nassiri et al. evaluated environmental noise exposure in a petrochemical complex; their results explained that sound pressure levels in 88% of the points of the whole study area were above the occupational exposure limit (9). Kumar et al. showed that workers in oil mills had noise exposure and this exposure effected their health (10). Monazzam et al. explained an environmental noise level in a petrochemical complex above the determination limits (11). Cioca et al. showed that the noise sources varied in oil drilling and production platforms and high noise levels in these work places occurred regularly (12).

2. Objectives

The aim of this study was to determine the noise exposure levels in oil drilling rig floor and camp facilities in Ahvaz.

3. Materials and Methods

This was a cross-sectional study; at first, data regarding rig floor geographical location, operations and camp layout were gathered. Environmental and personal noise exposure measurements were carried out by the method established by ISO-9612 (13) with a sound level meter (Cel-328 model made in UK) in a sunny day (temperature 30°C, RH 54%, air pressure 214 mmHg and mild air velocity). By the gridding method, the area was divided to squares (10 × 10 m) and sound pressure levels were measured at the center of each square. In outdoor measuring, the microphone of the sound level meter was placed 1.5 meter above the floor and 3.5 meters away from any reflecting surface. The noise emission pattern in the rig floor was of a fluctuating nature and there were several noise sources in the area. Therefore, for determining the workers’ real noise exposure, the equivalent of sound level (Leq) was used as bellow: (14). The equivalent of sound level

Where, ti: fraction of time in interval i (hour), lpi: a weighted sound level of interval (dBA).

Also, by the help of a noise level dosimeter (Cel-320 model, UK), noise level dose measurement in the operation and camp environment were carried out.

4. Results

All the measurements were performed in two parts of an oil drilling rig, operation and camp areas, with a total of 120 male workers, working in the two parts (96 in the operation area and 24 in the camp area). Job rotation in the operation area workers included three eight-hour shifts.

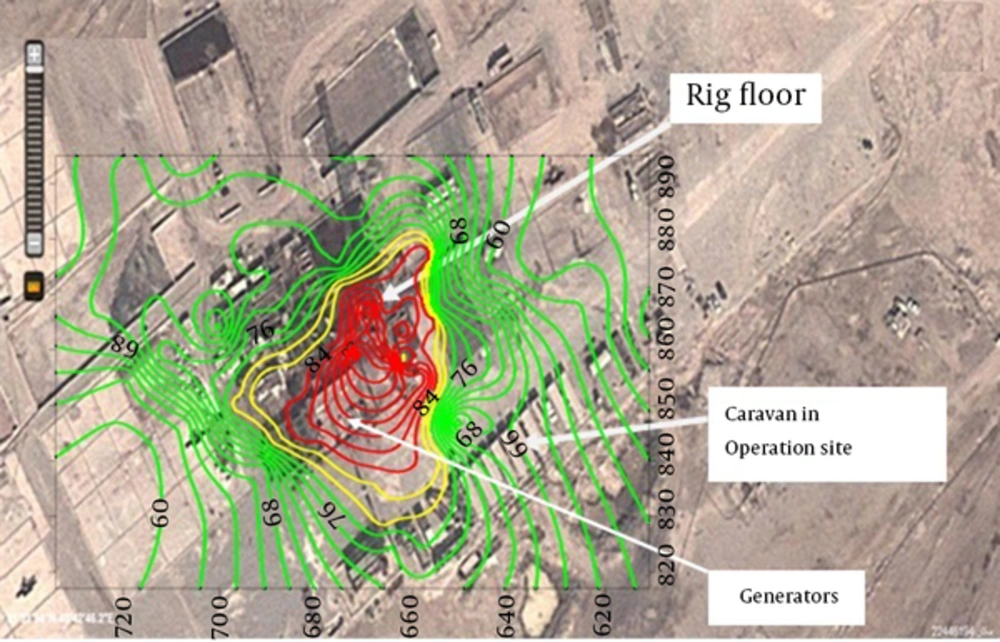

The noise levels in 100 points in the rig area were between 54 - 110 dB. Figure 1 shows the noise emission pattern in the oil drilling rig area. Table 1 presents the results from the noise levels in the operation zone. The noise levels inside the caravans which were located in the operation area of the rig floor were between 55 - 78 dB (A). The noise levels were measured in 38 points in the camp area as well and ranged from 52 - 100 dB. Table 2 shows the noise levels measured in every job category in operation and its camp areas.

| Work Station/Source | Sound Pressure Level, dB-A | Sound Pressure Level, dB | Number of Exposed Workers | Occupancy Time in a Sift Duration, h |

|---|---|---|---|---|

| Engine generators | 105 | 110 | 6 | 1 |

| Mud pumps | 87 | 94 | 12 | 5 |

| Draw works | 91 | 100 | 7 | 8 |

| Rotary table | 89 | 103 | 7 | 8 |

| Water pumps | 93 | 98 | 4 | 1 |

| Mud return | 95 | 99 | 4 | 1 |

| Desander and Desilter | 100 | 101 | 2 | 1 |

| Sieves shaker | 92 | 102 | 2 | 3 |

| Compressors | 95 | 99 | 4 | 1 |

| Mud shaker | 87 | 91 | 3 | 4 |

| Mud pits pump | 87 | 95 | 1 | 5 |

| Kelly bashing | 105 | 109 | 4 | 3 |

| Elevator | 85 | 88 | 7 | 4 |

| SCR | 81 | 90 | 4 | 8 |

| Draw works water pump | 95 | 97 | 7 | 4 |

| Camp generator | 100 | 103 | 2 | 1 |

| Rest caravan in rig site | 71 | 74 | 10 | 4 |

| Management caravan in rig site | 76 | 78 | 16 | 7 |

| Rest caravan in camp | 69 | 71 | - | - |

a Abbreviation: SCR, Switch control room.

| Job | Number | Dose, % | Leq-8 h, dB-A |

|---|---|---|---|

| Tool pusher a | 2 | 87 | 78.4 |

| Night tool pusher a | 2 | 85 | 78.4 |

| Driller a | 4 | 111 | 88.5 |

| Assistant driller a | 4 | 89 | 81.2 |

| Head mechanic man a | 2 | 91 | 83.2 |

| Head electrician a | 2 | 85 | 79.8 |

| Mud Engineer a | 2 | 84 | 78.7 |

| Mechanic a | 2 | 93 | 85.4 |

| Electrician a | 2 | 88 | 83 |

| Rough neck | 2 | 85 | 79 |

| Welder a | 2 | 85 | 80.8 |

| Crain driver a | 2 | 80 | 77.7 |

| Rig physician a | 2 | 65 | 76 |

| Deriver a | 2 | 70 | 77 |

| Ambulance Driver a | 2 | 80 | 81.8 |

| Floor Personnel a | 12 | 110 | 90.2 |

| Well site geologist a | 2 | 75 | 75.5 |

| Derrick man a | 4 | 95 | 86.8 |

| Company man a | 4 | 75 | 78.4 |

| Mud worker a | 12 | 90 | 84.4 |

| Engineer a | 2 | 105 | 88 |

| Engineer in camp b | 2 | 80 | 81.1 |

| Truck deriver a | 2 | 75 | 79 |

| Wash cool a | 4 | 95 | 84.5 |

| Camp officer b | 2 | 65 | 78 |

| Head chefb | 2 | 55 | 75.7 |

| Cook | 2 | 55 | 75.7 |

| Chef assistant b | 2 | 55 | 75.7 |

| Room man | 6 | 95 | 79 |

| Warehouse man b | 2 | 55 | 76.7 |

| Baker | 2 | 75 | 80 |

| Lodger b | 4 | 75 | 78.9 |

| Dish washer b | 2 | 55 | 77 |

| Radio man b | 4 | 80 | 79.7 |

a Operation area worker.

b Camp area worker.

5. Discussion

This study was a unique one regarding environmental noise level measurement in rig floor in Ahvaz, Iran. Our results showed that only 17% of the measured points in oil drilling rig floor were in safe area (< 65 dB (A), green); 39% of the points were in caution area (65 - 85 dB (A), yellow) and 44% were in danger area (> 85 dB (A), red). In the camp facilities area, 51% of the points were in safe area, 38% were in caution area and 11% in danger area. The main sources of noise exposure in the rig floor area were power generators, due to the position of which in the drilling site, all the workers were exposed to their noise. Three of these generators with 2000 and 2500 horse power (two with eight pistons and one with 12 pistons) were used to generate the needed power for the total drilling operation, the produced sound pressure levels of which were equal to 110 dB. Since their installation and location in the area had engineering and technical limitation, the generators should be installed near the rig floor, and thus, they generally become the main noise sources that cause hazardous noise exposure for all workers; the more activity in rig floor or near to it, the more exposure to noise. In combination with other noise sources in the rig floor site, the emission of sound pressure level was above 85 dB. Attention should be paid to this fact that it was only the power generators that were always continuously working and other sources were alternatively on. The results from dosimeter at all job stations in the operation site explained that workers had exposure to above the safe limit of exposure, especially in 3 job positions (four drillers, 111%; 12 rig floor workers, 110%; two power men, 105%). In other jobs, the recorded noise dose was lower than the safe occupational limit, but the equivalent sound levels in eight hours were above the allowable limit of 85 dB (A). Our results are supported by Cioca et al. (12). The results from this study revealed that the instant average sound pressure in most of the points in drilling rig floor were over the proposed safe noise limit and in 18.75% of the positions, workers received noise levels above the allowable limit. This result is the same as other studies that investigated other parts of the oil industry (5-9, 12).

As a conclusion, exposure to noise in drilling rig floor like every other parts of the oil industry is significant and considering that a drilling rig is installed for a short period of time in an area and by the time it reaches the intended natural resource, drilling operation ends up and the whole site would be carried away to another place for a new project. Therefore, applicable methods for reducing noise exposure with such pre-assumptions need to be more flexible. This finding was supported by Gardner (6). With regards to this fact that the main sources of noise are power generators which should be installed near the rig floor, increasing the distance principle is of no use. Due to the wide usage of rig floors, before installation and initiation of a drilling area project, the mentioned power generators should be positioned so that the exhaust direction locates at the opposite side of caravans and the indoor rig site. Furthermore, by using flexible partitions/semi walls around power generators, they can be separated from other active parts on the rig.