1. Background

The lack of predictability of the nature of projects makes them riskier day by day. By considering possible alternatives, the risk in the project can be reduced, and a reference project can be provided to the decision-makers to reduce the relevant costs (1). Today, organizations strive to create environment, health, and safety (EHS) management, a proper system to maintain and improve a healthy work environment without any accidents, injuries, and pollution. The EHS management system is a tool to control and improve the performance of health, safety, and environment in all industrial and nonindustrial development programs. Actually, it is an integrated system that all sources, including humans, equipment, and financial, are used to support each other to ensure the workplace free from any accident and injurie (2).

In today’s highly competitive world, numerous companies have realized that they need to make EHS management an integral and essential part of their system and value it as much as they value other management systems in the organization. The ultimate goal in EHS management is to protect individuals, property, and the environment (3). This management system takes steps toward sustainable development, reduction of costs, and increase in productivity by preventing injuries, by EHS events, and by considering the health and safety of employees and other individuals affected by the current activities of the organization (4). Recent psychological studies examining accidents and their causes refer to age factors, experience level, and personal characteristics of employees from a management point of view (5).

On the other hand, Hayes believes that 88% of unsafe behaviors, 10% of unsafe conditions, and 2% of unforeseen factors play a role in accidents. Since the second half of the 20th century in developed countries, with the emergence of the role of insecure acts of individuals, the basis of accident control has focused on unsafe behaviors of individuals (6). Studies on unsafe behaviors have shown that occupational stressors play a significant role in the occurrence of unsafe actions by employees through reduced concentration, distraction, memory impairment, hesitation in doing things, and reduced decision-making power (7).

Today, the maritime transport industry is of great importance in the economic cycle of countries. More than 90% of the world’s exports and imports are made by sea (8). Because port terminals face numerous risk factors due to some issues, such as day-to-day activities, environmental conditions, technology development, and increasing fields, each of these risk factors produces different results (9). Port activities are mainly carried out in two main areas, including the area next to the pier and the area inside the terminal. Offshore activities include mooring ships, loading and unloading them using dock cranes, and moving goods by port vehicles to warehouses. The area of activity inside the terminal is diverse, the most important of which include unloading and loading trucks carrying goods and storing export and import goods in separate areas inside the terminal. Each of these activities has hidden and obvious risks and dangers, which can include the fall of goods during unloading and loading and equipment failure (10).

Various researchers have paid attention to the safety of port operations; however, their main focus has been on the safety of unloading and loading certain goods. Shang and Lu (11) and Jafari et al. (12) studied only the safety dimension in container operations. Nevertheless, at present, most internal studies examine the performance of the EHS unit in ports, including studies by Amir-Heidari et al. (13) and Alimohammadlou et al. (14). Due to the increase of port activities, the establishment of numerous contracting companies in the port environment, and the variety of jobs and port equipment, the active labor force has faced many dangers.

2. Objectives

This study attempted to identify and prioritize the risks of each of these activities in unloading and loading operations in Chabahar port, Chabahar, Iran.

3. Methods

This was an applied qualitative study to prioritize the EHS risks of unloading and loading operations in Chabahar port using Shannon’s entropy technique in 2020. The steps of this study are designed as follows:

3.1. Statistical Population

The statistical population of this study included all managers, EHS experts, port and maritime affairs experts of unloading and loading companies, and transportation companies of Chabahar port. This population included 90 individuals, from whom a statistical sample of 83 individuals was selected (12).

3.2. Identifying the Risks of Loading and Unloading Operations

The existing risks of unloading and loading goods in ports were identified using valid national and international studies (12, 15).

3.3. Identifying the Risks of Loading and Unloading Operations at Chabahar Port

The risks that occurred during the last 5 years (2014 - 2019) in Chabahar port and during the unloading and loading of goods were taken from the EHS unit of this port (12, 15).

3.4. Interviewing Experts and Finalizing the List of Risks

Port and marine experts working in Chabahar port for more than 10 years were interviewed using a semi-structured interview. In the structural part, the identified risks in library studies were presented to them, and the compliance or noncompliance of those risks with the conditions of unloading and loading operations in the field was requested. Finally, they were asked to indicate further risks (16).

3.5. Shannon’s Entropy Technique

The risks were prioritized through Shannon’s entropy decision technique. Identified risk factors were prepared in the form of a questionnaire and distributed among the experts.

3.5.1. Validity and Reliability of the Questionnaire

In order to ensure the accuracy of the questionnaire, the authors validated the above-mentioned questionnaire with the help of 10 experts in the relevant field. The Waltz and Bausell method was used to evaluate the content validity index (CVI). The experts identified each item as relevant, clear, and simple based on a four-point Likert scale. The experts rated each item as (1) not relevant, (2) relatively relevant, (3) relevant, and (4) completely relevant. The simplicity of the item was from (1) not simple, (2) relatively simple, (3) simple, to (4) quite simple, respectively. The clarity of the item was from (1) not clear, (2) relatively clear, (3) clear, to (4) quite clear. The minimum acceptable value for the index was 0.79, and if the CVI of an item was less than this value, that item should be removed. Equation 1 represents the CVI (17-19).

The reliability of the questionnaire is shown in Table 1 and was confirmed according to the result of Cronbach’s alpha test in SPSS software (version 22) (20).

| Group | Items Number | Cronbach’s Alpha |

|---|---|---|

| Safety | 1 - 10 | 0.894 |

| Health | 11 - 19 | 0.735 |

| Environment | 20 - 26 | 0.743 |

| Total | 1 - 26 | 0.803 |

Cronbach’s Alpha Test

3.5.2. Prioritizing Risks

Shannon’s entropy decision-making technique was used to prioritize the identified risks. The steps of this method are as follows:

Step 1: First, the decision matrix is formed. To form this matrix, it is enough to decide if the criteria are qualitative to evaluate each option in relation to each criterion from the verbal expressions and if the criteria are quantitative to put the actual number of that evaluation. In Equation 2, which is the decision matrix, the columns are the criteria and rows of options. For example, in x12, the score is the first option, compared to the second criterion (21, 22).

Step 2: Normalize the above-mentioned matrix and call each normalized item pij. Normalization is achieved by dividing the value of each column by the sum of the columns (21, 22).

Step 3: Calculate the entropy of each index: The entropy of Ej is calculated as Equation 3, and k holds the value of Ej within 0 and 1 as a constant value (21, 22).

Where p (x) is the probability distribution of the random variable X. An increase in Shannon’s entropy increases uncertainty and decreases the knowledge of the random variable. Another interesting aspect of Shannon’s entropy is its maximum entropy property for uniform distribution.

Step 4: Next, the value of dj (degree of deviation) is calculated, which expresses the relevant index (dj) and how much helpful information for decision-making is provided to the decision-maker. The closer the measured values of the index are to each other, the more likely the competing options are to differ from each other in terms of that index (Dj = 1 - Ej). Therefore, the role of that index in decision-making should be reduced equally (21, 22).

Step 5: Then, the weight value of Wj is calculated. The standard weight is equal to each dj divided by the set of djs.

3.6. Ethical Considerations

All information about the EHS team, port experts, and other issues will remain confidential. Each participant could be excluded from the study at any research stage.

3.7. Data Analysis

After collecting the questionnaires provided to the experts in the field of safety, along with the matrix of pairwise comparisons and determining the degree of priority, the relevant information was extracted, and the first information processing was performed by expert choice and Excel software. After ensuring the acceptability of the obtained priorities, the average of the comments presented was calculated by the geometric mean method and the coefficients of each of the comparisons’ matrices. Since the different opinions of individuals had to be merged into a questionnaire before entering the software, the geometric mean formula was used for this purpose, which is presented in Equation 4 (23, 24).

4. Results

4.1. Identified Risks

Based on library studies and interviews with experts, a total of 26 EHS risks were identified, as shown in Table 2. In the safety group, machine failures, individuals falling into the sea, and ships colliding with the dock were examples of risks. Examples of health risks were noise, vapors and fumes, and the lighting of the operating area.

| Group and No. | Risks |

|---|---|

| Safety | |

| 1 | Crane falls |

| 2 | Container falls from unloading and loading equipment |

| 3 | Errors in container handling and refining operations |

| 4 | Damage to equipment |

| 5 | Machine failure |

| 6 | Explosion and fire equipment |

| 7 | Individuals falling into the sea |

| 8 | Ships colliding with the dock |

| 9 | Vehicles colliding with each other and dock equipment |

| 10 | Pier subsidence |

| Health | |

| 11 | Related to dangerous goods |

| 12 | Dust related to goods |

| 13 | Existence of first aid |

| 14 | Job fatigue |

| 15 | Vapors and fumes |

| 16 | Noise and vibration |

| 17 | Working in abnormal air temperatures |

| 18 | Ergonomic items |

| 19 | Operating area lighting |

| Environment | |

| 20 | Land and aquatic habitat change and biodiversity |

| 21 | Weather changes |

| 22 | Water quality |

| 23 | Waste management |

| 24 | Air pollution |

| 25 | Management of hazardous materials and oil |

| 26 | Invasion species |

Environment, Health, and Safety Risks of Unloading and Loading Operations of Chabahar Port, Chabahar, Iran

4.2. Prioritization of Risks

This section describes how to calculate environmental risks, and the final prioritization table will be provided only for safety and health risks. These risks are abbreviated as follows to enter the analysis tables:

- Waste management (a1)

- Management of hazardous and petroleum products (a2)

- Water quality (a3)

- Land and aquatic habitat change and biodiversity (a4)

- Air pollution (a5)

- Climate change (a6)

- Invasive species (a7)

In this study, the risks were compared in terms of probability of occurrence (O), probability of discovery (D), severity (S), and financial effects (F).

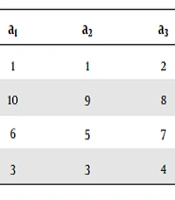

Table 3 shows the decision matrix of the environmental risk group. This table is based on the average responses of 83 questionnaires.

| a1 | a2 | a3 | a4 | a5 | a6 | a7 | |

|---|---|---|---|---|---|---|---|

| Occurrence | 1 | 1 | 2 | 4 | 2 | 4 | 1 |

| Discovery | 10 | 9 | 8 | 5 | 9 | 5 | 9 |

| Severity | 6 | 5 | 7 | 8 | 7 | 9 | 5 |

| Financial | 3 | 3 | 4 | 5 | 4 | 5 | 4 |

Decision Matrix of Environmental Risk Group

The probability of occurrence of each option was then calculated, as shown in Table 4. How to calculate a1 probability of occurrence is as follows:

P11 = 1/20 = 0.05

| a1 | a2 | a3 | a4 | a5 | a6 | a7 | |

|---|---|---|---|---|---|---|---|

| Occurrence | 0.05 | 0.055 | 0.095 | 0.181 | 0.09 | 0.173 | 0.052 |

| Discovery | 0.5 | 0.5 | 0.38 | 0.277 | 0.409 | 0.217 | 0.473 |

| Severity | 0.3 | 0.277 | 0.33 | 0.363 | 0.318 | 0.391 | 0.263 |

| Financial | 0.15 | 0.166 | 0.19 | 0.227 | 0.181 | 0.217 | 0.21 |

Probability of Occurrence of Environmental Risk Indicators

In the next step, the entropy value of each criterion is obtained (Table 5). Before obtaining E, it is necessary to obtain the value of K, which was calculated as follows:

Additionally, Table 5 shows the value of the degree of deviation (d); for slot O, it was calculated as follows:

d = 1 - 0.821 = 0.179

| a1 | a2 | a3 | a4 | a5 | a6 | a7 | |

|---|---|---|---|---|---|---|---|

| Entropy | 0.821 | 0.834 | 0.915 | 0.972 | 0.904 | 0.96 | 0.853 |

| Degree of deviation | 0.179 | 0.166 | 0.085 | 0.028 | 0.096 | 0.04 | 0.147 |

Entropy (E) and Degree of Deviation (d) Values of Environmental Risks

Table 6 shows the weight of each indicator (W) of environmental risks, health risks, and safety risks. For slot O, it was calculated as follows:

| a1 | a2 | a3 | a4 | a5 | a6 | a7 | a8 | a9 | a10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Weight of each indicator | 0.241 | 0.224 | 0.114 | 0.037 | 0.129 | 0.054 | 0.198 | - | - | - |

| 0.044 | 0.126 | 0.211 | 0.122 | 0.094 | 0.061 | 0.148 | 0.031 | 0.161 | - | |

| 0.149 | 0.025 | 0.018 | 0.02 | 0.191 | 0.206 | 0.106 | 0.028 | 0.1 | 0.153 |

Weight (w) of Environmental Risks, Health Risks, and Safety Risks

5. Discussion

This study was carried out to identify and prioritize the EHS risks of the unloading and loading operations of goods in the Chabahar port using Shannon’s entropy technique. The results showed that in the safety group, the risk of explosion and fire was identified as the most important risk. Machine failure and pier subsidence were the next priorities. Afterward, the least significant risk was related to the damage to pier equipment. In the health group, working in abnormal air temperatures was the most important risk. After that, operating area lighting and dangerous goods were the next priorities, and ergonomic cases were identified as the least significant risk. Moreover, the results of the environmental risks showed that waste management was identified as the most important risk. Hazardous materials and oil and invasive species were the next priorities, and then terrestrial and aquatic habitats and biodiversity were regarded as the least significant risks. This study identified the risk of explosion and equipment fire as the most important issue in port safety.

Kiani Moghadam and Sohrabi (25) addressed the risk of fire and explosion in oil tankers, and their findings showed that fire in deck equipment causes the fire to spread to the entire ship and destroy it. The aforementioned results are consistent with the results of the present study. In another study conducted by Moin Kia on the Sanchi ship fire, it was found that the collision of a Chinese bulk car with the hull caused the explosion of equipment in the ship’s warehouse and the transfer to crude oil and light oil condensate, destroying the entire ship and killing all its crews. The Beirut port warehouse accident also caused $15 million in damage to the city. All these investigations and real incidents showed the importance of considering the risk of explosion and equipment fires in ports, which cause many human and financial losses, and are relatively consistent with the present study.

The present study identified the risk of operating at abnormal temperatures as the most important risk to the port health sector. In 2017, the international labor organization issued guidelines on safety and health in ports. One of the health effects on workers’ performance is air temperature. High temperatures cause workers to overheat and lose their focus and balance during work. Nassiri et al. (26) found that heat, as one of the most harmful physical factors in numerous work environments, can create thermal stress, increase the risk of injuries and accidents, and decrease efficiency and effectiveness. Furthermore, it is considered a major occupational health problem that is consistent with the results of the present study.

This study identified the risk of waste management as the most important issue in the port environment. Hedayati and Bagheri (27) stated that ship wastes refer to any type of harmful substance (both for the marine environment and public health) that is produced during the normal daily operations of ships. Their findings showed that 45% of ship pollution is related to ship wastes and oil wastes, which, if these wastes enter the port waters, will cause irreparable environmental pollution in the port, which is consistent with the results of the current study. According to a study by Rezazadeh and Dana (28), dangerous goods in ports always have a great potential for accidents and severe damage to manpower, environment, and equipment. Given the diversity and breadth of activities and the relatively high level of vulnerability in ports, it is essential to fully observe and continuously monitor EHS considerations and criteria in operations related to dangerous goods. Therefore, in this study, in order to provide a comprehensive and reasonable assessment of the criticality of the container terminal of dangerous goods in ports in terms of the risk of accidents caused by working with dangerous goods, six crucial EHS indicators were extracted from the standards of the World Maritime Organization. Then, the determined indicators were weighed on a case-by-case basis in Bushehr port using a hierarchical analysis method and based on the opinions of port affairs experts. The findings showed that the emergency preparedness index, with a value of 0.301, and the special activity control index, with a value of 0.039, had the highest and lowest weight and importance among the six indices, respectively.

Fazlollah et al. presented a method for the assessment of EHS risks using multicriteria decision-making methods (case study: Power plant construction) (29). The results showed that the usual method of risk assessment could not prioritize risks accurately. Although the 10 main risks identified in the existing method were in 4 general categories, the proposed method could prioritize them into 7 categories. This makes it possible to allocate more organizational resources to control risks. Taheri and Yahya Tabar studied the performance of EHS management in the Caspian Sea ports (30). Then, the hypotheses of the seven variables of EHS management, including leadership and commitment, policy and strategic goals, organization, resources, and documentation, risk assessment and management, audit and review, implementation, and monitoring and planning, were discussed. The results showed that the situation of seven variables of EHS management in the Caspian Sea ports was favorable. Moreover, according to the Friedman test, the variables of leadership and commitment (the first variable) were the most important of all variables. Delavaran Shiraz and Kosarizadeh (31) expressed that due to the high potential of Imam Khomeini port in Iran for the construction and development of unloading docks, loading export and import goods, construction of warehouses for goods, construction of access roads, and expansion of communication routes, and development of Imam Khomeini Port Sewerage Network can have potential effects and consequences on the environment of the region, including physical, chemical, ecological-biological, economic, social, and cultural environments.

According to the research findings, the strategy of providing EHS management system infrastructure financially and using appropriate technology and specialized manpower was selected as the best strategy. Mapar et al. (32) examined sustainable indicators of health performance integration, safety, and the environment of municipalities in large cities. A total of 80 indicators were compiled and divided into 13 groups. The results showed that among the total scores of 13 groups, “fire response and emergency response” was the most important part, followed by the categories “waste”, “transportation”, and “natural systems”, respectively. In addition, among the seven proposed topics, the integrated “EHS” theme, which is almost followed by the “safety” theme, plays an essential role in improving EHS performance in sustainability in municipalities.

It is recommended to separate individuals from traffic areas and to provide one-way traffic routes for vehicles. Moreover, several issues, including designing the movement of goods management operations, the possibility of achieving a simple and linear plan, and reducing the need for several points of movement that can reduce the likelihood of accidents and injuries, safe access appropriate to the size and type of vessels using port facilities, such as guard rails, and providing appropriate safety nets between ships and adjacent piers, should be considered. Entry plans should include methods that prevent the use of combustion equipment, including refueling activities inside cargo tanks and in spaces where there is no alternative to the exit, slowing or minimizing them to reduce the risk of explosion and equipment fire. At the time of arrival of ships at the port, stop time should be considered for the equipment; accordingly, the device does not ignite due to excessive use and high temperature and sultry air in Chabahar. On the other hand, a fire extinguisher should be installed in the equipment; accordingly, in case of ignition, the operator can turn it off initially so that the port fire brigade can reach the accident site. For the reduction of the risk of machinery failure, periodic inspections of the equipment are required to identify devices, reduce the risk of pier subsidence, use soil-oriented civil engineers to measure ground strength, and calculate factor loads associated with equipment and goods at each pier.

The following suggestions can be considered to reduce health risks; for the reduction of the risk of working in abnormal weather temperatures, it is recommended that the EHS office determine the allowable amount of work when the weather is hot, and it should be mentioned to the unloading and loading companies and port and maritime affairs of the port office to reduce the risk of fire in the operational area. It is necessary for the port power unit to continuously inspect the lighting equipment of warehouses and docks and replace the new equipment with defective and worn-out ones. For the reduction of the risk associated with dangerous goods, it is necessary to fully explain the specifications of the goods to be unloaded, along with the consequences for unloading and loading operations by the shipping line representative or the EHS port authorities.

For the reduction of the risk of waste management, the port EHS unit should prepare a form in which all the wastes that a ship might have should be listed and answered by the ship’s captain. Therefore, based on that, the wastes are sorted and removed from the port. For the reduction of the risk of hazardous materials and oil management in Chabahar port, the officials of the port pollution control unit must fully comply with international guidelines to prevent the spread of pollution in this port. To reduce the risk of invasive species, the ship’s balance water must be collected, and the port must provide its own balance water to the ship to align with.

5.1. Conclusions

Based on the results of the study, in each of the EHS groups, the risks of explosion and fire of equipment, working in abnormal air temperatures, and waste management were identified as the most important risks, respectively. In addition, the unloading and loading of goods in Chabahar port faced more safety risks, and further focus should be placed on the safety dimension than the other two dimensions because, in the event of safety risks, there is a possibility of losing manpower and increasing side costs.