Dear Editor,

The nature of the effluents produced in an environment could be understood by sampling and examining materials and particulates in wastewater, and various methods are chosen and implemented for treating and eliminating pollutants (1). The validity of the analyzed data depends greatly on the precision of the sampling procedure (1, 2). Conventional and traditional wastewater sampling is often performed manually using a container attached to a rod or stick (2). Such sampling has major drawbacks, including:

(1) Impossibility of collecting wastewater from the desired depth because treatment plant designers, operators, and researchers in wastewater treatment plants always study various biological, chemical, and physical parameters and evaluate the effectiveness of a process at a certain depth to perform specialized tests and assess the efficiency of a specific part of the treatment plant (3). Therefore, collecting wastewaters from the desired depth requires particular attention because in the usual sampling methods (2), after immersing the container connected to a rod into the wastewater stream, given that the container lid is entirely open, at the first moment, the container is filled with wastewater. Increasing the depth of sampler immersion does not alter the volume and composition of the collected specimen, and almost the entire volume of the sample container is allocated to the initial depths of wastewater.

(2) The health of sampling operators and researchers is under threat due to the highly pathogenic nature of wastewater and the depth of wastewater ponds (4). Atashkar et al. emphasized that sampling and contact with wastewater, particularly during outbreaks such as COVID-19, is very hazardous for workers in wastewater treatment plants (4). The sampler worker must have a certain distance from the wastewater ponds to minimize the risk of falls and contact with disease agents. This problem is still unresolved and a concern because of the conventional sampling currently being used.

(3) Another problem that needs to be considered is the lack of a suitable depth index (altimeter) to detect the sampling depth. Therefore, the depth is currently guessed in the in-depth wastewater sampling.

Complex sewer sampling equipment, which depends on the use of vacuum pumps, could not yet be used primarily for wastewater sampling (in particular sampling from a certain depth) because these tools do not have the capacity to collect wastewater from a certain depth, are extremely expensive, need a power supply or batteries, and have several separate pieces that in addition to being heavy, occupy much space.

These drawbacks ultimately led to the design and patent (5) (with patent number: 105960) of a mechanical wastewater sampling machine with the sampling capacity from the desired depth, the ability to regulate the sampling angle, and equipped with an altimeter.

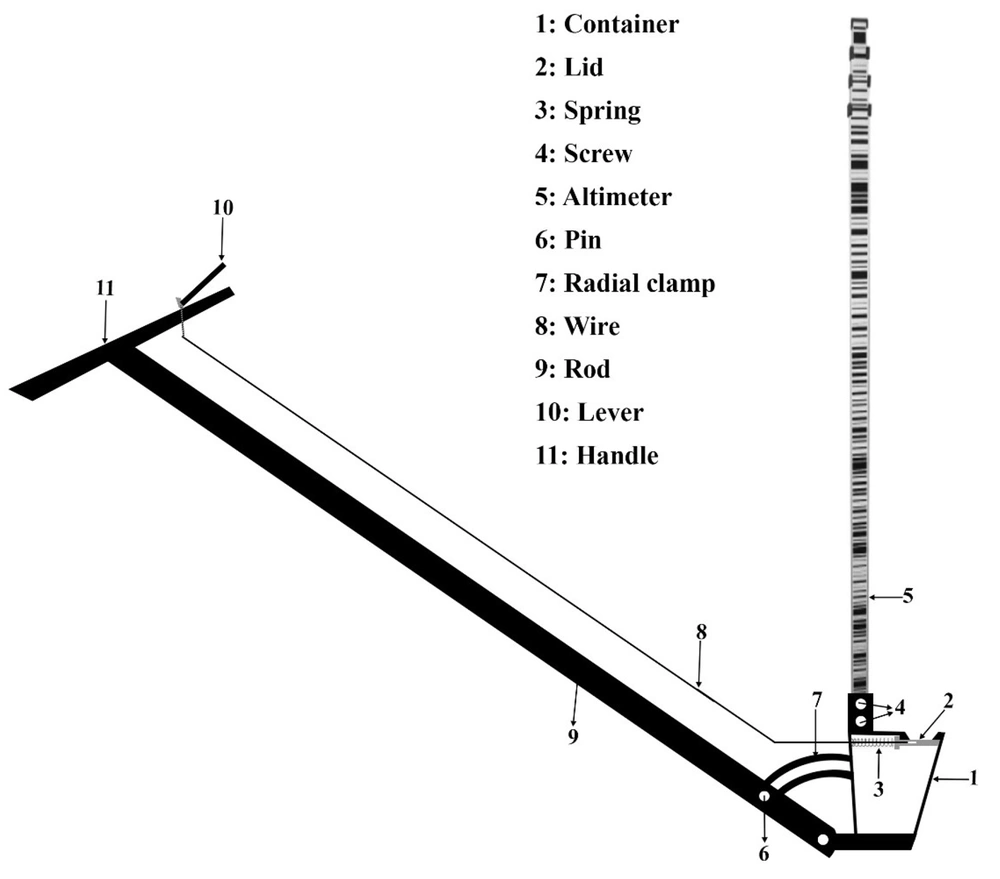

In this tool, first, the container angle relative to the rod (Figure 1, Part 9) is adjusted based on the distance between the worker and the wastewater pond, and then it enters the wastewater. The depth of the sampling container can be controlled by the installed metal altimeter (Figure 1, Part 5), and after placing the container at the desired depth, the lid (Figure 1, Part 2) of the sampling container (Figure 1, Part 1) is pulled and opened by the lever (Figure 1, Part 10) located in the handle (Figure 1, Part 11), and sampling is performed. The lid is rapidly put back into its original position by a steel spring (Figure 1, Part 3) mounted on it.

A wire (Figure 1, Part 8) is connected to the rail lid of the sampler container and is controlled by a lever located in the sampler handle. When pressure is applied to the lever by the worker at the desired depth, the lid is pulled to the opposite side, opened, and filled with wastewater samples at that depth. The lever pressure causes the wire connected to the container lid to be pulled and opened, and lever release causes the door to return to the closed position. The sampler can be pulled up and taken out of the wastewater during this time. When the tool enters the wastewater, the container depth is controlled by the altimeter connected to the sampling container, and when it reaches the desired depth, the lever in the handle is pressed to open the container lid. The altimeter will also be fitted to the container via a screw (Figure 1, Part 4), and the altimeter can be separated in unnecessary situations or transportation.

The rod attached to the container can change the angle via a radial clamp (Figure 1, Part 7). Before entering the container into the wastewater, according to the specifications of the sampling site and for the ease of access and maintenance of worker’s safety and health, the pin (Figure 1, Part 6) attached to the clamp is loose, the angle is adjusted, the pin is tightened, and sampling starts. The sample container is made of PVC plastic, with a volume of 2 L, and is connected to a hollow iron rod (which makes the sampler lighter) through a radial clamp. The length of the rod fixed on the container is 2.5 m. However, because of the installation of pins to hold the sampler rod secured to the radial clamp, the rod can be separated from the container to facilitate transportation into a car.

There is no comparable external or internal example of this product, and it is the first sample of this tool and is innovative. The key positives points compared to other wastewater samplers include:

(1) Ability to sample wastewater from the desired depth without combining with the initial depths (i.e., the specimen is collected exactly from the desired point) through the sliding lid of the sample container.

(2) The angle between the container and the sampler rod is adjustable before entering wastewater. Therefore, the worker can carry out sampling operations at the desired distance from the sewer, where the potential for falling, damage, or contact with pathogenic agents is minimal.

(3) The depth of the sample container immersion into wastewater can be accurately detected by the altimeter installed on the sampler container.

(4) Durable because of the use of PVC in the sampler container.

(5) Being lightweight and easily portable

(6) Requires no power supply

(7) Does not require specific skills to use

(8) No need for complicated and expensive equipment.

Industrialists and wastewater treatment researchers strongly feel the need for this tool. Material availability and high efficiency are prominent and can be used for wastewater sampling.