1. Background

Light is an electromagnetic wave produced when electricity turns into visible light (1, 2) and allows vision and it is one of the most important factors in vision (3-7). Light is used in a wide range of works, from small workshops to great halls of companies and from very precise to very heavy industrial works (8, 9). It is necessary to provide appropriate light with certain frequencies since human eyes are very sensitive to light (2). As a health and safety factor in workplaces, appropriate light is important to provide natural safe work environment and set the best possible psychological mood in workers (10). Appropriate light also reduces work related accidents. Several studies associated appropriate light with the quality of the products (11). Similarly, many studies focused on human health, efficiency, and awareness (12-16). A workplace can be stimulating if a desirable illumination is designed (17). Various factors can affect a desirable illumination, including brightness, light wavelength, light distribution, and surface reflection (18). For example, increasing brightness from the minimum standard of 300 lux to 500 lux can increase efficiency by a mean of 8%. High quality illumination can increase efficiency by 0.2% to 1%, and increasing illumination level from 300 to 2000 lux, can increase efficiency by 15% to 20%. In night shift works, efficiency increase can be 8% to more than 20% (8). On the other hand, a poorly designed illumination can result in undesirable effects such as tiredness, headache, vision disorders, deficiency in recognizing colors and things, accidents, and eye damage (19, 20). Unfortunately, in Iran's industries, illumination is ignored due to financial considerations or lack of proper supervision by authorities (18). Steel industry is considered as a main industry and allows national financial development in various industrial, construction, and building fields (21). In such workplaces many factors affect employees' working condition, one of which is light (22). It is reported that lack of proper illumination is an important factor in work-related accidents (6, 23, 24). According to the primary assessments of the center of workplace safety and ministry of health, 18% of per 10 workers or 16% of employees in most workshops are exposed to undesirable light (18). Based on a study by IESNA, it was observed that accident repeat factor decreased by 30% when illumination increased from 65 to 170 lux (25). Since desirable and proper illumination is an important factor in providing a healthy and safe environment and establish order in workshops, desirable illumination can provide eye comfort, workers health and comfort; increase motivation and satisfaction, precision, efficacy and production, and above all, reduce human error and accidents (8, 11). Due to these reasons, light quality should be enough to ensure proper eye function to perform related tasks (26).

2. Objectives

Due to the importance of illumination level in reducing accidents and increasing efficacy and safety, the current study aimed at evaluating actual level of illumination in units of a steel company in Ahvaz, Iran and designing and performing desirable illumination plan to achieve the above said goals.

3. Methods

The current descriptive cross sectional study was conducted in a number of Kavian steel company units in Khuzestan province including roller cutting workshop, manufacturing and renovation workshop, and the hall 25 (in which turning andwelding are done) in 2016. In the current study, one-sample test was used to compare average illumination intensity and standard levels and analyze the data. To assess illumination intensity in Kavian steel company units, general lightning, lighting design position, types of lamps, their places, and the number of doors and windows were examined and studied. The network method was used to distribute illumination in the studied places (1, 3). In this method, following the preparation of a simple map of the studied place, the area was divided into equal squares. In closed spaces, the dimension of every square was determined; based on the dimensions, 3 to 10 meters, considering the studied halls dimensions, a total of 107 checkerboard places were acquired in order to measure illumination intensity. The center of every checkerboard place is a measurement station that lightness intensity in each of them was measured in horizon level (in 1-meter height) and registered on the checkerboard plan. Lightness levels in the center of per station with average illumination in every unit were calculated and compared to the standard values. The proposed standard for the considered units, in accordance with the values provided by the specialized committee of the occupational safety and health standards, was determined 300 to 500 lux that due to elegance and focus on doing the work, the maximum level of the standard (500 lux) was considered to compare with the amounts of measured luminance (27). TES-1339 calibrated Lux meter made in Taiwan was used to measure the illumination intensity in all the units of the company (28, 29). To calibrate the device and ensure the validity of measurements and considering the fact that this device used a photoelectric receiver and the receiving cell was sensitive to visible light, point zero calibration technique was used for external calibration. The measurements were done on December 21, coinciding with the first day of January between 8 to 10 and 14 to 16 because in the early hours and the end of the day, natural light intensity on the surface of the horizontal and vertical level is at its minimum (27). To compare the amount of measured lighting intensity (natural and artificial lighting) with the standard levels, the technical committee policies based on the occupational safety and health, and Iranian occupational safety and health announced 2016 were used, which were according to the standards of lighting engineering association of North America (30). To calculate the number of lamps in the lumen illumination method, the room index was needed (Kr); coefficients of reflection (coefficient of reflectance floor [ρfc], coefficient of reflectance ceiling [ρcc], coefficient of reflectance walls [ρw]); the maximum allowed distance between the lamps (MH), depending on installation height from floor lamps or ceiling to floor height and distribution curve of the lamp and sort reflector; coefficient of utilization, maintenance factor; and unit area and luminous flux of each lamp (IES tables). Then, thenumber of lamps can be calculated by Equation 1:

Where N is the number of lamps, Qt is total luminous flux, and QL is luminous flux of lamps.

To determination the total luminous flux and the average illumination, Equation 2 was used (3, 20):

Where Qt is luminous flux of lamps (lumen), MF is maintenance factor, CU is coefficient of utilization; where A is unit area (m2), Eav is the average illumination, and LUX (lumen/m2). Also, the distance between the lamps (X) with length (L) and width (W) and the number of lamps (N) were calculated and determined (3, 7).

4. Results

General illumination in Kavian steel company units was provided by windows and doors as natural sources and high-pressure mercury lamps as artificial light sources, which were not favorable in terms of installation type and steady illumination distribution. Kavian steel company consists of diverse units to manufacture industrial products. Achieved results from the measurement of illumination intensity in several units (the hall 25, manufacturing and renewal workshop, and roller cutting workshop) of the company presented by standards values (300 to 500 lux) were compared by the expert committee for health and career standards. The results indicated that averages of illumination intensity in the hall 25 and manufacturing and renewal workshop (respectively 344.43 and 262.05 lux) were less than the standard limit (500 lux) and in the roller cutting workshop (621.35 lux) was more than the standard limit (Table 1).

| The Studied Units | Standard | P Value | Mean ± SD | Min - Max | Median | Mode |

|---|---|---|---|---|---|---|

| Hall 25 | 500 | ≤ 0.05 | 344.43 ± 166.42 | 110 - 1150 | 335 | 250 |

| Roller cutting | 500 | ≤ 0.05 | 621.35 ± 240.04 | 92 - 1060 | 665 | 665 |

| Manufacturing and renewal | 500 | ≤ 0.05 | 262.05 ± 65.62 | 100 - 320 | 300 | 320 |

Illumination in the Halls 25, Roller Cutting and Manufacturing, and Renewal Workshops

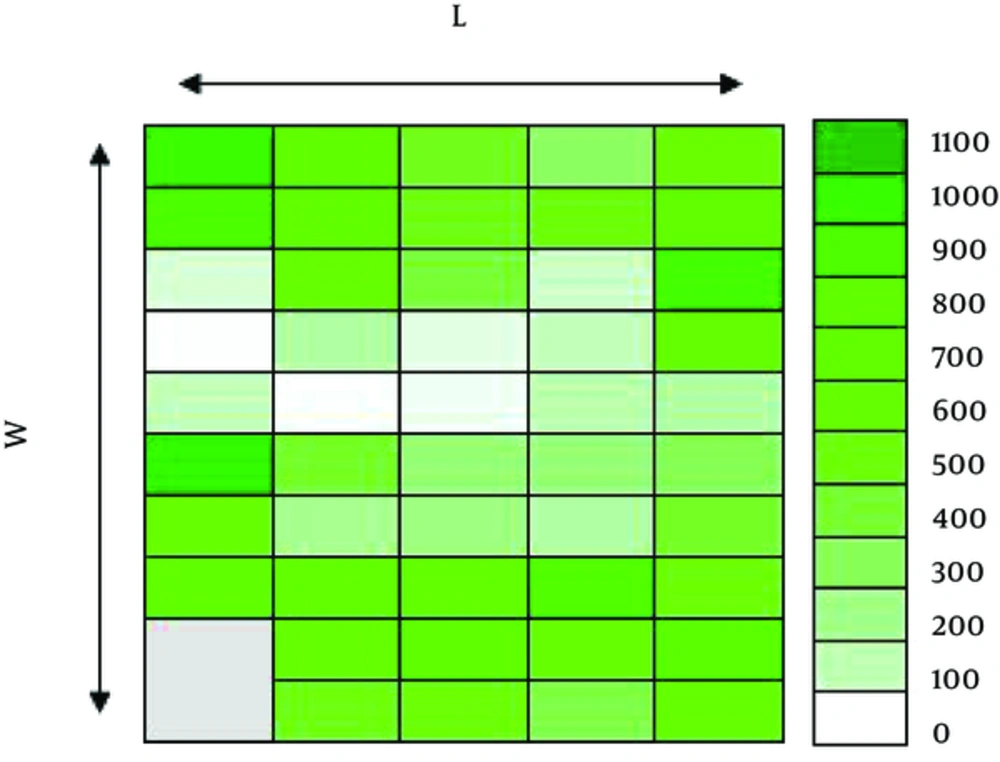

4.1. Unit No. 25

Characteristics of unit 25 in which welding, lathing, and mechanical operations are running were inclined roof with lateral height of 8 m and highest height of 10 m, workshop dimensions of 100 × 20 m, roof made of Iranite and dark color, old floor tarmac, and bare brake walls. This unit had two 3 m-wide doors and 54 high-voltage mercury lamps with a 9 × 6 arrangement. Lamps were notproperly cleaned and 12 of them were not working. The hall was divided into 50 10 × 4 m squares, based on its dimensions. Given the achieved results (Table 1) showing that average illumination intensity (344.43 lux) was less than the standard limit (500 lux), light distribution in the hall 25 was unsuitable (Figure 1). Thus, redesigning due to inadequate view and dazzling in some areas was essential to increase efficiency and create a secure career environment. Therefore, the formulas and relations related to the lumen method were applied to acquire the values of space index variables for direct light, coefficient of utilization (given reflection coefficient of ceiling and walls), light power of all lamps (high-pressure mercury), light power per lamp, the number of required lamps (relations 1 and 2), and design criteria control (Table 2). High-pressure mercury lamps were used to redesign. This group of lamps is extensively applied in large places, which do not need high coloring, such as warehouses, industrial production halls, and stadiums with a 6 to 12 meter height (30). Since the installation of high-pressure mercury lamps were focused on several lines, 84 lamps should be put in four 21-one lines. In the installation process, it should be noted that the height of the lamps be 7 m form the floor (Table 3).

Calculating Illumination Based on the Lumen Method, Using Room Index

| Title | Value | ||

|---|---|---|---|

| Manufacturing and Renewal | Roller Cutting | Unit No. 25 | |

| QL, (lux) | 10400 | 260000 | 10400 |

| NL, w (lamp) | 82 | 70 | 15 |

| Eav, lux | 300 | 500 | 300 |

| X, m | 5 | 2.85 | 5 |

Calculations of High-Pressure Mercury Lamps

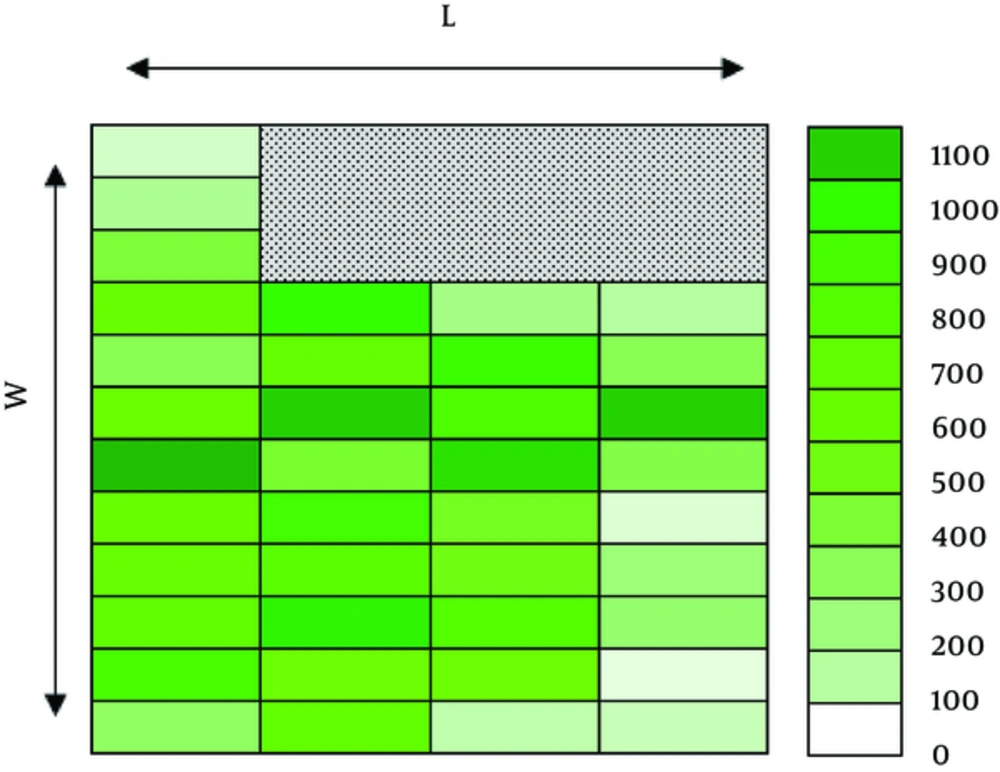

4.2. Results from Roller Cutting Workshop

The dimensions of the workshop were 20 × 80 m and its inclined roof had a lateral height of 8 m and maximum height of 10 m. The roof was made of dark Iranite, floor was tarmac-covered and walls were made of bare bricks. From the 50 existing high-voltage mercury lamps, 12 were not working. A number of fifty 5 × 6.5 m measurement stations were specified. Standard degree of illumination intensity proposed for cutting big pieces was considered 500 lux. Given the average illumination intensity in roller and cutting workshop (621.35 lux) which was more than standard limit (Table 1) and due to the possibility of dazzling and unsteady dispersion in illumination distribution (Figure 2), this workshop should be redesigned. Hence, the Lumen method (relations 1 and 2) was utilized to obtain illumination intensity and the number of the lamps (Table 2). Since the method of lamp installation was in-point form and several lines, the number of high-pressure mercury lamps was considered 84; therefore, the lamps were put in 7 twelve lines. In installation, the lamps height from the floor should be 7 m (Table 3).

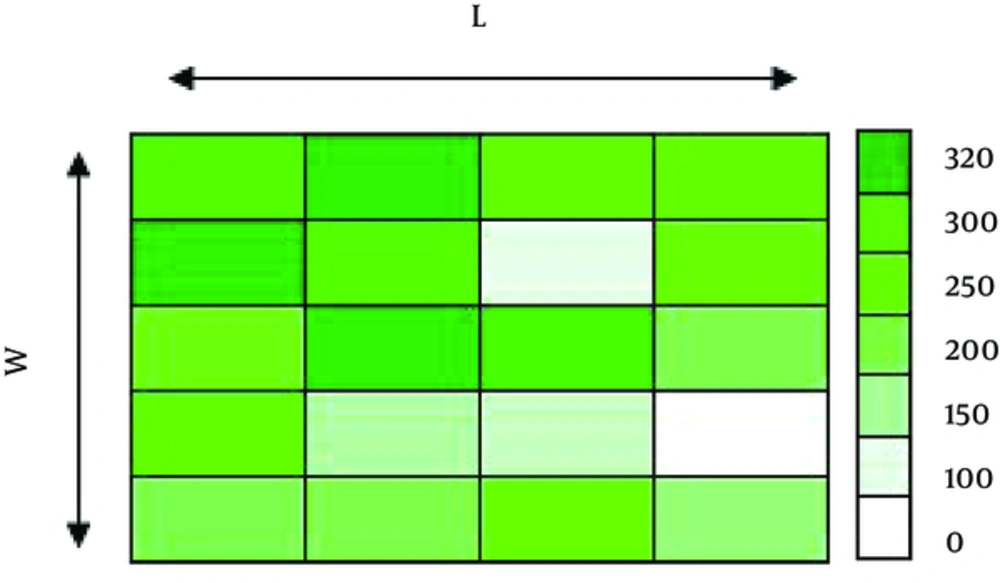

4.3. Results of Manufacturing and Renewal Workshop Measurement

Measurements in this workshop showed that its dimension was 20 × 15 m and the roof had a lateral height of 8 and maximum height of 10 meters. Lamps were installed at 6 m from the floor. This hall had 16 high-voltage mercury lamps. The measurements in this workshop indicated that dimensions were 20 × 15 m, 8 m side-height, and 10 m height and that lamps height from the work level was about 6 m (Table 2). This workshop had 16 high-pressure mercury lamps. According to the workshop area, 20 stations with 4 × 5 m dimensions were determined to measure illumination degree, and the standard degree of illumination intensity was considered 500 lux. Given the results achieved from average illumination intensity (262.05 lux less than standard limit) and unsteady dispersion illumination distribution (Figure 3), lighting intensity to work safely was not sufficient in this workshop (like the hall 25). Therefore, using the Lumen method (relations 1 and 2), illumination in this workshop was redesigned (Table 2). Since it was focused to install high-pressure mercury lamps in the point form and several lines, 15 lamps can be put in 3 five-one rows (Table 3).

5. Discussion

The current study aimed at measuring the illumination degree in Kavian steel company units in Ahvaz. Light is one of the electromagnetic waves produced from changing electric energy into visible energy by human eyes (1); it is a powerful exogenous factor in controlling many behavioral and physiological processes (31). Good lighting in the industrial environment is considered as a health and safety factor with a high impact on human health, efficiency, and level of consciousness and can also be considered as an effective motivation for personnel (10, 12, 17). According to the measurements stated in the tables, it was observed that measured average illumination in the hall 25, roller cutting workshop, and manufacturing and renewal workshop were 344.43 ± 166.42, 621.35 ± 240.04, and 262.05 ± 65.62 lux, respectively. Averages of illumination in the hall 25 and manufacturing and renewal workshop were less than the standard limit (500 lux) and in the roller cutting workshop it was more than the standard limit (500 lux), which was in accordance with the results of the studies by Ranjbaran et al. (10) and Golmohammadi et al. (32) in which illumination intensity degree in many measured stations was also less than the standard limit. About 52% of the total stations in the hall 25 as well as 17% in roller cutting workshop, and 55% in the manufacturing and renewal workshop were in standard limits, and the remaining stations were in a higher or lower scope. In another study by Espinoza et al. at the University of Costa Rica it was found that half of the measuring stations were poorly lit (33). Illumination more than the standard limit does not have a favorable effect on efficiency and it wastes energy and creates brightness in the environment. In other words, illumination does not increase the efficiency after reaching a defined limit, and the role of natural day light entering through doors and windows cannot be ignored. Since the level of illumination intensity in units was unfavorable according to the measurements, artificial illumination system was redesigned, given their specifications (Table 2) and using the Lumen method (relations 1 and 2); it was in accordance with those of Shafieimotlaq et al. and Rangkooy et al. in which lighting was redesigned due to uncomfortable illumination (3, 22). Finally, considering the conducted calculations, 84 160-W high-pressure mercury lamps in four 21-one rows, 84 400-W mercury lamps in 7 ten-one rows, 15 160-W mercury lamps in 3 five-one rows were needed in the hall 25, roller cutting workshop, and manufacturing and renewal workshop in order to provide favorable illumination in the units, respectively (Table 3).