1. Background

Every year, there are numerous chemicals being supplied to the world markets that add to the currently several thousand chemical substances used worldwide; therefore, in many workplaces, exposure to chemicals and their consequent associated risks does indeed exist and is increasing as well (1, 2).

According to the statistics provided by the World Health Organization, approximately four million people worldwide are involved in different chemical industries and activities annually and a million of these people will eventually either die or become disabled due to unsafe occupational exposure (3).

Laboratories are prominent workplaces that include a share of these chemicals. Employees in laboratories are often exposed to acids, strong bases, carcinogens, flammable materials, and explosives delivered via respiratory and dermatological routes (4). The biggest challenge ahead, therefore, is the hazards that do not entail the prevention of instant consequences. However, no suitable steps have yet been taken for the control of such unknown hazards (5).

Negligence in controlling the dangers of chemicals can lead to disease, physical damage, and even death, as clearly evident in the numerous incident reports taken by news sources, universities, and research centers (6).

So far, no studies have yet been conducted to investigate the health status of laboratories at the Shahroud University of Medical Sciences.

2. Objectives

This study is conducted to assess occupational exposure to dangerous chemicals and to evaluate occupational incidents at the University’s health centers.

3. Methods

3.1. Study Population

In this descriptive-analytical study, the population of the study consisted of employees working in various laboratories at Shahroud University of Medical Sciences, Semnan, Iran in 2016 - 2017, which included two hospitals, one health clinic, and one health center laboratory in the city.

3.2. Data Collection

A demographic questionnaire was used to collect individual and organizational information. Upon initial coordination with the health centers, the researchers were referred to these centers.

3.3. Semi-Quantitative Assessment Risk Method in Exposure to Hazardous Chemicals

In this study, the methodology presented by the Department of Occupational Safety and Health-Ministry of Human Resources (DOSH) was used (7, 8) (Supplementary File Appendix 1). Since the semi-quantitative risk assessment method refers to ranking and prioritizing risks, by using this method, control measures can be conducted based on exposure factors and the reduction of the exposure index for the compounds studied as well as the reduction of risks by eliminating or substituting the substance with a less hazardous substance.

3.3.1. Hazard Rating (HR)

In general, the risk assessment equation, when examining chemicals, is the level of exposure to chemicals times the hazard rating of the chemicals. Thus, these two parameters were determined to assess the risk. Upon identifying the chemicals used in the experiment, the next step was to determine the toxicity of risks of using these substances. Hazard ratings were determined by the two methods below:

- Through toxic effects of the chemical substance.

- Through acute toxicity of chemical substances.

3.3.2. Exposure Rating (ER)

Exposure rating was determined using the three parameters of exposure frequency, exposure duration, and intensity or magnitude of exposure.

Based on exposure frequency or exposure duration and exposure magnitude, exposure rating was determined.

In cases where occupational disease due to exposure to dangerous chemical substances was reported or approved, the value of exposure rating five was considered.

3.3.3. Semi-Quantitative Risk Assessment

Risk levels were derived by considering hazard rate and exposure rate of dangerous chemical substances via the Equation 1:

- ER: exposure rate based on a scale of 1 to 5

- HR: hazard rate based on a scale of 1 to 5

In order to place the risk level in the range of 1 to 5, the second root was used.

If the calculated risk level was not a valid integer, it was summed up to the closest higher integer.

3.3.3.1. Risk Rating

Exposure risk to chemical substances are determined at any employment status and rated using Table 1:

| Risk Level | Ranking-Action Level |

|---|---|

| ≥ 2 | Low: control operation |

| 3 | Medium: risk control in the near future |

| 4 | High: urgent action to control the risk |

| 5 | Very high: stop work and risk control |

3.4. Ethics Statement

This research was confirmed by the Shahroud University of Medical Sciences with registration reference of IR.SHMU.REC.1395.53. The study was approved by the Ethics Committee of Shahroud University of Medical Sciences, Shahroud, Iran. Informed consent was obtained from all participants. Privacy and confidential issues were considered throughout the study. The study excluded those respondents who were not interested in being involved in the survey.

3.5. Statistical Analysis

Descriptive statistics and chi-square tests were used to assess the relationship between occupational incidents and independent variables. Also, Microsoft Office-Excel 2010 and SPSS19 at 0.05 significant level was used for data analysis.

4. Results and Discussion

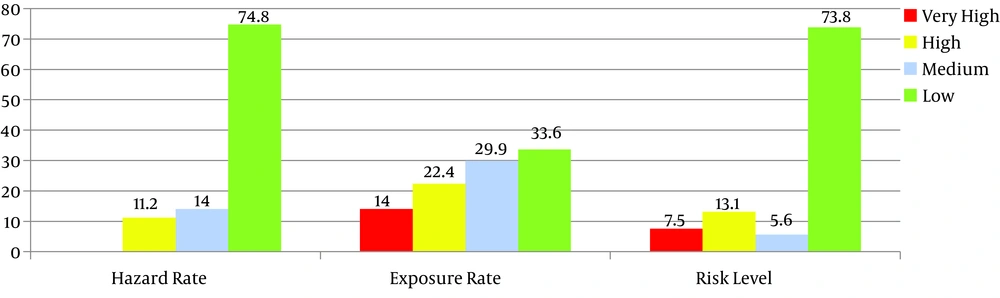

According to the final results, 6.6% risk of exposure to chemicals used in laboratories were of very high risk (according to Table 1 these exposure should be stopped quickly and run risk control), 13.21% were of high risk, 5.66% were of moderate risk, and 74.53% were of low risk.

At a total of four centers; 21 chemical substances (from 106 highly consumed chemical substances) were identified within four and five risk levels (although some of these substances were used jointly at a few centers). Approximately 19.81% of assessed laboratories had significant exposure risks.

The percentage of occupational exposure to hazardous chemicals is shown in Figure 1.

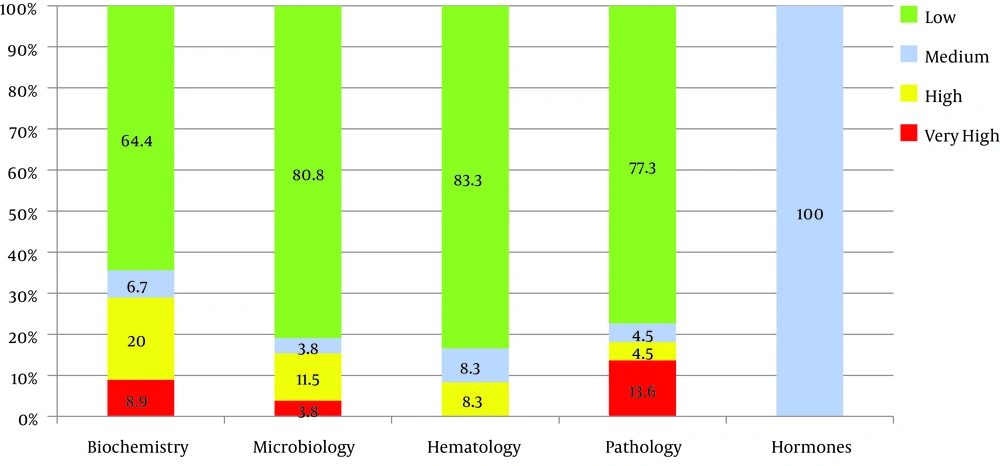

In Figure 2, the frequency of occupational exposure to chemicals in the centers is presented separately from laboratories.

The most dangerous substance used in laboratories is Formalin 10% solution (Formaldehyde solution), which consists of two formaldehyde and methanol chemical substances. Formaldehyde is classified as an A1 carcinogen chemical substance (9). In a study conducted by Jahangiri and Parsarad (10) on subjects exposed to chemicals in Iran’s petrochemical industry, similar results were reported.

Other hazardous and high-risk chemicals used in the pathology and biochemical laboratories were substances such as chloride, ethanol, permanganate, xylene, oxygenated water, and sodium disulfide, which according to toxicological information, had a hazard rating of three and four (11).

According to Table 2, there was a significant difference between the status of passing the training period and occupational safety and health retraining in the last year (P value = 0.03). Further, the willingness of employees to use personal protective equipment (P value = 0.041) is reported along with the experience of a work accident. Those employees who did not interfere with occupational safety and health education and training courses in the last year, as well as those employees who were less willing to use personal protective equipment, were significantly affected by occupational accidents.

| Variables | Experience of Occupational Accident | χ2 | P Value | |

|---|---|---|---|---|

| Yes | No | |||

| Education | 1.974 | 0.16 | ||

| Associate degree | 8 (26.67) | 2 (6.67) | ||

| Bachelor’s degree and higher | 10 (33.33) | 10 (33.33) | ||

| Training and retraining in the last year (occupational safety and health) | 5.154 | 0.030 | ||

| Yes | 5 (16.67) | 9 (30) | ||

| No | 13 (43.33) | 3 (10) | ||

| The desire to use personal protective equipment during work | 4.135 | 0.041 | ||

| Yes | 4 (13.33) | 10 (33.33) | ||

| No | 14 (46.67) | 2 (6.67) | ||

Results of the study showed that the education level of subjects did not have a significant effect on occupational incidents (Table 2). Various studies have shown that incidence rate among employees with lower education levels has been higher (12), however, for this study, given the fact that the target group consisted of technicians and experts in medical diagnostic laboratories, all of whom were educated, this issue was not significant while in other studies that were often conducted at industry level, and education levels were either diploma or lower; this comparison was assessed among individuals that have higher and lower education levels than a diploma.

Also, the results indicate that taking work-related training courses has a significant role in reducing occupational accidents (13). It is not surprising that awareness can play an effective role in modifying the behavior of individuals (14, 15).

In this study, it was found that reluctance in using personal protective equipment (PPE) is effective in the occurrence of occupational accidents for workers (16, 17).

From this study, it can be concluded that approximately 19.81% of the assessed laboratories have significant exposure risks. Therefore, it is suggested that these dangerous chemical substances (risk rating = 4 or 5) should be determined on a specific form including the name of the chemical substance, the chemical composition, the name of the tests that the chemical substance may be used in, the TLV, as well as chemical handling instructions, locations where the substances are stored and maintained Finally, the necessary training is provided on employee risk management. Also, it is recommended to work under ventilation hood and use of appropriate PPE.