1. Context

Food is essential for the life of living organisms, so its packaging and preservation and prevention of premature spoilage are of great importance. Food production includes processes such as growing, harvesting, and processing. In order to have food that can be eaten and stored for a long time, we need good packaging and storage to prevent spoilage and damage (1). Food products such as vegetables, fruits, meat, and dairy products are highly susceptible to spoilage. Bacterial growth in food products can cause contamination, food waste, and transmittable diseases. Bacterial growth in food products can be reduced by adding antimicrobial agents to food packaging (2).

In developed countries, about 20 to 25 percent of harvested food crops spoil during transportation due to the presence of bacteria after the process. In some countries, the situation is even worse due to the lack of proper transportation infrastructure and storage facilities (3). Changes occur, including acidity, softening of the texture, changes in sensory properties, and weight loss of the food (4, 5). Today, petroleum-derived polymers including polyethylene, polypropylene, etc. are used in food packaging (6). Different parts of plants contain compounds such as caracrolein, limonene, thymol, eugenol, etc., which are extracted from the plant by different methods (7, 8). Food packaging with compounds that have antimicrobial and antioxidant properties can increase the quality and shelf life of food products (9).

Food packaging is a new way to reduce food waste, which increases food safety by protecting it with antimicrobial and chemical agents (6). Today, biodegradable coatings are produced from natural materials because the use of unusable materials has caused many environmental and unsanitary problems (8). Food packaging is of great importance because it is recyclable and environmentally friendly (10). Food packaging prepared with essential oils and plant extracts has very high antioxidant and antimicrobial properties, which increases food quality and increases the safety of accompanying products (9). Edible coatings can be a very suitable alternative for product packaging because they extend the shelf life of food products (11). Choosing a natural antioxidant can replace a synthetic one. Synthetic antioxidants have caused widespread side effects, including digestive problems and skin allergies (12).

Phenolic acid and flavonoid compounds cause oxidative stress and inactivate enzymes that are necessary for bacterial growth in food, reducing microbial growth and preserving food (13). Various plants are used to make coatings. Green tea plant contains many active compounds including catechins, tannins, saponins, and alkaloids, which have strong antimicrobial activity against foodborne microorganisms (14). This plant is a very strong inhibitor of Bacillus cereus, Escherichia coli, and Staphylococcus aureus (15). Grape seed extract is another product used in the food industry. This compound also contains flavonoids, tannins, and polyphenols, which have high antimicrobial properties. This extract is approved as a permitted additive in the US food and pharmaceutical industries (16).

Rosemary is another plant that has been used in food packaging. This plant contains polyphenolic compounds that have shown high antimicrobial activity (17). This plant increases the lifespan and shelf life of perishable materials (18).

2. Evidence Acquisition

We conducted a thorough investigation by carefully examining various databases, including PubMed, Scopus, Web of Science, and the Cochrane Central Register of Controlled Trials, until September 2024.

3. Results

Ghasemlou et al., which investigated the biofilm of biodegradable antimicrobial packaging based on starch particles, showed that the tensile strength decreased and the elongation increased significantly. The presence of edible essential oils on the inner and outer surfaces of the film confirmed that this explains the decrease in water vapor permeability in the lipid-containing film (19). Gheble and Sever, the application of chitosan edible coating containing propolis extract and thyme essential oil on the quality and shelf life of chicken meat at refrigerated temperature was investigated. The results showed that coatings prepared from chitosan containing propolis extract and thyme essential oil improved the quality of chicken breast meat samples for 16 days in a refrigerator at 4°C and increased the shelf life of chicken meat in a refrigerator at 4°C (20). Ebrahimian et al., the effect of gelatin coating containing aqueous orange peel extract (Citrus sinensis) on increasing the shelf life of rainbow trout meat during storage at refrigerated temperature was investigated.

The results showed that gelatin coating with different levels of orange peel extract had a positive effect on increasing the shelf life of fish meat and that these compounds could be used together to increase the shelf life of protein foods (21). Soiklom et al., who investigated the development of bioactive edible films and coatings derived from Spirogyra sp. extracts to increase the shelf life of fresh produce, showed that the film transparency and water vapor permeability were reduced by 13% and 50%, respectively, compared to the control sample (22).

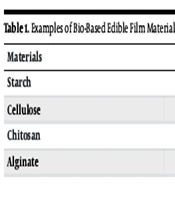

In the study by Gharghavi and Roomiani, who investigated the effect of edible coating of whey, thyme, and oregano essential oils on the microbial and chemical quality of Vanami shrimp, the results showed that the control treatment had the highest microbial load and with increasing the level of essential oil, the microbial load decreased significantly and the lowest microbial load was related to treatments 4 and 5. Adding essential oil at two levels of 1 and 3% increased the storage time of shrimp in refrigerated conditions (Table 1) (23).

4. Discussion

Various plant materials are used in the manufacture of the coating.

4.1. Polysaccharides

Polysaccharides are abundant carbohydrates found in plants that are widely used to make edible films for food packaging. Cellulose is one of the abundant polysaccharides in plants that has various properties including strength and heat stability (28).

4.2. Protein

Soy protein, wheat gluten, and casein are among the vegetable proteins that have good functional properties for making edible films (29).

4.3. Lipids

Lipids derived from plant sources have also shown promise in the development of plant-based materials and edible films. Vegetable oils and fats, as well as wax-based materials, are notable examples in this category. Vegetable oils and fats, such as vegetable oils derived from soybean, corn, sunflower, or palm, can be used in the formulation of edible films.

In a study conducted on the effect of plants in treating heart disease, the results showed the great effect of plants (30). Another study showed that medicinal plants and their active substances are effective in the treatment of polycystic syndrome (31). Various studies have shown excellent effects of plant extracts on foodborne pathogens (32).

4.4. Conclusions

Edible coatings are widely used in the food industry. Edible coatings based on essential oils and plant extracts can exhibit better and higher antimicrobial properties. Therefore, the use of this type of coating is recommended for longer shelf life in the food industry.