In wastewater treatment plants (WWTPs), operators and researchers often focus on evaluating the effectiveness of a treatment process relative to a certain depth (1). The validity of the results obtained from wastewater analysis mainly depends on the accuracy of the sampling technique (2).

Currently, WWTPs use conventional methods of sludge sampling, in which a shovel-like container connected to a rod is immersed in the wastewater sedimentation pond. As the container is completely open at the beginning, in the first moment, the container is filled with liquids from the upper depths of the wastewater, and increasing the depth of the sampler does not alter the volume and composition of the collected wastewater sample (2, 3). In this type of sampling, the collected sludge is a combination of supernatant fluid and a very small quantity of sludge and settled material.

On the other hand, assume that in this type of sampling, it is possible to rub the shovel-like container on the bottom of the pond and fill it with a suitable amount of sludge. Again, because the container is not closed after taking the sample, when the container sludge is pulled up from the depths of the settling pond by the operator, supernatant liquid at higher depths enters the container and makes a great change in the initial composition of the collected sludge.

The relatively deep depth of wastewater treatment ponds may pose a serious health risk to workers and WWTP operators who intend to take sludge samples. In addition, due to the potential for pathogen transmission via direct contact or sewer droplets, it is necessary to place the sampler worker at an appropriate distance from the wastewater system so that the probability of falling and transmitting pathogens is minimal (4). This issue has always created anxiety and concern among researchers and workers at WWTPs.

Currently, in sludge sampling, the depth is estimated. The operator plunges a rod of a certain length, connected to the sampler container, into the sewage to reach the desired depth. This is one of the basic problems of conventional sampling because the inaccurate collection of sludge or sewage at the desired depth leads to incorrect results.

In our previous study, a tool was only designed to collect wastewater and could not collect sludge (2, 5). As a result, the above problems led to the design and patenting (with patent code: 107318) of an innovative sampler to collect sludge and sediment from the WWTP ponds (6).

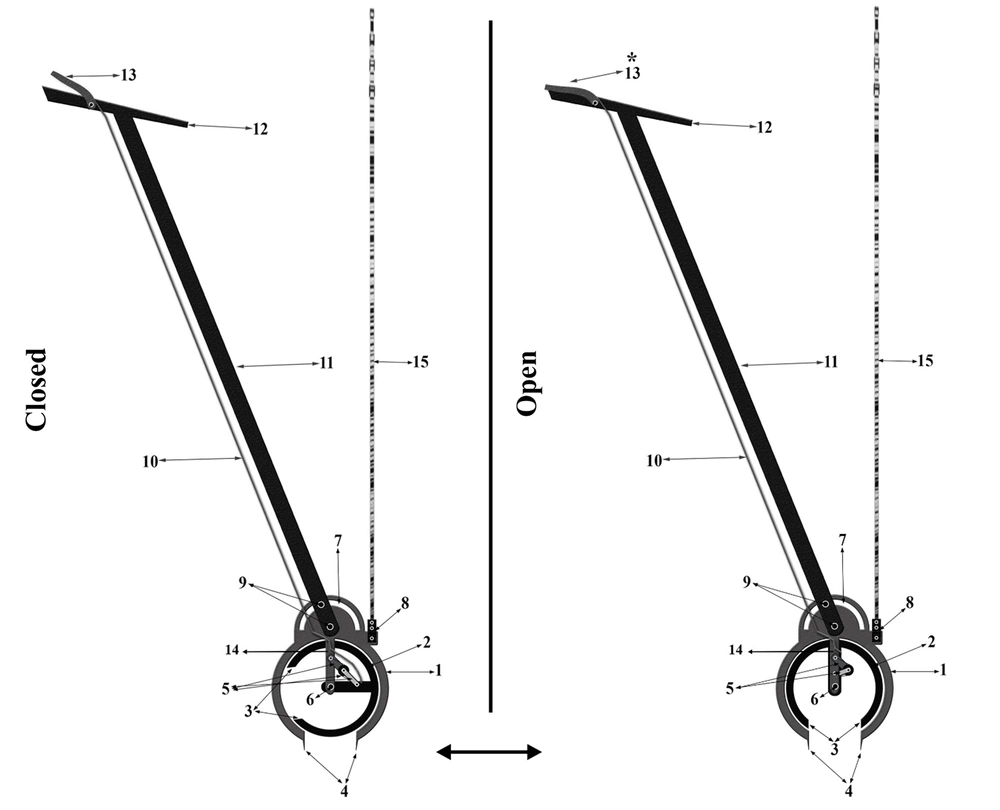

This invention consists of two concentric PVC cylinders: a small cylinder (Figure 1, Part 2) inside a large cylinder (Figure 1, Part 1). The internal cylinder can rotate mechanically to open and close (Figure 1). A metal rod (Figure 1, Part 11) is connected to the outer cylinder, the angle of which can be modified using the axial arm (Figure 1, Part 7). Before putting the sampler into the wastewater pond, based on the sampling site, accessibility, and maintenance of the safety and health of the worker, the screw (Figure 1, Part 9) connected to the axial arm is loose, and its angle is adjusted. Then, the screw is tightened, and the sampling process starts. The rod can be detached from the container to facilitate transportation. Also, depending on the application and the required sampling depth, rods of different lengths can be designed and connected to the sampler.

The inner cylinder is movable, and the outer cylinder is fixed. The inner cylinder is movable by the pin (Figure 1, Part 6) on the axis of the outer cylinder (Figure 1, Part 14). The inner cylinder is attached to the lever (Figure 1, Part 13) in the sampler handle (Figure 1, Part 12) by a wire (Figure 1, Part 10). The inner cylinder is a container for carrying sludge and sediment and has a volume of 3.5 liters. The inner and outer cylinders have an inlet that allows the sludge to enter the inner cylinder at the desired depth. The inlet of the outer cylinder has a blade-shaped outer edge (Figure 1, Part 4), which makes the sludge enter the inner cylinder after the sampler comes in contact with the bottom of the pond. When the worker has not pressed the lever, the wire is not pulled, and the inlet of the inner cylinder (Figure 1, Part 3) is not parallel to the inlet of the outer cylinder. In this case, the entrance of the sludge into the inner cylinder is completely closed.

An altimeter (Figure 1, Part 15) is installed on the outer cylinder by a clip (Figure 1, Part 8), through which the depth of the immersion of the sampler cylinder into the wastewater is controlled. The index can be completely separated when not required or during transportation. When the sampler is positioned at the desired depth in the wastewater pond, the worker presses the lever, and the inner movable cylinder rotates counter-clockwise because of its connection to the wire. In this case, the inlet of the inner cylinder and the outer cylinder are aligned. The worker must maintain this state for a few moments so that the sludge enters the inner cylinder through the inlet and the blade of the outer cylinder. At this moment, when the worker releases the lever, the inner cylinder rotates clockwise with the force of the spring (Figure 1, Part 5), and the inlet of the inner cylinder is not in line with the inlet of the outer cylinder. In this case, the entrance of the outer cylinder is completely closed, and the inner cylinder carries the sludge, which is kept isolated in the inner cylinder. At this moment, the worker can take the sampler out of the wastewater pond and, by pressing the lever, empty the sludge into the laboratory containers.

The need for this novel sampler is felt in the engineering science of wastewater systems. This sampler is lightweight and does not require electrical power. It can be widely used to sample sludge and sediments at the desired depth in WWTPs.

In this sampler, before and after collecting the sludge sample, the sludge container is completely closed so that when the sampler enters the wastewater pond, the volume of the container is not occupied by the upper liquids in the initial depths. Also, the upper wastewater should not disintegrate and mix with the collected sludge when removing the sampler from the pond.

The altimeter can recognize the depth of immersion of the sampler into the wastewater. Also, the angle of the sampler rod can be adjusted before it enters the wastewater pond to allow the worker to sample at a suitable distance from the pond so that the probability of falling and being exposed to pathogenic agents of wastewater is minimal.