1. Background

Industrial wastewater contains a diversity of impurities and therefore, its treatment constitutes a special task. Release of industrial effluents to the environment have aroused serious concerns all over the world for the toxic effects of effluents, such as mutagenic and carcinogenic action to aquatic biota and humans or simply almost non-biodegradable materials in these effluents (1, 2).

Nowadays, various physicochemical and biological methods have been developed to reduce chemical’s pollution and hazards. Among these methods, biological treatment is perceived as an attractive method owing to its comparable low costs and easy operation (3, 4). Nevertheless, the varying treatment efficiency and land area requirements have paved the way for other treatment techniques to be employed in chemical industrial wastewater treatments. Attempts to upgrade biological treatment systems or intensify the separation process, e.g., by membrane separation of the sludge, have been technologically successful (5, 6), however, not widely exploited due to the operational problems, additional energy demand, and high capital and maintenance costs.

During the last two decades, intensive research in the field of biological wastewater treatment has successfully resulted in engineering microbial structures in activated sludge to allow microorganisms to form a stable granular sludge with spherical shape and clear boundaries instead of conventional flocculent sludge (7). Such a form of sludge makes gravity-based separation a compact process that could be integrated inside the treatment unit and greatly reduces land area requirements and costs (8). The process is generally completed in sequencing batch reactors (SBRs), with a cycle layout designed to select for fast settling microbial aggregates and a frequent repetition of feast and famine conditions take place. Such a highly dynamic feed regime results in the growth of stable and dense granules as well as induction of specific metabolic pathways required in the biodegradation of non-readily biodegradable substrates (9-11).

In the present study, we attempted to develop and make use of aerobic granules to improve the process performance of a laboratory scale SBR treating synthetic wastewater containing ethylene glycol (MEG) as a model industrial compound. MEG (C2H6O2), a solvent widely used in industry for the preparation of polyesters, resins, wetting and plasticising agents, coolant additives, and the formulation of printing ink (12), with ~ 1.39 g COD/g MEG, by itself is a major pollutant in industrial effluents.

2. Objectives

The objective is to develop a new cost-effective technique for treatment of chemical industry effluents. The possibility and effectiveness of this new enhanced biological treatment system were determined through mean diameter, relative hydrophobicity, sphericity, and SVI5 of aerobic microbial aggregates.

3. Methods

3.1. Experimental Setup and Strategy of Operation

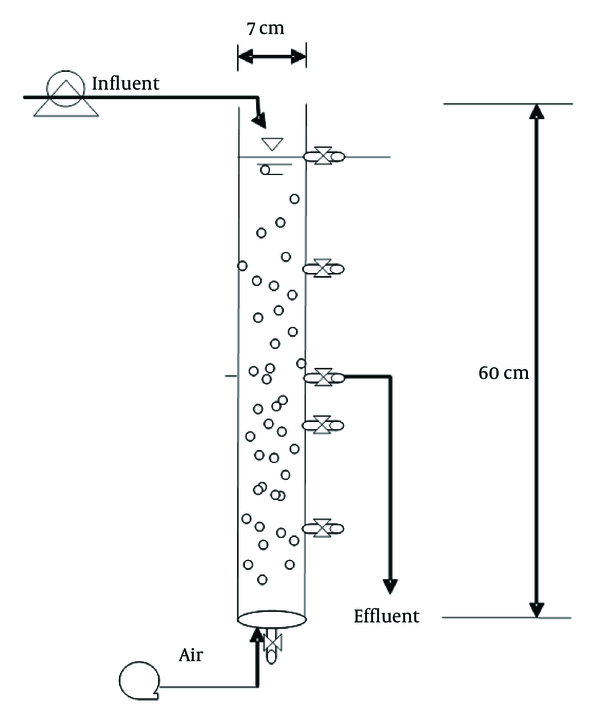

All the experiments were conducted in a laboratory-scale columned type SBR with a working volume of 2 L. The reactor was made of glass with a height, inner diameter, and height to diameter (H/D) ratio of 60 cm, 7 cm, and 8.5, respectively. A porous air stone was placed at the bottom of the reactor for aeration and mixing at an airflow rate of 2 - 4 L/min. It was fed with synthetic wastewater and operated under the sequential batch mode of 4 cycles per day. Phase duration and operating conditions of SBR are given in Table 1. The effluent withdraw was done through sampling ports placed in the height of the reactor at pre-determined distances to achieve various exchange ratios of 25% to 75%. A programmable logic controller (PLC) (Omron, Japan) controlled the actuations of the pumps and valves, and therefore, the length of every operational cycle in the reactor (Figure 1).

| Operating Phase | Time, min |

|---|---|

| Filling | 5 |

| Reaction | 348 - 320 |

| Settling | 30 - 2 |

| Idle | 5 |

| Total running cycle | 360 |

Details of Phase Duration and Operating Conditions of SBR

The SBR was inoculated by adding 1000 mL of activated sludge (3000 mg/L suspended solids) derived from the aeration basin of a municipal wastewater treatment plant and were fed with synthetic wastewater, which consisted of MEG as the sole source of carbon and energy, and other necessary nutrients. The COD: NH3-N: PO4-P was kept at about 100/5/1. Nutrient composition used was as follows (mg/L): K2HPO4, 58; KH2PO4, 25; NH4Cl 191; NaHCO3, 200; MgSO4.7H2O, 75; and CaCl2.2H2O, 50. Indeed, 1 mL/L of trace elements solution, according to Rafiee et al., (9) was added. It is worth nothing here that the synthetic wastewater was first prepared by glucose and sodium acetate. On day 21 the synthetic mixture of glucose and sodium acetate was replaced stepwise with a fraction of MEG, maintaining the soluble chemical oxygen demand (COD) concentration nearly constant (1,000 ± 10 mg/L). After day 35, it was fed exclusively with MEG wastewater. Sludge retention time (SRT) was set at ≈ 10 days.

The strategy of operation from day 50 on, during which steady-state conditions were established in the reactor, was to gradually reduce the sludge settling time from 30 to 2 minutes, consecutively. The airflow rate concomitantly increased from 2 L/min to 4 L/min in order to cultivate aerobic granules. Special attention was also paid to increase the exchange ratio. The morphological structure of biomass changed notably thereafter, and aerobic granules developed in the reactor.

3.2. Analytical Methods

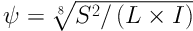

Total suspended solids (TSS), volatile suspended solids (VSS), sludge volume index (SVI), relative hydrophobicity, and F/M ratio were determined according to standard methods (13). Granular biomass was observed regularly by using an optical microscope (Olympus SZX9), a Loop (M6C-10, Japan), and SEM (FEI Company, Philips XL30, Netherlands) in this work. Microscope and Loop images as well as SEM micrographs of aerobic granules were photographed. Mean diameter (Davg) and the sphericity of granules were considered as the important features of developed aggregates. The sphericity was determined as follows:

Where L, I, and S represent long, mean and small diameters of granules, respectively.

4. Results

4.1. Seed Acclimation

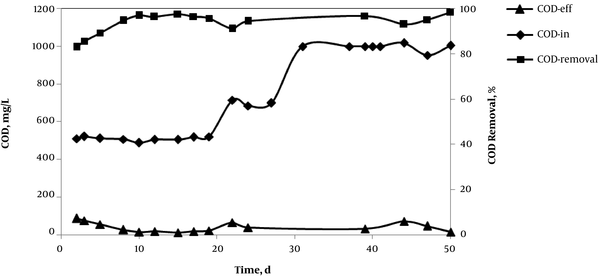

SBR performance during the initial adaptation phase, with glucose and sodium acetate and subsequently MEG, is presented in Figure 2. The reactor was initially operated by 500 mg COD/L, which subsequently increased to 700 mg/L after 3 weeks of operation. After some days, the COD concentration gradually increased up to about 1000 (± 10) mg/L.

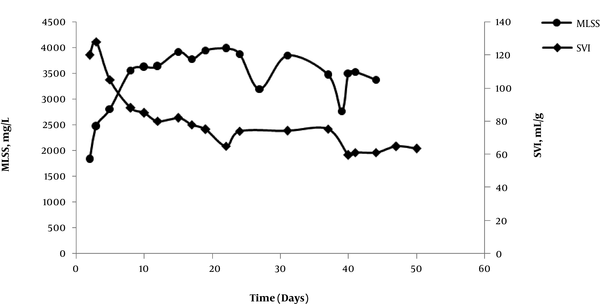

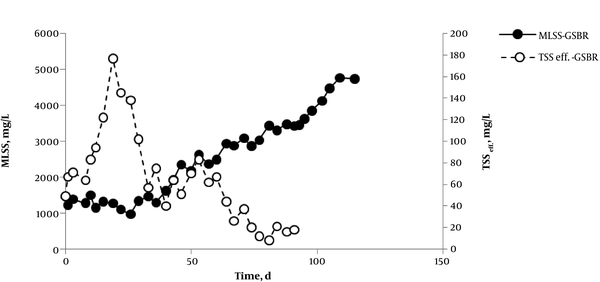

The variations in MLSS and SVI during this initial phase are demonstrated in Figure 3. In the presence of glucose and sodium acetate, MLSS concentration enhanced progressively and it reached equilibrium at 3500 mg/L. Sludge settling ability (SVI) was also altered in this initial phase and reached to an almost constant value of 65 mL/g.

4.2. Development of Aerobic Granules

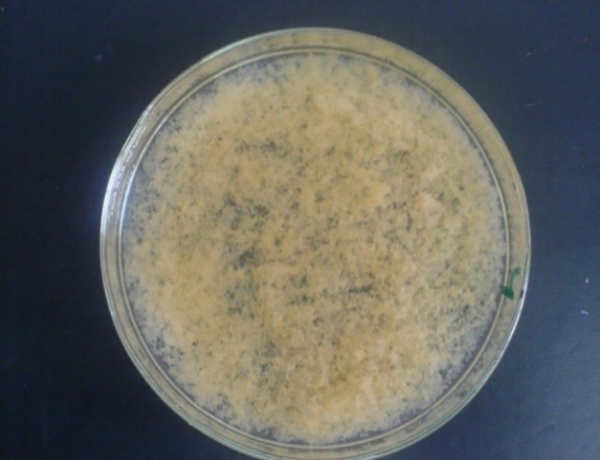

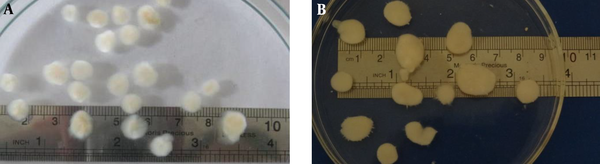

Morphological analysis of the activated sludge cultures used as initial inocula revealed the dominance of fluffy and loose flocculent sludge, with a mean size of approximately 90 µm and a dark brown color (Figure 4). The mean SVI8min and SVI30min of the seed sludge were 173 and 133 mL/g, respectively. The formation of aerobic granules was initiated with gradual alteration in operating conditions and taking into account an array of parameters including feeding strategy, settling time, aeration rate, and exchange ratio.

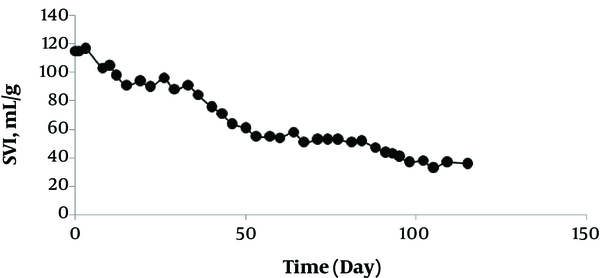

Figure 5 illustrates the morphological transformation of inoculated sludge from day 50 to 115th day of reactor operation. After about three weeks, the fluffy filamentous growth observed during the initial periods disappeared and both SVI8min and SVI30min decreased to 58 mL/g within 75 d after SBR start-up, indicating the transformation of flocculent sludge into initial microbial aggregates; however, granular sludge were not seen yet (Figure 5A). These initial loose aggregates had an irregular round shape with filament growth observed on the edges, and a size of 3 to 8 mm. Dense, round stable granules, with integrated structure dominated in the SBR by the 115th day (16 weeks after operation) (Figure 5B). The mean diameter of mature aerobic granules on the 115th day was 8.2 mm and the largest diameter of these granules was 11.6 mm. Table 2 lists the characteristics of mature granules after the steady state operation established in the SBR.

| Parameter | Unit | Value |

|---|---|---|

| SVI | mL/g | 58.0 |

| Davg | mm | 8.21 ± 2.66 |

| Colour | - | yellow |

| Circularity | - | 0.90 ± 0.04 |

Characteristics of Mature Granules After Steady State Operation

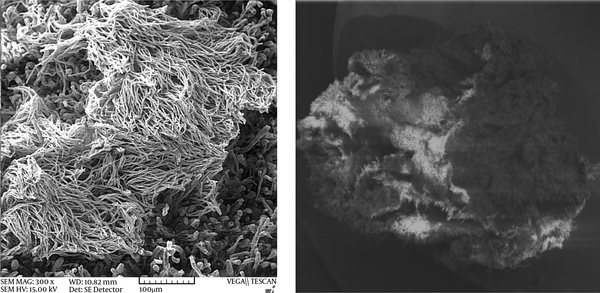

Aerobic granules were photographed by using a SEM. Figure 6 presents two SEM micrographs. As it can be observed, aerobic granules are small balls of biomass structured by of a wide variety of microorganisms.

5. Discussion

5.1. Seed Acclimation

After a few cycles during seed acclimation, the colour of mixed liquor in SBR turned towards yellowish-white, indicating a normal start up, high DO, or a very high BOD loading with a matching high F/M ratio (i.e., low SRT). Substrate removal in this stage implies the biomass capability in consuming MEG as the main sources of carbon and energy.

The variations in MLSS and SVI during this initial phase as presented in Figure 3 could be attributed to the reactor configuration. It was never reported that reactor configuration has a dominant effect on the flow patterns of liquid and microbial aggregates in the reactor (14). In a column-type SBR, air, and thus, liquid flow is subject to an up-flow pattern. This pattern results in a relatively homogenous circular flow and localized vortex along the reactor height; therefore, flocculent sludge is continually subjected to circular hydraulic attrition (14). According to the thermodynamics, the circular flow could force loose flocculent sludge to be shaped as regular microbial aggregates, which confers them an enhanced settling ability.

5.2. Development of Aerobic Granules

The size of aerobic granules developed in the present study using MEG is much larger for the similar time frame as compared to the earlier reports on synthetic or real wastewater (15-17). The literature already includes several reports of selective pressures effecting aerobic granulation. However, few studies have specifically dealt with the size and structure of these microbial aggregates. Such an observation may be explained by applied hydrodynamic shear force, substrate composition, and organic loading rate as well as feeding strategy.

Aerobic granules can grow on a broad range of substrates (18, 19). There is good evidence that the physical features of aerobic granular sludge rely upon the organic loading rate, Lorg. It seems possible that well-compacted aerobic granules in this study is due to the applied low volumetric organic loading rate (2 Kg COD/m3.d). Although firm evidence is lacking, however, the exploited loading rate in this work was lower than the reported range (2.5 - 15.0 kg COD/m3.d) (20). This was in line with a generally assumed pattern, where an increase in Lorg is associated with an increase in microbial growth rate, which in turn leads to a decreased structural strength of aerobic granules (20, 21). In addition, the high employed feast-famine ratio, as well as anoxic feeding is believed to have played its role in the development of compact and dense aerobic granules in this work.

In general, the formation of granular sludge is associated with the production of different structures of EPS that seem to act as a ‘glue’ stabilizing the granules (Figure 6), providing a niche in which species of different microbial taxa can optimally develop in symbiosis. The role played by EPS in the granulation might be to posse the ability to increase the hydrophobicity (Table 2) and alter the surface charges on the microbial population (22, 23). As a result, it was possible to draw a meaningful conclusion relating to the impact of hydrophobicity and microorganisms’ surface charge on the microbial cell adhesion and granulation. Therefore, though hydrodynamic shear force has not been reported as a primary inducer of granulation in SBR, the development of more compact, round, and stronger granules in the present work could be ascribed by the applied high shear in terms of superficial up-flow air velocity.

There observed a slightly decrease in time duration needed for the appearance of mature aerobic granules in the present study (65 days) compared to that of previous studies carried out with simulated synthetic or real industrial and domestic wastewaters (16, 17), which could be attributed to the H/D and exchange ratios of the SBR. It was ever reported that reactor configuration in terms of H/D ratio plays a key role on aerobic granulation through an impact on the flow patterns of liquid and microbial aggregates in the reactor (14). This might be resulted from the effect of H/D ratio on the hydro and thermodynamic behavior of the reactor creating a more effective hydraulic attrition for microbial aggregates. It is seen from the comparison of the reactor’s H/D ratio in the present study (8.5) and the literature findings that reactor configuration causes much change in the granular biomass structure.

A significant contribution of the exchange ratio towards aerobic granulation has also been discussed on many literature works (18, 24). Thus, in order to promote the formation of aerobic granules, the exchange ratio was set at 25% during the first days of operation and gradually increased to 75% within a period of 50 days. The exchange ratio was kept constant from day 100 on. The fraction of granular sludge in the total biomass was deeply affected by the exchange ratio, e.g. the SBR was dominated by aerobic granules only at the higher exchange ratios of 60% and 75%; and a mixture of aerobic granules and fluffy particles instead of pure aerobic granules developed at the smaller exchange ratios, which is in good agreement with decrease in the SVI5min value as observed in Figure 7. The decrease in SVI might be resulted from the loss of light particles from the reactor due to discharge of a high volume of treated effluent where the fast settling and denser biomass remains in the SBR. These denser and fast settling granular aggregates noticeably declined the SVI value and concurrently enhanced the settling ability of biomass.

Similar to the experiments with hydrodynamic shear force and exchange ratio, the biomass structure in the SBR was mainly affected by the given settling time (Figure 8). The short settling time coupled with high exchange ratio adapted in this work led to select the fast settling denser biomass caused by the wash out of poorly settling fluffy flocs. The denser particles remained in the reactor eventually transformed into aerobic granules. In support of the present study, settling time has been extensively reported as a decisive factor in the formation of aerobic granules in SBR (18, 19, 25).

5.3. Conclusion

Aerobic granules with dense and strong microbial structure as well as excellent settling ability were developed with synthetic wastewater containing MEG as the sole source of carbon and energy. Cultivated granules showed a long biomass residence time and high and stable rate of metabolism. This combination of findings provides some support for the conceptual premise that aerobic granulation enjoy an advantage of good separation of biomass from treated effluent and consequently shorter settling time.