1. Background

In an industrial process, every activity has potential to error. This error may be a system error or human error. System error is caused by system control which if corrected that will not occur again, but human error is such that even if people are taught the correct way of doing work and understand it, they cannot be prevented due to the complex functioning of the system (1).

Today, in many industries, sensitive systems with advanced technologies are used. Since these systems interact with humans, the potential for risks due to human errors in these processes is high. Human error includes the deviation of human performance from specified rules and duties, which exceeds the acceptable limit of the system and has an adverse effect on the efficiency of system (2, 3).

In another definition, human errors are a set of actions that violate predetermined norms, limits, standards and have a negative effect on system performance (4).

The study of various accidents shows that despite advances and automation in industries and the reduction of the human role in the work environment, human error can also cause fatal and financial accidents. On the one hand, human duties in the work environment are associated with an increase in psychological and intellectual load and the complexity of work, which increases the probability of errors, and on the other hand, with the increase in the burden of responsibility, the consequences of human errors become more expensive (5, 6).

Based on the studies that conducted on the causes of industrial accidents, more than 90% of nuclear accidents, more than 80% of chemical industry accidents and more than 70% of aviation accidents have been announced to human error (7).

Another incident where human footprints are seen as a cause is the incident in Bhopal, India, which occurred in 1984 and caused the death of more than 3,000 people and genetic problems for 300,000 people (8).

Many other catastrophic events in history, including the Hillsborough football stadium disaster, the Paddington train accident and the Southall train accident, and the Chernobyl and Three MileIsland disasters and the Chalenger space shuttle occurred as a result of human errors (9).

The studies conducted in this field indicate that the occurrence of human errors is the result of a combination of factors such as inappropriate safety instructions, insufficient supervision, fatigue, work pressure, lack of proper maintenance and repair complexity of work methods, and environmental conditions, personal factors and managerial and organizational factors occur (10).

In general, there are several methods for identifying human errors, including: The human error detection and reduction method (HEART), the cognitive error analysis and human reliability (CREAM), the human event analysis technique (ATHEANA) and the systematic approach to error prediction and reduction (SHERPA) have been introduced. Each of the mentioned methods has its own strengths and weaknesses. Choosing the right technique is the first step in human error risk assessment studies (11).

2. Objectives

The present study was carried out with the aim of prediction and assessment of human errors in a control room of the steam power plant by SHERPA method.

3. Methods

The current study is a descriptive cross-sectional that was conducted in control room of a steam power plant in 2021. The number of control room workers in each shift were 15 that worked in 8 hour rotating shifts. After interviewing with process experts and control room operators that included (thermal board, turbine, boiler and cycle and Turbine critical tasks) that were prone to human error were identified. In first phase of this research, they were analyzed by reviewing the job description and interviewing the supervisor of the control room as well as the shift workers of the control room, reviewing documents and documents using the hierarchical task analysis (HTA) method. After carrying out the hierarchical tasks analysis and identifying the subtasks, it was time to complete implement the SHERPA method which include 8 steps. This human error analysis method consists of a program calculated from the normal flow of questions and answers that analyze similar errors at each stage of job tasks (12).

In order to complete implement of this technique, there are 8 steps that are given below:

Step 1. HTA: In this method, tasks should be broken into subtasks and continue until there are no more subtasks of those tasks.

Step 2. Task classification: After analyzing the task in order the lowest level, the tasks are divided into 5 categories. Each stage of the work from the lowest level of analysis is considered for classification as follows:

(1) Action error: Like opening a door

(2) Retrieval error: Receiving information through regulations, instructions, circulars, displays, etc.

(3) Checking (reviewing) guidance and managing review process

(4) Selection error: Choosing another solution according to the command of a higher official

Communication error: Interview with other departments or groups

Step 3. Identifying human error: The classification of task steps guides the analyst to investigate the activity error using downstream error classification. In this step, human error tables were used in SHERPA method (13).

Step 4. Consequence analysis: Examining the results of each error on the system is a vital step that it will have practical results for critical errors. It is necessary for the analyst to provide a complete description of the results along with identifying the error. The evaluation criteria of the consequence analysis are the risk levels obtained from the identification and evaluation of errors.

Step 5. Recovery analysis: In this stage, the analyst must determine the potential recovery of the identified errors.

Step 6. Error probability analysis: In this step, the probability of an error is determined. In this step, the errors were classified into low, medium and high groups.

Step 7. Critical analysis: A critical error is considered if that leads to a severe and unacceptable event and basically its results can cause damage to the organization, industry, product and employees.

Step 8. Analysis of control and corrective actions: In this step, errors reduction strategies are presented. The studies of the SHERPA method shows that this method has acceptable validity for identifying human errors (14). After collecting data, in the column related to the level of error risk use qualitative evaluation method which classificate human errors according to their severity into four categories: Catastrophic, critical, borderline, and minor. The severity of damages mention by frequent, probable, occasional, very little and unlikely. The risk level is the combination of risk probability and severity for each of errors were quantitatively estimated (15).

One of the valid identifications and evaluation methods is SHERPA method which detects errors based on the principles of human psychology resulting from task analysis. In 1986, Emberi designed and introduced this method and it was completed in 1994. Systematic approach to error prediction and reduction is accurate in providing practical control solutions according to the type of error identified (16).

As the most important infrastructure industry, the electricity industry plays a significant role in the industrial infrastructure, so it is necessary to produce, transmit and distribute electric energy with at least amount of disturbance in quality and quantity. The human factor is one of the factors affecting the accidents that lead to network interruptions and interruptions in the electricity industry. Forecasting, identifying and controlling the factors that affect human performance and improving his reliability in the electricity production, transmission and distribution system can play a significant role in the stability of the network and reducing their direct and indirect damages. The investigation of 273 accidents in the studied electricity company over the past 3 years shows that 62.5% of the total accidents and also 73.8% of work accidents caused in the contracting department of the same company were caused by human errors (17, 18).

Examining the results of incident analysis and soliciting opinions from managers and experts showed that the role of the post operator as the most key human force in the process of personnel transfer is very important. Various methods are used to predict and identify human errors (17).

The purpose of this study was evaluated and identify the human errors in control room of a steam power plant in order to determine the level of risk and the consequences of such sometimes irreparable errors. Finally, by performing this risk assessment technique, control solutions we can reduce human errors and level of risks in future programs (19).

After collecting data, in the column related to the level of error risk use qualitative evaluation method which classificate human errors according to their severity into 4 categories: catastrophic, critical, borderline, and minor. The severity of damages mentions by frequent, probable, Occasional, very little and unlikely. The risk level is the combination of risk probability and severity for each of errors were quantitatively estimated (15). SHERPA method has been done in many industries but no study has been done in control room of power plants, so we decided to do it in order to prevent possible human errors in future. The purpose of this study was evaluated and identify the human errors in control room of a steam power plant in order to determine the level of risk and the consequences of such sometimes irreparable errors.

4. Results

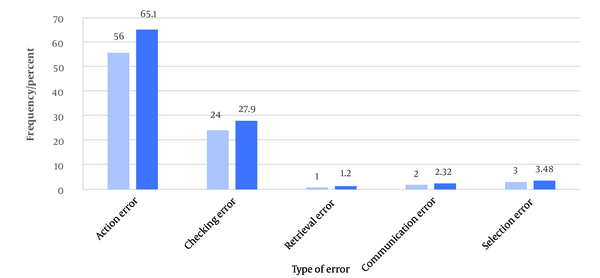

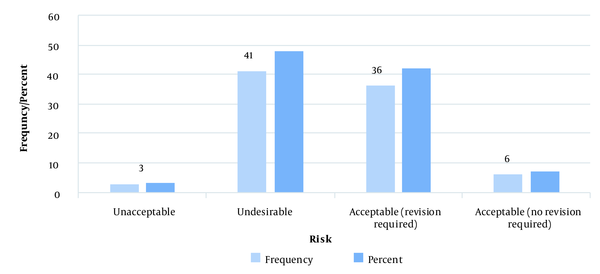

In this study, HTA of each control room operators was conducted. Then the human errors of the subtasks were identified according to the method for each tasks. The duties of 5 control room operators, which include thermal board, boiler, cycle and turbine, turbine and electric operators, respectively thermal board operator 6 main tasks, boiler 3, cycle and turbine 3, turbine 3 and electric 3 main tasks were examined. The information obtained from the SHERPA worksheets showed that out of a total of 86 errors identified in Table 1, 56 (65.1%) related to action error, 24 (27.9%) related to checking error, 1 (1.2%) related to recovery error, 2 (2.32%) related to communication error and 3 (48.3%) related to selection error (Figure 1). By conducting risk assessment, the highest frequency related to the level of undesirable risk (41) and acceptable with the need for revision (36) and the lowest frequency related to the level of unacceptable risk (3) and acceptable without the need for revision were determined (Figure 2). Also, 35 errors were reported at the critical level and 51 errors at the non-critical level (Table 2).

| Error Type/Error Code | Error Description | Error, No. (%) |

|---|---|---|

| Action error | ||

| A1 | The operation is done too soon or too late | 3 (3.48) |

| A2 | The desired action is performed without time | 4 (4.65) |

| A3 | The desired action is performed in the wrong direction | 6 (7) |

| A4 | The operation is performed less or more than necessary | 2 (2.32) |

| A5 | The change is done | 10 (11.62) |

| A6 | The correct action is performed on the wrong option | 3 (3.43) |

| A7 | The wrong action is performed on the correct option | - |

| A8 | Forget about doing the desired action | 16 (18.6) |

| A9 | The operation is performed incompletely | 12 (13.95) |

| A10 | The wrong action is performed on the wrong option | - |

| Checking error | ||

| C1 | The review is forgotten | 5 (6) |

| C2 | The review is incomplete | 8 (9.9) |

| C3 | The correct check is done on the wrong option | - |

| C4 | Error checking is done on the correct option | - |

| C5 | The review is done at the wrong time | 10 (12) |

| C6 | The wrong check is done on the wrong option | - |

| Retrieval error | ||

| R1 | Required information is not available | - |

| R2 | The information is provided incorrectly | 1 (1.2) |

| R3 | Data recovery is incomplete | - |

| Communication error | ||

| I1 | No information is exchanged | 1 (1.2) |

| I2 | Wrong information is exchanged | 1 (1.2) |

| I3 | Information exchange is incomplete | - |

| Selection error | ||

| S1 | The selection is removed | - |

| S2 | The wrong choice is made | 3 (3.48) |

| Total errors | 86 (100) |

Type, Frequency and Percentage of Identified Risks in Control Room of a Steam Power Plant

| Error Criticality | Frequency (%) |

|---|---|

| Critical | 35 (40.6) |

| Non-critical | 51 (59.4) |

Frequency and Percentage of Criticality of Human Errors

5. Discussion

Human errors are one of the most important factors that lead to accidents in various industries. In order to prevent and limit consequences that caused by human error, it is important to predict, identify and find their causes (12). The purpose of this study was to identify and evaluate human errors in control room of a steam power plant using a systematic approach to predict and reduce human errors. In the present study, the most identified error was related to action error with frequency of 56. In the study by Habibi et al. which was carried out by SHERPA method in the control room operators of Isfahan oil refinery, the amount of action errors identified was high (20). In the study of Halvani et al., which aimed to investigate human errors in control room operators of Parsian gas company, using the SHERPA technique, the most identified errors were related to action errors (12). The results of our study are consistent with previous studies. In order to reduce the amount of action errors in industries, it is recommended to use checklists and instructions according to the work (20). Another solution that can be mentioned is the use of a simulator system. The identified errors in this method are included software and by applying it during the training, the trainee's ability to control the created conditions is evaluated, functional skills of people also increase (12).

In the current study, the most common type of action errors was forgetfulness in doing work, which is consistent with the study of Habibi et al. (20). Since most of the identified errors were forgetting to do the work (deletion of items from the work instructions) (Table 1), it seems that creating a suitable cultural platform for doing the work according to the instructions is one of the ways to eliminate or reduce this type of errors (14, 21). In this regard, Jahangiri believes that in performing a step of the work, if there is no means to remember, the probability of the operator's forgetting error is 1.0, and if a checklist is used to perform those work steps, or the work steps in the instruction format is brought, it will be reduced to 0.003 (22). In a study that was conducted by ZarraNezhad et al. with the aim of identifying human errors in control room operators using the HEIST technique, the results showed that work instructions caused 40% of the total identification errors in that study, the lack of written instructions based on after selecting the target, the solution that user chooses to deal with emergency situations and restore the system to normal state, causes confusion and increases the amount of human errors (23). Human error in the duties of control room operators is always sensitive and important because the necessary coverage may not be done in time (20). In a study was conducted by Yang et al. about cause of human error in a control room of nuclear power plant in 2007, it was shown that the number of operators, environmental factors and psychological characteristics can be the cause of human error and subsequent accidents (24).

Performing the operation incompletely was another functional error with high frequency in our study. In this case, it can be effective to provide a codified implementation method for recording reports and training workers about its importance. In the 2005 oil refinery explosion at BP in Texas, one of the root causes of the accident was the incomprehensible and short recording of the additional load in the tower by the operator of the previous shift, which led to irreparable loss of life and money (25). Transferring correct information is very effective in reducing the possibility of human error. Therefore, information exchange systems play an important role in this matter (26). The results of the present study showed that 51% of the errors were unacceptable and undesirable. Using SHERPA method, Jafari et al. (18) conducted a research in the field of identifying and predicting human error in the control room of 400 KV substations. It showed that more than half (54.2) of the identified errors have unacceptable risk. In the study of Halvani et al. which was conducted about human error detection and prediction in the control room of Parsian gas company, approximately 93% of the errors were unacceptable and undesirable level, which is consistent with the results of this study (12). A combination effects were created by personal factors, managerial and organizational factors, job complexity, environmental conditions, design of equipment and devices, supervision, presence or absence of work instructions, etc. occur so that only one action cannot be considered as the main cause of human errors. In the control rooms, the lack of clarity in the instructions and description of duties and how the operator communicates with the dispatching center can also be the source of human errors.

5.1. Limitations

Some of limitations of this study included: Lack of human error records and little studies in this field.

5.2. Conclusions

Among the control methods proposed in this research are creating software changes in the control system, training employees, monitoring the performance of employees, compiling work instructions, training employees through a simulator system, optimizing communication devices, compiling a checklist, installing hardware equipment. In the system, there is the implementation of work permit system, equipment calibration, etc.