1. Background

Pomelo is a key fruit crop in the Mekong Delta, particularly in provinces such as Vinh Long, Tien Giang, and Ben Tre, playing a vital role in agriculture and local economic development. It generates significant economic value and contributes substantially to the region's agricultural sector. In Vinh Long, Pomelo cultivation is concentrated in the districts of Binh Minh, Tra On, Long Ho, and Mang Thit, providing a major source of income for local farmers (1). In addition to its nutritional value, Pomelo peel serves as a valuable raw material due to its high content of beneficial compounds, including essential oil, naringin, and pectin. Notably, limonene is the primary constituent of Pomelo peel essential oil, exhibiting antibacterial, antioxidant, and hair growth-stimulating properties, along with a calming effect. Due to these bioactive properties, limonene is widely applied in the pharmaceutical, cosmetic, and food industries (2-6).

However, the quality of Pomelo peel essential oil is influenced by various factors, including Pomelo variety, environmental conditions, and extraction methods (7-9). Therefore, optimizing the extraction process to achieve high yield while ensuring quality control through appropriate analytical techniques is essential. Among the available analytical methods, gas chromatography-flame ionization detection (GC-FID) is considered a highly effective technique due to its high sensitivity and accuracy, enabling precise quantification of limonene in the essential oil (10).

Although various studies have investigated Pomelo peel essential oil (1, 11-13), none have compared the extraction efficiency among different Pomelo varieties cultivated in Vinh Long, Vietnam. Furthermore, no official quality standards for Pomelo peel essential oil have been established in the Vietnamese Pharmacopoeia, the United States Pharmacopeia, or the European Pharmacopoeia. Therefore, this study provides a scientific foundation for the development and application of value-added products derived from this natural resource.

2. Objectives

This study investigates the factors influencing extraction efficiency, validates the analytical method for limonene quantification, and establishes quality standards for Pomelo peel essential oil using GC-FID.

3. Methods

3.1. Materials

Pomelos were harvested from Mang Thit District, Vinh Long Province, washed, and separated to collect the peel. The peel was cut into small strips (2 × 5 mm) and either used within 24 hours or stored at 0°C until further analysis. Limonene standard (98.5% purity, batch number 51019) was supplied by Dr. Ehrenstorfer GmbH (Germany).

3.2. Extraction of Essential Oil Using the Hydrodistillation Method

An accurately weighed 100 g of Pomelo peel was subjected to the hydrodistillation method using distilled water as the solvent. The distillation was performed with a Clevenger apparatus connected to a 2000 mL Erlenmeyer flask, heated directly on an electric stove. The extracted Pomelo peel essential oil was subsequently dried with anhydrous sodium sulfate and stored in a dark glass bottle at 2 - 5°C (14, 15).

3.3. Investigation of Factors Influencing Extraction Efficiency

The extraction process of Pomelo peel essential oil was evaluated by analyzing various influencing factors, including the raw material-to-solvent ratio (X1: 1:3, 1:4, 1:5), extraction time (X2: 90 min, 120 min, 150 min), distillation rate (X3: Level 3-low, level 4-medium, level 5-high), material size (X4: 0-unground, 1-ground), and Pomelo variety (X5: CG-Citrus grandis, CM-Citrus maxima). These factors were optimized to maximize essential oil yield (16-18). The extraction yield of Pomelo peel essential oil was determined using the following Equation 1:

Where a: The volume of extracted Pomelo peel essential oil (mL) and b: The mass of Pomelo peel used for extraction (g).

3.4. Validation of Limonene Quantification by Gas Chromatography-Flame Ionization Detection

3.4.1. Preparation of Standards

Accurately weigh approximately 0.01 g of limonene standard into a 5 mL volumetric flask. Dissolve in isopropanol and dilute to volume to obtain a stock standard solution with a concentration of 2000 µg/mL. Precisely pipette 1 mL of the stock standard solution into a 5 mL volumetric flask, dilute to volume with isopropanol, and obtain a working standard solution with a concentration of 400 µg/mL.

3.4.2. Preparation of Samples

Accurately weigh approximately 0.01 g of Pomelo peel essential oil into a 5 mL volumetric flask. Dissolve in isopropanol and dilute to volume to obtain a stock sample solution with a concentration of 2000 µg/mL. Precisely pipette 1 mL of this solution into a 5 mL volumetric flask, dilute to volume with isopropanol, and obtain a final sample solution with a concentration of 400 µg/mL.

3.4.3. Gas Chromatography-Flame Ionization Detection Analysis

The analysis was performed using an Agilent 7890B gas chromatography system equipped with a flame ionization detector. The separation was carried out on an HP-5 capillary column (19091J-413; 30.0 m × 0.32 mm × 0.25 μm). Nitrogen was used as the carrier gas in constant pressure mode at 5.184 psi, with a flow rate of 24 mL/min. The column temperature program was initially set at 60°C, then increased at a rate of 3°C/min until reaching 250°C. Sample injection was performed in split mode (10:1) at 250°C, with a 0.1 μL injection volume. The detection was carried out using FID at a temperature of 280°C, with a hydrogen fuel flow rate of 50 mL/min, an air flow rate of 300 mL/min, and a makeup flow rate of 25 mL/min (19).

3.4.4. Method Validation

Method validation was conducted following ICH and AOAC guidelines, evaluating parameters such as system suitability, selectivity, linearity, precision, and accuracy (20, 21).

3.5. Establishment of Quality Standards for Pomelo Peel Essential Oil Using Gas Chromatography-Flame Ionization Detection

The quality of the extracted Pomelo peel essential oil was assessed according to the standards outlined in the International Organization for Standardization (ISO) 3053:2004, which included parameters such as physical properties, density, refractive index, specific optical rotation, residue after evaporation, and limonene content (22).

3.5.1. Physical Properties

The essential oil is a colorless, volatile liquid with the characteristic aroma of Pomelo.

3.5.2. Density (Pycnometer Method)

The density was determined as the ratio of the mass of Pomelo peel essential oil to the mass of distilled water at 20°C (23).

3.5.3. Refractive Index

The refractive index was determined using a refractometer at 20°C ± 0.5°C, employing light with a wavelength corresponding to the sodium D-line (589.3 nm). Prior to measurement, the refractometer was calibrated using distilled water, which has a refractive index of 1.3330 at 20°C (23).

3.5.4. Specific Optical Rotation

The specific optical rotation was determined using a polarimeter at 20°C ± 0.5°C, utilizing light with a wavelength corresponding to the sodium D-line. Prior to measurement, the polarimeter was calibrated by setting the zero point with an empty measurement tube for liquid samples. Following calibration, the sample was analyzed to determine its specific optical rotation

3.5.5. Residue After Evaporation

The evaporation dish was preconditioned by heating in a water bath for 1 hour, drying, cooling, and placing in a desiccator before weighing its tare mass (m4). Precisely 5 g of essential oil was weighed into the prepared dish, which was then placed on the water bath at a position with a 70 mm diameter opening. Throughout the evaporation process, the water level in the bath was maintained approximately 50 mm below the surface. The water was boiled under atmospheric pressure, and the essential oil was evaporated to dryness. Finally, the dish was cooled in a desiccator and reweighed to determine the residual mass (m5) (23).

The residue after evaporation of Pomelo essential oil was calculated using the following Equation 2:

3.5.6. Limonene Content

The limonene content in Pomelo peel essential oil was determined using GC-FID, following the validated procedure described above.

4. Results

4.1. Investigation of Factors Influencing Extraction Efficiency

The results of the extraction yield of Pomelo peel essential oil are presented in Table 1. Table 1 outlines the extraction process parameters, which include a raw material-to-solvent ratio of 1:4, an extraction time of 120 minutes, a distillation rate at level 5-high, ground raw material size, and the use of the C. maxima variety. These optimized conditions resulted in an extraction yield of 2.6%.

| Run | X1 | X2 (min) | X3 | X4 | X5 | Y% (v/w) |

|---|---|---|---|---|---|---|

| F1 | 1:3 | 120 | 4 | 0 | CG | 0.67 |

| F2 | 1:4 | 120 | 4 | 0 | CG | 0.83 |

| F3 | 1:5 | 120 | 4 | 0 | CG | 0.70 |

| F4 | X1 | 90 | 4 | 0 | CG | 0.65 |

| F5 | X1 | 120 | 4 | 0 | CG | 0.85 |

| F6 | X1 | 150 | 4 | 0 | CG | 0.70 |

| F7 | X1 | X2 | 4 | 0 | CG | 0.83 |

| F8 | X1 | X2 | 3 | 0 | CG | 0.60 |

| F9 | X1 | X2 | 5 | 0 | CG | 0.85 |

| F10 | X1 | X2 | X3 | 1 | CG | 2.00 |

| F11 | X1 | X2 | X3 | 1 | CM | 2.60 |

Abbreviations: X1, the raw material-to-solvent ratio; X2, the extraction time; X3, the distillation rate; X4, the material size (0-unground, 1-ground); X5, the pomelo variety; CG, Citrus grandis; CM, C. maxima.

4.2. Validation of Limonene Quantification by Gas Chromatography-Flame Ionization Detection

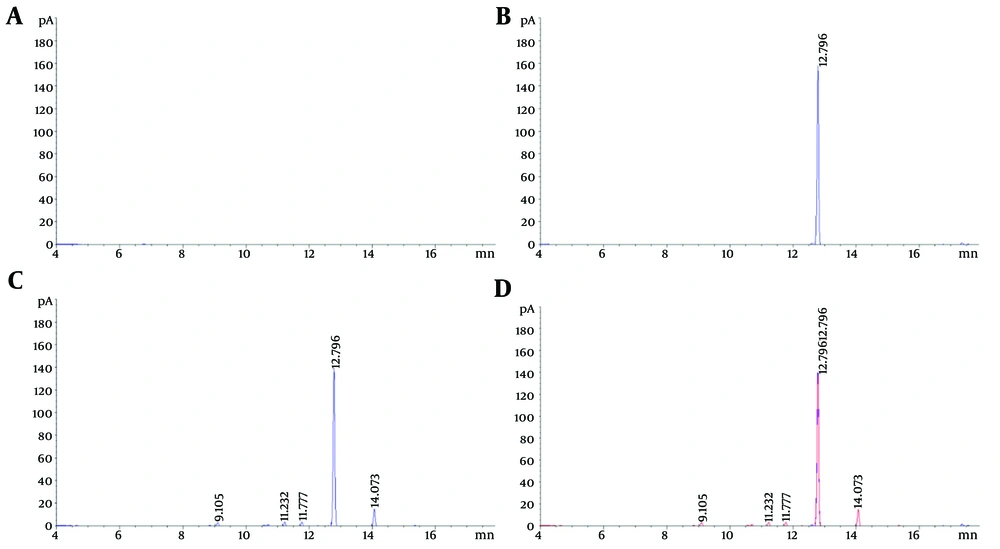

The system suitability results are presented in Table 2 (Appendix 1 in Supplementary File). The specificity assessment results showed that the chromatogram of the blank sample exhibited no peak at the retention time corresponding to the standard sample. In contrast, the chromatogram of the test sample displayed a peak with a retention time identical to that of the standard sample. Additionally, the peak of the active compound in the test sample chromatogram was completely separated, ensuring the required resolution (Figure 1).

| Variables | tR (min) | S (pA*s) | As | Rs | N |

|---|---|---|---|---|---|

| Standard | |||||

| Mean | 12.796 | 601.583 | 1.266 | - | 255406.500 |

| RSD (%) | 0.004 | 0.903 | 0.859 | - | 0.958 |

| Sample | |||||

| Mean | 12.796 | 535.167 | 1.174 | 10.162 | 247239.667 |

| RSD (%) | 0.004 | 0.898 | 0.530 | 0.115 | 0.801 |

Abbreviations: tR, retention time; S, peak area; As, asymmetry factor; Rs, resolution; N, number of theoretical plates.

The values of validation parameters are summarized in Table 3 (Appendices 2 - 8 in Supplementary File). Validation results confirmed that the GC-FID method met system suitability requirements, selectivity, high precision (RSD < 2%), and accuracy (90.0 - 108.0%).

| Validation Characteristics | Limonene |

|---|---|

| Linearity range (µg/mL) | 98.5 - 985 |

| Regression equation | y = 1.642x - 44.449 |

| Regression coefficient (R2) | 0.9995 |

| Repeatability (n = 6) | RSD = 0.498% |

| Accuracy (n = 9, P < 0.05) | |

| Recovery (%) | 101.870 - 103.235 |

| RSD (%) | 0.531 |

| LOD (µg/mL) | 24.424 |

| LOQ (µg/mL) | 74.012 |

Abbreviations: LOD, limit of detection; LOQ, limit of quantification.

4.3. Establishment of Quality Standards for Pomelo Peel Essential Oil Using Gas Chromatography-Flame Ionization Detection

The quality of Pomelo peel essential oil from Vinh Long province was assessed based on the specification limits outlined in ISO 3053:2004. This assessment included parameters such as physical properties, density, refractive index, specific optical rotation, residue after evaporation, and limonene content, as presented in Table 4 (Appendix 7 in Supplementary File). These parameters ensure that the essential oil meets the established quality standards, providing a reliable basis for its application in various industries.

| No. | Parameters | Specification | Results |

|---|---|---|---|

| 1 | Physical properties | A colorless, volatile liquid with the characteristic aroma of Pomelo | Complies |

| 2 | Density | At 20ºC: 0.852 - 0.860 | Complies (0.854 ± 0.001) |

| 3 | Refractive Index | At 20ºC: 1.474 - 1.479 | Complies (1.475 ± 0.001) |

| 4 | Specific optical rotation | At 20ºC: +91º - +96º | Complies (93.360) |

| 5 | Residue after evaporation | Not more than 10% | Complies (1.623 ± 0.003) |

| 6 | Limonene content | Not less than 80% | Complies (CG: 84.178 ± 0.771%; CM 97.960 ± 0.013) |

Abbreviations: CG, Citrus grandis; CM, C. maxima.

5. Discussion

Various methods are available for essential oil extraction, including hydrodistillation, cold pressing, ultrasound-assisted extraction, and microwave-assisted extraction (15, 24-26). Each method has distinct advantages and disadvantages that affect the extraction yield and chemical composition of the essential oil. In this study, the hydrodistillation method was chosen for its widespread application and effectiveness in obtaining pure essential oil (27). While effective in preserving key constituents such as limonene, hydrodistillation may lead to the loss of certain volatile compounds due to the high extraction temperature. Notably, a study by Bai et al. reported that the limonene content from Mentha longifolia essential oil extracted by hydrodistillation was higher than that obtained using other extraction techniques (4).

However, it is essential to evaluate the influencing factors to select an optimal extraction process. The raw material-to-solvent ratio directly influences extraction yield by modulating steam requirements (28). The results indicated that a ratio of 1:4 resulted in an extraction yield of 0.83%, while increasing the ratio beyond this point led to a reduction in yield. Extraction time also plays a crucial role in essential oil recovery. If the extraction time is too short, the process may be incomplete, whereas excessive extraction time could lead to the degradation of certain compounds due to prolonged exposure to high temperatures. Table 1 showed that an extraction time of 120 minutes was optimal.

Additionally, an excessively high distillation rate may cause the loss of volatile compounds (such as limonene and myrcene, which have low boiling points), while a low rate may prevent the complete release of essential oil from the raw material, thereby reducing extraction efficiency. In this study, the maximum extraction yield for C. grandis was 2.00% (F10), which is slightly higher than the 1.9% reported by Phat et al. (1). Furthermore, the yield for C. maxima reached 2.60% (F11), considerably exceeding the 1.09% documented by Das et al. (11).

Previous studies focused on qualitative analysis and comprehensive identification of essential oil components using the GC-MS method (10, 19). In this study, the GC-FID method was employed for limonene quantification because it offers high accuracy, excellent repeatability, and rapid analysis time.

5.1. Conclusions

Overall, this study optimized the extraction process and established quality standards for Pomelo peel essential oil from Vinh Long, providing a solid foundation for its broader application in the pharmaceutical, cosmetic, and related industries.