1. Background

The release of oil spills, whether unintentionally or advertently, causes water and soil pollution (1). Water contamination with hydrocarbons endangers the health of aquatics as hydrocarbons easily accumulate in their tissues, thereby leading to death or mutations (2). Several techniques have been used to remediate the environments that are polluted with oils; such examples are mechanical methods (e.g., floatation) (3, 4), evaporation (5), adsorption (6), and chemical treatment (7). However, these methods are costly and may result in the deficient decomposition of the hydrocarbons with a complex structure (8).

Bioremediation is the process of using microorganisms to remove or convert pollutants into non-hazardous products. It is an evolving method with the advantages of cost- effectiveness and noninvasiveness to the species that are adapted to the environment (9). Many researchers have investigated the use of various natural microorganism populations to partially destroy or remove hydrocarbons (10, 11). Among the more soluble and toxic compounds found in polluted water, aromatic compounds (e.g., benzene, toluene, ethylbenzene, xylene isomers, and phenols) are of great concern as the removal of these compounds is extremely strenuous. Furthermore, they are highly toxic, which hinders the direct use of biological treatments (12, 13). To overcome this limitation, Oil Spill Eater II (OSE II) has been introduced and applied extensively for the reduction of clean-up costs and permanent elimination of hazardous wastes without the need for secondary clean-up (14).

OSE II is a biological enzyme that converts wastes into a natural food source for the native bacteria of the environment, with the end result of CO2 and water. In fact, OSE II usage is preferred over other chemicals owing to its independency of any foreign bacteria or indigenous organisms. OSE II contains biosurfactants and nutrients that attract the indigenous bacteria found in the environment, which rapidly colonize in numbers, thereby accelerating spill remediation (15).

2. Objectives

Due to the high concentration of oil contaminants around oil rigs, their spread in the affected water environment is highly likely. The present study aimed to assess the effects of OSE II on the reduction of total petroleum hydrocarbons (TPHs) provided by various oil companies (Bahregan, Lavan, Qeshm, and Siri crude oil) in the samples collected from the seawater in Bushehr, as an example of the aquatic environment hosting hydrocarbons, during summer 2019.

3. Methods

Initially, a specific amount of crude oil, which was collected from different regions, was mixed with seawater (obtained from Bushehr region) in accordance with the instructions of the manufacturer (15). In the next step, a combination of seawater and hydrocarbon was mixed with a specific ratio of OSE II in compliance with the relevant instructions (15), and the resulting mixture was oxygenated using an aerator with the air flow of 1.5 l/min.

Overall, the current research was conducted in three stages (1). Initially, 255 milliliters of OSE was mixed with 3.62 liters of seawater (2). Afterwards, 100 milliliters of various hydrocarbons was added to one liter of seawater, and the TPH level was measured (3). At the next stage, 100 milliliters of the prepared OSE mixture in the first stage was added to the mixture prepared in the third stage to assess the effect of OSE on TPH degradation. All the experiments were performed at the temperature of 250C. During the research periods, the solution was sampled, and the concentration of TPH was determined via gas chromatography-mass spectrometry (GC-MS) in accordance with the EPA procedure (16). The proof of the TPH destruction effectiveness was evaluated by the decline of the hydrocarbons and calculated by its removal efficiency using the following equation:

where C0 and Ce represent the initial and final TPH concentrations (ppm), respectively.

4. Results and Discussion

Table 1 shows the initial TPH values of each sample and their corresponding removal rates after the OSE II treatment and aeration. Accordingly, the maximum TPH concentration was observed in the Siri crude oil, followed by the crude oil of Bahregan and Lavan. The initial minimum TPH concentration belonged to Qeshm island crude oil. The oil removal rates were within the ranges of 36.28-55.01% and 56.63-70.58% following the treatment with OSE II and 7-15 days of aeration.

| Sample No. | Types of Crude Oil | TPH1 (ppm) | TPH2 (ppm) | Removal, % | TPH3 (ppm) | Removal, % |

|---|---|---|---|---|---|---|

| 1 | Bahregan | 7200 | 4360 | 39.44 | 3123 | 56.63 |

| 2 | Lavan | 7087 | 4516 | 36.28 | 2933 | 58.61 |

| 3 | Qeshm | 5181 | 2980 | 42.48 | 2197 | 57.60 |

| 4 | Siri | 10587 | 4763 | 55.01 | 3115 | 70.58 |

OSE II has been listed on the National Oil and Hazardous Substances Pollution Contingency Plan (NCP) Schedule as a nutrient/enzyme additive and is composed of nitrogen, phosphorus, readily available carbon, and vitamins for the prompt colonization of indigenous and fast growing bacteria (17). In a survey conducted by Zwick et al. (1997), OSE II was reported to enhance hydrocarbon biodegradation in a fuel-contaminated vadose zone (18). Surprisingly, the findings presented in Table 1 imply that higher TPH values led to increased removal efficiencies, which suggests that higher hydrocarbons that might serve as carbon source favor the growth of oil-degrading bacteria. This is consistent with the findings of Tersagh et al. (2016), which demonstrated that bacterial growth increased with the higher substrate concentration (19), implying the utilization of petroleum hydrocarbons in all the treatment options.

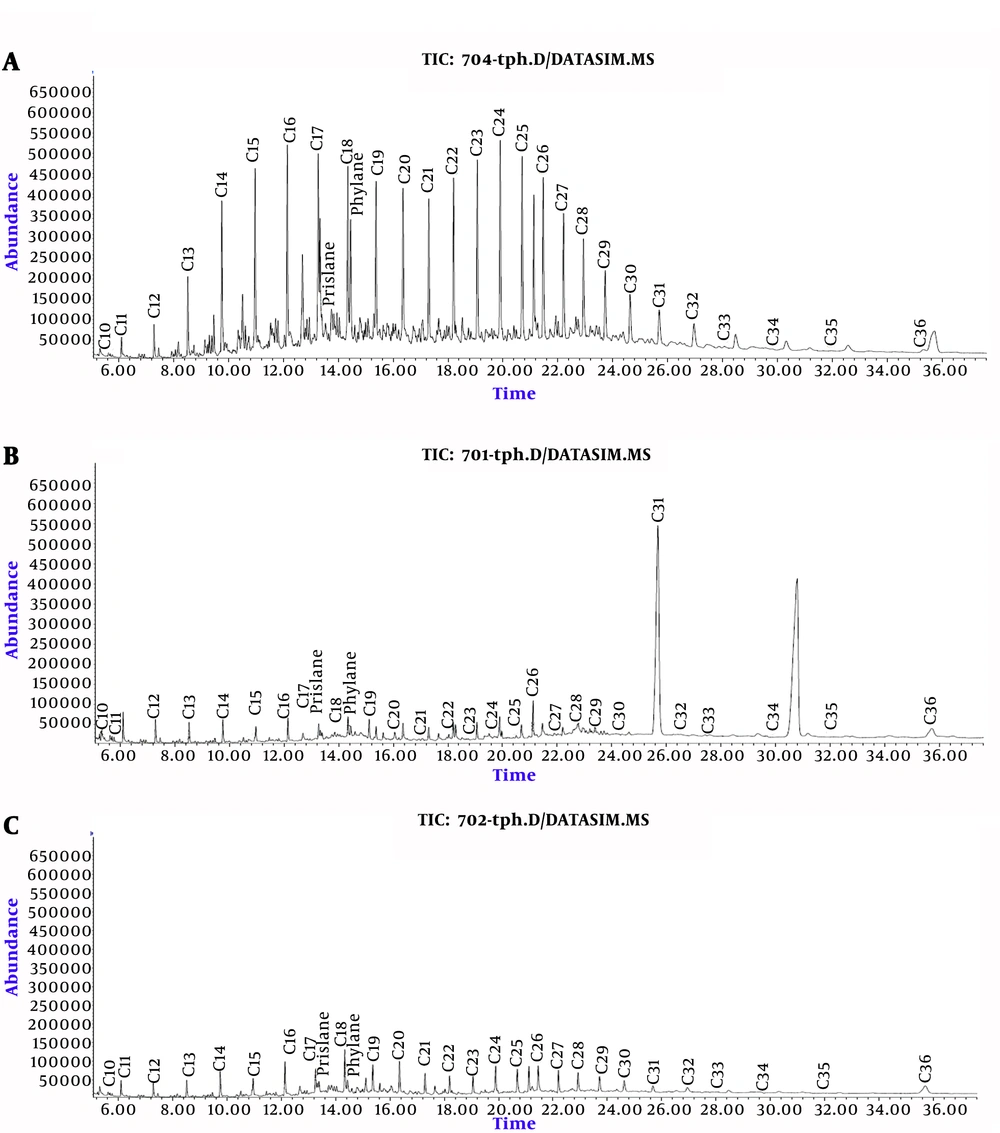

In the current research, the TPH structures were within the range of C10-C36 (Figure 1), indicating the presence of gasoline range organics (C6-C10), diesel range organics (C11-C28), and oil range organics (C12-C36) (20). As is depicted in Figure 1, the TPH concentrations decreased substantially after 15 days of treatment.

5. Conclusion

Although the formulation of OSE II is not publicly known, its mineral nutrients, amylase and protease enzymes, molasses as a carbon source, and oleophilic surfactant could act as effective materials in the removal of oil contaminants.